The growing global demand for seafood products has driven aquaculture to unprecedented expansion, making it the fastest-growing food production sector in the last three decades. However, this intensification is not without challenges, such as water pollution and inefficient resource use. In this context, biofloc technology (BFT) has emerged as a sustainable solution, but its success depends on extremely precise control and monitoring.

A recent review study published by researchers from the University of Tabuk explores how the integration of artificial intelligence (AI) and the Internet of Things (IoT) can overcome these barriers, giving way to “smart biofloc systems”. This technological synergy promises to automate processes, optimize resources, and ultimately make aquaculture more resilient, productive, and environmentally friendly.

What is biofloc technology, and why is it so sensitive?

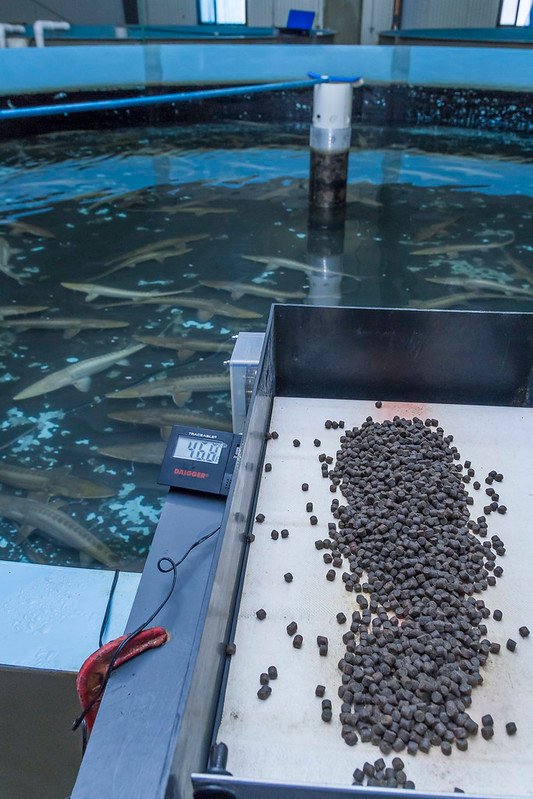

Biofloc technology is an innovative cultivation system that leverages microbial communities to recycle nutrients within the same culture tank. These microbes, mainly heterotrophic bacteria, convert nitrogenous waste (like ammonia) into microbial protein, which serves as a constant supplementary food source for fish or shrimp. This not only improves water quality with minimal or no water exchange but also reduces feed costs and improves the health of the cultivated organisms.

However, the system is delicate. Small fluctuations in parameters such as dissolved oxygen (DO), pH, or the carbon-to-nitrogen (C:N) ratio can destabilize the microbial community and cause mass mortalities. This is where technology comes into play.

The arrival of AI and IoT in biofloc

To address the sensitivity of BFT systems, smart aquaculture integrates advanced technologies. The concept is simple yet powerful:

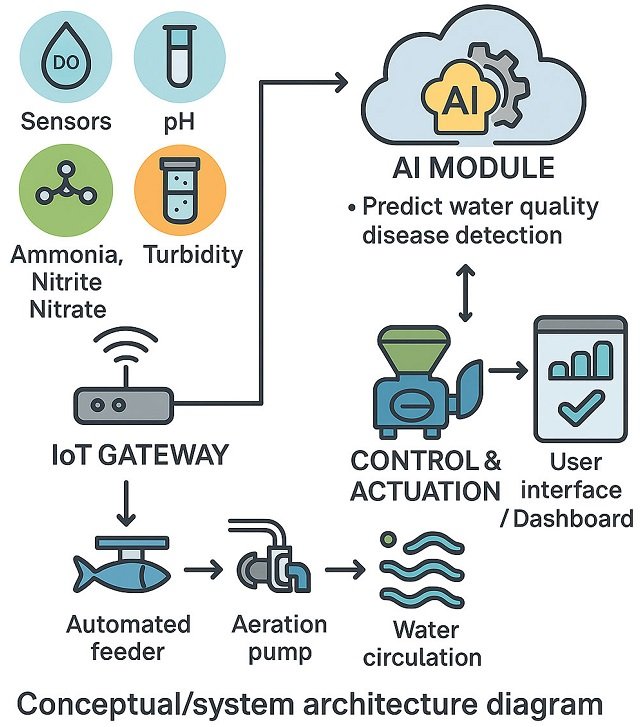

- Sensors (IoT): Devices such as pH, dissolved oxygen, temperature, and turbidity sensors are deployed in the tanks to collect real-time data on water quality.

