One of the most critical and costly factors in the aquaculture industry is feeding, which can account for up to 50-70% of total operating costs. Therefore, efficient feed management, including feeding methods and the use of appropriate feeders, is essential for profitability and sustainability.

This article delves into the world of aquaculture feeders, exploring their evolution, the different types available, the technologies driving them, and their strategic impact on modern aquaculture. We will examine how the transition from manual methods to automated systems, such as automatic feeders, is revolutionizing the industry.

The Importance of Feeding in Aquaculture

Feeding is not simply about providing sustenance; it is a precise practice that directly impacts:

- Growth Rates: The quantity, quality, and frequency of feeding determine how quickly cultured organisms grow.

- Feed Conversion Ratio (FCR): A low FCR (the amount of feed needed to produce one unit of body weight) is a key indicator of efficiency and profitability. Optimizing FCR reduces feed waste and costs.

- Animal Health and Welfare: Adequate nutrition and regular feeding reduce stress, improve disease resistance, and promote the overall welfare of fish. Irregular feeding can cause stress and mortality.

- Water Quality: Excess uneaten feed decomposes, releasing ammonia and other nitrogenous compounds that degrade water quality, increase oxygen demand, and can be toxic to aquatic animals.

- Environmental Sustainability: Efficient feeding minimizes nutrient waste into the surrounding environment, reducing the ecological impact of aquaculture.

The challenge lies in delivering the right amount of feed at the right time, adapted to the specific needs of the species, its life stage, and environmental conditions.

Evolution of Feeding Methods: From Manual to Automatic

Historically, feeding in aquaculture was done manually, often by hand-casting feed from the banks of ponds or from boats; however, this is laborious and can lead to incorrect feeding (underfeeding or overfeeding) due to workers’ lack of experience and the influence of environmental factors such as water temperature on fish appetite (Kai et al., 2025).

While this manual feeding method allows for direct observation of the fish, it presents several significant disadvantages that can be grouped as follows:

- Labor-Intensive: It requires dedicated personnel, increasing labor costs.

- Inconsistency: The amount and distribution of feed can vary significantly between feedings and workers.

- Frequency Limitations: It is difficult to perform frequent, small feedings, which are often more beneficial for certain species.

- Weather Dependency: Adverse weather conditions can disrupt manual feeding schedules.

- Increased Waste: Uneven distribution can lead to some feed not being consumed, thereby increasing production costs.

To overcome these challenges, the industry has developed and adopted various types of feeders.

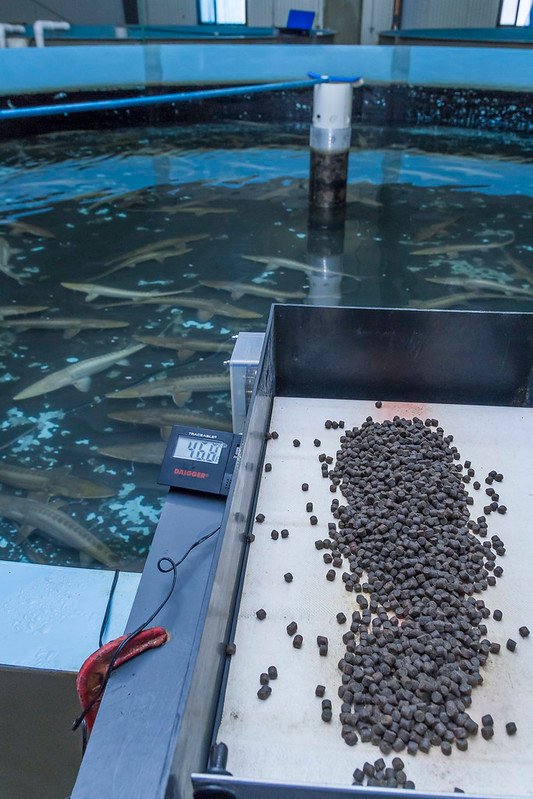

Types of aquaculture feeders

Aquaculture feeders can be broadly classified into demand feeders and automatic feeders.

Demand Feeders

These feeders dispense feed when fish interact with a triggering mechanism. According to Kai et al., (2025), knowledge of fish hunger and satiety behavior is crucial for the design of demand feeders. Common types of demand feeders include:

- Pendulum Feeders: These have a rod or pendulum hanging in the water. When fish strike or shake the rod seeking food, a predetermined amount of feed is released.

- Advantages: They do not require electricity (in basic models), allow fish to feed according to their appetite, and can reduce competition and stress in some species. Useful for studying fish appetite.

