Intensive aquaculture faces a constant challenge: producing more food for a growing population without compromising the health of our ecosystems. In this search for sustainability, biofloc technology (BFT) has emerged as one of the most promising alternatives. But how truly sustainable is it?

A recent study, published in the journal Sustainability by researchers from the State University of Mato Grosso do Sul, Embrapa Environment, and Itaipu Binacional, conducted an in-depth analysis of a BFT system for cultivating Nile tilapia juveniles (Oreochromis niloticus) to precisely measure its environmental performance. By analyzing the flow of carbon, nitrogen, and phosphorus, the researchers evaluated everything from resource use to pollution potential, offering a clear view of its advantages and challenges.

Key findings

- The system is highly efficient at converting feed into biomass. The fish retained 45.4% of the nitrogen, 46.3% of the phosphorus, and 29.7% of the carbon supplied.

- Water consumption is drastically low, using just 135 liters of water per kilogram of tilapia produced—a crucial advantage in regions with water scarcity.

- Compared to traditional systems like cages, BFT releases a considerably smaller amount of nutrients into the environment, reducing the impact on water bodies.

- High survival rates (98%) and a very efficient apparent feed conversion ratio (FCR) of just 1.05 were achieved.

- The need for constant aeration is its main challenge, with a high energy demand of 114.6 megajoules per kilogram of fish.

The experiment under the microscope: How was sustainability assessed?

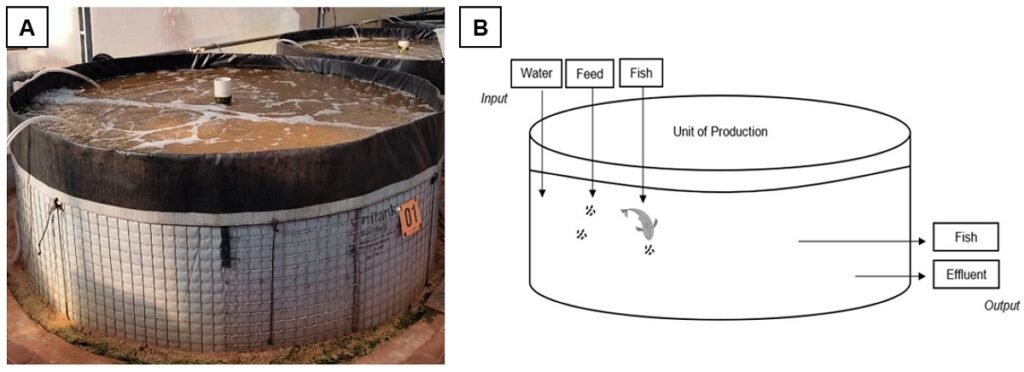

To get a complete picture of the system, the researchers implemented a meticulous trial. Tainara Blatt, an agricultural technician and one of the authors, explains that “during 70 days of experimental cultivation in 4.2 m³ circular tanks, nearly 5,000 tilapia fingerlings were produced in each tank.” Production was maintained at a high density: about 395 fish per cubic meter.

The main approach was to perform a mass balance, a methodology based on the law of conservation. “This type of approach allows for the precise evaluation of carbon, nitrogen, and phosphorus retention and helps estimate pollution potential,” highlights Alex Cardoso, a collaborating researcher on the project. All inputs (feed, water, and initial fish biomass) and outputs (final biomass, liquid and solid effluents) were quantified to understand the fate of each nutrient.

The system’s balance was rigorously managed. Researchers added sugar as a carbon source to maintain a carbon-to-nitrogen ratio of 12:1. This strategy promotes the growth of heterotrophic bacteria, which form the bioflocs, over algae, as demonstrated by the progressive drop in chlorophyll-a levels during cultivation.

The two sides of efficiency

The data obtained reveal a high-performance system with a very interesting environmental profile, although it is not without its challenges.

A protein factory: Superior nutrient use efficiency

The study showed that feed was the main source of nutrients, and the good news is that a large portion of them was efficiently converted into fish. According to the research, the BFT system retained 45.4% of the nitrogen, 46.3% of the phosphorus, and 29.7% of the carbon supplied, primarily from the feed.