- Connectivity: This data is transmitted through an IoT Gateway to a central platform, often in the cloud.

- Analysis (AI): Artificial intelligence algorithms analyze this constant flow of data to identify patterns, predict trends, and make informed decisions.

- Action (Automation): Based on the AI analysis, the system can automatically activate aerators, feeders, or pumps to maintain optimal conditions without constant human intervention.

This approach transforms a manual and reactive system into an automated, predictive, and proactive one.

Practical applications: beyond the theory

The study highlights several key applications where the combination of AI and IoT is demonstrating a tangible impact:

Predictive water quality management

Instead of reacting to problems like a drop in oxygen, AI models can predict them. Algorithms like Long Short-Term Memory (LSTM) neural networks are especially effective for analyzing time-series data and forecasting water quality fluctuations hours in advance. This allows producers to take preventive measures, avoiding stressful conditions or mortality.

Feed optimization

Feed accounts for up to 50-60% of operational costs in aquaculture. Overfeeding is not only a waste of money but also deteriorates water quality. Smart feeding systems use cameras and sensors to analyze fish behavior and appetite in real-time. AI algorithms, such as Convolutional Neural Networks (CNNs), can interpret this data to dispense the right amount of feed at the precise moment, reducing waste by up to 21% and improving profitability, as demonstrated by commercial success stories like eFishery in Indonesia.

Stay Always Informed

Join our communities to instantly receive the most important news, reports, and analysis from the aquaculture industry.

Early disease detection

AI is also revolutionizing fish health. Computer vision models like YOLOv8 can analyze images or videos of fish to detect visual signs of disease or stress, such as lesions, lethargy, or erratic swimming patterns. This early detection is crucial for isolating problems before they spread, reducing the need for antibiotics and minimizing economic losses.

Quantifiable economic and environmental impact

Adopting smart biofloc systems is not just a technological upgrade but a strategic investment with clear benefits:

- Cost reduction: Optimizing feeding and reducing mortality from disease and poor water quality have a direct impact on profitability. One case study showed a cost saving of 10% and a 12% improvement in feeding efficiency.

- Increased productivity: By maintaining stable and optimal environmental conditions, fish experience less stress, which translates into better growth and survival rates.

- Environmental sustainability: BFT systems, by their nature of minimal water exchange, drastically reduce the discharge of nutrient-rich effluents into the environment. AI and IoT enhance this advantage by making the system even more efficient, lowering the carbon footprint and ecological impact of aquaculture production.

Challenges and the path forward

Despite their immense potential, the widespread adoption of these technologies faces obstacles. High initial implementation costs, the need for internet connectivity in rural areas, the lack of data protocol standardization, and the need for trained technical staff are significant barriers.

To overcome these challenges, future research is focused on developing “edge-AI” systems (processing data on the device itself) to reduce dependency on the cloud, the use of blockchain to ensure data transparency, and the design of adaptive control algorithms that learn and improve over time.

Conclusion

The convergence of biofloc technology with artificial intelligence and the Internet of Things represents a paradigm shift for aquaculture. We are moving from management based on observation and reaction to an era of automated, predictive, and data-driven control. These smart biofloc systems not only address the operational challenges of the present but also pave the way for a future where aquatic food production is more efficient, profitable, and, above all, sustainable.

Reference (open access)

Alghamdi, M., & Haraz, Y. G. (2025). Smart Biofloc Systems: Leveraging Artificial Intelligence (AI) and Internet of Things (IoT) for Sustainable Aquaculture Practices. Processes, 13(7), 2204. https://doi.org/10.3390/pr13072204

Editor at the digital magazine AquaHoy. He holds a degree in Aquaculture Biology from the National University of Santa (UNS) and a Master’s degree in Science and Innovation Management from the Polytechnic University of Valencia, with postgraduate diplomas in Business Innovation and Innovation Management. He possesses extensive experience in the aquaculture and fisheries sector, having led the Fisheries Innovation Unit of the National Program for Innovation in Fisheries and Aquaculture (PNIPA). He has served as a senior consultant in technology watch, an innovation project formulator and advisor, and a lecturer at UNS. He is a member of the Peruvian College of Biologists and was recognized by the World Aquaculture Society (WAS) in 2016 for his contribution to aquaculture.