- Disadvantages: They may not be suitable for small fish that cannot activate the mechanism, there is a risk of overfeeding if the trigger is too sensitive or accidentally activated, and activation can be dominated by a few individuals.

- Submerged-Plate Feeders: These release more feed once the fish have consumed the feed from a submerged plate. They are more effective for small fish.

Although demand feeders offer advantages, the risk of overfeeding and lack of precise control have led to wider adoption of automatic feeders. However, recent research with modern demand systems using sensors (e.g., acoustic) to measure appetite shows promising results, even surpassing automatic feeders in some growth metrics for certain species like the shrimp Litopenaeus vannamei.

Automatic Feeders

These devices dispense feed at pre-programmed times and quantities, offering much greater control over the feeding process. They are the cornerstone of modern automatic feeding.

Thornburg (2025) highlights that automatic feeders are revolutionizing aquaculture by enabling precise and controlled feeding regimens that optimize growth, reduce feed waste, and enhance the overall efficiency of farming operations; meanwhile, Ahmad et al., (2025) define automatic feeders as “a device designed to control feeding schedules and dispense feed only at predetermined intervals.”

For example, Chaidir et al., (2025) concluded that automatic fish feeding technology has a positive effect on feed efficiency, survival rate, and specific growth rate of tilapia, which can result in earlier harvests and higher yields.

Typical Components

Most automatic feeders for growing fish and shrimp consist of:

- Hopper: A container for storing the feed. The material should prevent moisture ingress.

- Doser/Dispenser: A mechanism (often a screw auger or servo-controlled) driven by a motor that regulates the amount of feed dispensed.

- Motor(s): To drive the doser and, in many cases, a spreader. Servo motors are common due to their precision and energy efficiency.

- Spreader/Thrower: A motorized fan or propeller that distributes the feed over the water surface (not present in all designs).

- Control System: Often based on timers, PLCs (Programmable Logic Controllers), microcontrollers (like Arduino), or more advanced systems with sensors and Artificial Intelligence.

Power Sources

Automatic feeders can be powered by mains electricity, batteries, or, increasingly, by solar photovoltaic (PV) energy, especially in remote or off-grid installations. Solar-powered feeders are a sustainable and practical option.

Common Design Types

- Screw Auger Feeders: These use a motor to turn a screw that drops feed by gravity directly below the feeder. They consume less energy but have limited dispersal. Suitable for 1-10 mm feeds.

- Spreader/Thrower Feeders: These use a second motor to spin a disc or fan that throws the feed over a wider area. They consume more energy but achieve better distribution. Suitable for 4-20 mm feeds.

Automatic Feeding System Configurations

Beyond the individual feeder design, different system configurations exist to suit various scales and types of aquaculture facilities (Thornburg, 2025):

- Single Feeder: The most common type, with its own hopper and dosing/spreading mechanism. Low maintenance, but capacity is limited per hopper.

- Moving Feeder: Systems mounted on trucks or barges that travel between different ponds or cages, refilling at a central location. High feeding capacity, but requires an operator for the vehicle.

- Rail Feeder: Feeder modules that move along a fixed rail system installed in the facility, dispensing feed into different tanks or enclosures. Requires rail installation.

- Drag Chain Feeder: A tube or feeding line runs through the enclosures, and an internal chain drags and pushes feed to designated outlets. Requires pipe installation.

- Centralized Feeder: A large central feed silo stores the feed, which is then distributed to multiple tanks or cages via pneumatic tubes, conveyors, or other systems. High capacity, suitable for large operations, but requires extensive pipe installation.

The choice of configuration depends on the farm size, the type of culture system (ponds, RAS tanks, open-water cages), the species being cultured, and the budget. Centralized and piped systems (pneumatic, drag chain) are common in hatcheries, pre-grow, and ongrowing stages.

Key Features and Considerations for Choosing a aquaculture Feeder

When selecting or implementing an aquaculture feeder, whether for a small tank or a commercial farm, several factors are crucial:

- Accuracy and Consistency: Can the feeder reliably dispense the correct amount of feed in each cycle?

- Hopper Capacity: How much feed can it store? This determines the refilling frequency.

- Feed Size Range: Is it compatible with the pellet size or type of feed used? Hatcheries may require feeders for microdiets (50-1000 µm) and sometimes live feed, while ongrowing uses larger pellets (4-20 mm).

- Dispersal Area: Does it adequately cover the desired feeding area? (Important for large ponds and cages). Spreader feeders offer wider coverage.

- Programming and Control: How easy is it to set up and adjust feeding schedules and amounts? Modern systems offer digital interfaces, PLCs, or app-based control. Being able to vary intervals and duration is crucial.