To put these numbers in perspective, Embrapa researcher Hamilton Hisano makes a direct comparison: at the end of the cycle, the residual load per ton of fish was 10.24 kg of phosphorus, 46.63 kg of nitrogen, and 442.47 kg of carbon. “These values are much lower than those observed in traditional systems, such as net pens, which can release up to 18.25 kg of phosphorus, 77.50 kg of nitrogen, and 700 kg of carbon per ton of tilapia produced,” Hisano compares.

This efficiency is due to the main characteristic of BFT: nutrient recycling through the action of microorganisms that form the bioflocs.

Stay Always Informed

Join our communities to instantly receive the most important news, reports, and analysis from the aquaculture industry.

Production performance: Tilapia that grow more with less

From an animal husbandry perspective, the results were outstanding. At the end of the period, a 98% survival rate, a final average weight of 20.4 grams, and an apparent feed conversion ratio of just 1.05 were observed. This last index means that only 1.05 kg of feed was needed to produce 1 kg of fish.

“These indicators demonstrate not only good zootechnical performance but also the feed efficiency of tilapia in the BFT system,” relates Blatt. She attributes this success to the “consumption of the microbial floc as a complementary food, which, besides having a high protein content, also contains probiotic bacteria.”

Sustainability in practice: Water, energy, and biodiversity

The study also applied a set of indicators to obtain a holistic view of the system’s sustainability.

The resource dilemma: Minimal water use vs. High energy consumption

This is where the BFT system shows its two faces. On the one hand, its water efficiency is exceptional. BFT uses just 135 liters of water per kilogram of tilapia produced. This low need for water exchange and its reuse not only reduces the risk of contamination but also enhances the use of BFT in regions with water scarcity or in urban areas.

However, the main challenge identified was the high energy consumption. For André Watanabe and Celso Buglione of Itaipu Binacional, this is the critical point. Consumption was estimated at 114.6 megajoules per kilogram of fish produced, a value associated with the need for continuous aeration to keep solids suspended and maintain dissolved oxygen. To expand the adoption of BFT, the researchers point to the urgent need to invest in renewable energy sources and improve equipment efficiency.

A closed system: Lower impact and greater biosecurity

Regarding the risk to biodiversity, BFT received a moderate impact rating (level 4), lower than open systems like cages (level 5). “As a closed system, BFT provides greater control over production and the waste generated,” highlights Tainara Blatt. This configuration prevents species from escaping and reduces the spread of pathogens, increasing the overall biosecurity of the operation.

Looking to the future: From waste to resources and beyond

Another highlight of the work was the possibility of reusing the solid waste removed from the system. With the potential to be transformed into fertilizers or feed ingredients, these byproducts can add value and contribute to the circularity of production, reinforcing the sustainable nature of BFT.

Despite the scarcity of studies that evaluate the system in an integrated way, the researchers emphasize that tools like life cycle analysis and carbon footprint calculations can be incorporated in the future to more accurately measure the environmental impacts of biofloc fish farming.

Based on the data obtained, the study concludes that the BFT system offers a technically viable and environmentally safer solution for the intensification of aquaculture. Its rational use of resources, ability to retain nutrients, and control over impacts position it as a strategic alternative for aquatic protein production in the face of growing pressures for food security and ecosystem preservation.

Reference (open access)

Blatt, T. L. d. S., Cardoso, A. J. d. S., Watanabe, A. L., Neto, C. C. B., & Hisano, H. (2025). Environmental Sustainability of Nile Tilapia Reared in Biofloc Technology (BFT) System: Evaluation of Carbon, Nitrogen, and Phosphorus Dynamics and Indicators of Sustainability. Sustainability, 17(13), 5670. https://doi.org/10.3390/su17135670

Editor at the digital magazine AquaHoy. He holds a degree in Aquaculture Biology from the National University of Santa (UNS) and a Master’s degree in Science and Innovation Management from the Polytechnic University of Valencia, with postgraduate diplomas in Business Innovation and Innovation Management. He possesses extensive experience in the aquaculture and fisheries sector, having led the Fisheries Innovation Unit of the National Program for Innovation in Fisheries and Aquaculture (PNIPA). He has served as a senior consultant in technology watch, an innovation project formulator and advisor, and a lecturer at UNS. He is a member of the Peruvian College of Biologists and was recognized by the World Aquaculture Society (WAS) in 2016 for his contribution to aquaculture.