- Reliability and Durability: Is it built to withstand the aquaculture environment (humidity, salinity)? Does it require much maintenance?

- Power Source: Does it require electricity? Is it compatible with solar power?

- Cost: The initial investment varies greatly depending on the type, size, and technology.

- Ease of Feeder Setup: Is it easy to install and operate? Are the instructions clear?

- Additional Features: Some offer feed level monitoring with alerts (e.g., SMS via GSM), sensor integration (temperature, dissolved oxygen), or Internet of Things (IoT) connectivity.

Benefits of Using Automatic Feeders

The adoption of automatic feeding devices offers numerous advantages over manual feeding:

- Feeding Optimization: They allow for the implementation of precise feeding strategies (quantity, frequency, schedule) adapted to the species and life stage (Thornburg, 2025).

- Reduced Labor Costs: They decrease the need for personnel for manual feeding.

- Improved FCR: Precise and frequent feeding reduces waste, improving the feed conversion ratio.

- Accelerated Growth: Optimized feeding schedules can lead to faster and more homogeneous growth rates. Comparative studies show that automatic and demand feeding often outperform manual feeding in terms of weight gain and weekly growth.

- Improved Water Quality: By minimizing uneaten feed, nutrient load and water pollution are reduced.

- Stress Reduction: Regular and predictable feeding can decrease stress and competition among fish.

- Operational Flexibility: They allow feeding during adverse weather conditions, weekends, or vacations.

- Monitoring and Data Management: Advanced systems can record feeding data, integrate with environmental sensors, and allow remote management.

Challenges and Limitations of Using Automatic Feeders

Despite the benefits, there are challenges associated with automatic feeders:

- Initial Cost: The investment can be significant, especially for advanced or centralized systems.

- Maintenance and Reliability: They require regular maintenance (cleaning, calibration) and can suffer mechanical or electronic breakdowns. Reliability in harsh environments is a concern.

- Risk of Failures: A malfunction could lead to prolonged underfeeding or overfeeding if not detected promptly.

- Clogging: Feed can clump due to moisture, or the feed type might clog the dosing mechanism. Keeping the feed dry is crucial.

- Power Requirement: Most require a reliable power source.

- Technical Complexity: Advanced systems may require technical expertise for their configuration (setup), operation, and troubleshooting.

- Security (IoT Systems): Devices connected to the internet can be vulnerable to cyberattacks if not properly secured.

Optimizing Feeding Strategies with Automatic aquaculture Feeders

Simply installing an automatic feeder does not guarantee optimal results. It is crucial to refine the feeding strategy:

- Species-Specific Considerations: Each species has different nutritional requirements and feeding behaviors. Some prefer to feed during the day, others at night.

- Type and Quality of Aquaculture Feed: Using the appropriate pellet size for the feeder and the fish’s life stage is essential. The quality and formulation of the feed, often provided by aquaculture feed production companies, directly impact growth and FCR. Alternative and sustainable ingredients like insect meal are being explored.

- Frequency and Schedule: Determining the optimal frequency (small, frequent feedings vs. fewer large feedings) and the best times of day to feed, based on the species’ natural behavior and environmental conditions. Timers are a key feature.

- Environmental Monitoring: Factors such as water temperature, dissolved oxygen, and pH affect fish appetite and metabolism. Advanced systems can adjust feeding based on real-time sensor data.

- Behavioral Observation: Observing how fish respond to feeding (activity, consumption) remains important, even with automatic systems.

Technological Advancements in Aquaculture Feeders

Technology is transforming automatic feeders, making them ‘smarter’ and more efficient. In this regard, Ramesh et al., (2021) identified the critical need for intelligent feeding systems in aquaculture and detailed a proposed conceptual framework integrating various technologies like AI, machine learning, computer vision, and IoT to achieve more efficient, precise, and automated feeding, with multiple benefits for the industry, based on:

Sensors

- Feed Level Sensors: Detect when the hopper needs refilling and can send alerts. Limit switches are an option.

- Water Quality Sensors: Measure DO, temperature, pH, ammonia, etc., to adjust feeding.

- Acoustic/Visual Sensors: Detect feeding activity or fish behavior to adjust feed delivery in real-time (demand or behavior-based feeding). Peixoto and Soares (2025) highlight the use of passive acoustic monitoring (PAM) as a novel tool to investigate shrimp behavior and optimize feed management in aquaculture.

Internet of Things (IoT)

Connects feeders and sensors to the Internet, enabling remote monitoring and control via mobile or web applications. Facilitates the management of multiple feeders and data collection. Abu-Khadrah et al., (2022) developed an intelligent IoT-based fish feeding and monitoring system. This system mainly consists of two modules: one for fish feeding and another for monitoring water characteristics and level; meanwhile, Basino et al., (2025) managed to design and program a functional control system for the ROMF using Arduino Mega 2560 and Wemos D1 Mini, demonstrating its ability to operate the platform and feeding system remotely.

Artificial Intelligence (AI) and Machine Learning (ML)

Kai et al., (2025) describes that artificial intelligence (AI) offers a new approach for the development and application of intelligent feeding control in aquaculture. AI is used to analyze data from sensors, fish behavior, and environmental factors to predict feeding needs, optimize schedules and quantities, and make intelligent feeding decisions. Deep neural networks are a tool.

Computer Vision (Machine Vision)

Zhang et al., (2023) stated that computer vision has great potential to revolutionize feeding in aquaculture, making it smarter, more precise, and efficient. It is employed to monitor feed consumption in trays, estimate biomass, and analyze fish behavior.

Robotics

Feeding robot prototypes are being developed, sometimes mobile and solar-powered (Abdul, 2023 and Abdul and Dermawan, 2024), to further automate feed delivery in larger facilities.

Mobile Communications (GSM)

Allow sending SMS alerts to operators about low feed levels or abnormal environmental conditions (e.g., temperature). Uddin et al., (2016) designed an intelligent automatic fish feeder, including feed level and water temperature monitoring with SMS updates, all controlled by an Arduino microcontroller.

Microcontrollers (Arduino, PIC)

Affordable and flexible platforms for building and controlling custom automatic feeders, often used in development or DIY projects. For example, Adimulam et al., (2024) developed an IoT-based automatic feed dispenser; this system uses ultrasonic sensors, Arduino technology, and a Bluetooth module.

Automatic Feeders for Home Aquariums

While many principles apply, feeders for home aquariums have specific considerations:

- Scale: They are much smaller, with lower capacity hoppers.

- Feed Type: Primarily designed for flakes, granules, or small pellets.

- Precision: Overdosing can quickly pollute a small water volume.

- Reliability: Crucial for owners going on vacation. Forum discussions (like Reddit) suggest reliability varies among models and brands (Eheim, Fish Mate are often mentioned).

- Moisture: A common problem is aquarium humidity causing food to clump in the hopper. Some models advertise moisture-proof features.

- Necessity: For short absences (a few days), many experienced aquarists suggest healthy fish can go without eating, and a feeder might be unnecessary or even introduce risks if not properly tested.

- Popular Brands: Brands like Eheim, Fish Mate, Fluval, FREESEA, Petbank, Top Fin, Tetra are commonly found in stores like Amazon and Petsmart.

Are automatic feeders good for aquariums? They can be, especially for longer absences or maintaining a very regular feeding schedule, but it is vital to choose a reliable model, test it thoroughly before a prolonged absence, and ensure it does not overdose the feed.

The Future of Feeders in Aquaculture

The trend is towards increasingly intelligent, integrated, and sustainable feeding systems:

- Greater Integration of Sensors and AI: Systems that adjust feeding not only based on schedule but also according to the fish’s actual appetite, behavior, estimated biomass, and real-time environmental conditions. Thornburg (2025) indicates that integrating artificial intelligence (AI) and machine learning algorithms has the potential to enable adaptive feeding strategies that optimize feed utilization and enhance overall farm productivity.

- Data Analysis: Use of big data collected by feeding systems to continuously refine strategies and predict future needs.

- Sustainability: Greater focus on energy efficiency (solar power), reduction of feed waste, and use of sustainable ingredients.

- Complete Automation: Autonomous feeding robots and more sophisticated centralized management systems.

- Improved Reliability: Development of more robust materials and designs for demanding aquaculture environments.

Conclusion

Feeders, and particularly automatic feeding systems, have become indispensable tools in modern aquaculture. They have evolved from simple fish-activated mechanisms to sophisticated AI-controlled devices, integrated with sensors and connected via IoT. By enabling precise and optimized feeding, they significantly reduce labor and feed costs, improve growth rates and fish health, and minimize the environmental impact of aquaculture.

While challenges such as initial cost and the need for maintenance exist, the benefits largely outweigh the disadvantages, especially as technology continues to advance. From automatic dispensers for home aquariums to large-scale centralized systems for commercial farms, automatic feeding technology is helping to improve efficiency in the aquaculture industry.

References

Abdul Kadir Muhammad, Dermawan; A fish feeding robot prototype using a solar panel and an internet of things – based monitoring system. AIP Conf. Proc. 7 June 2023; 2727 (1): 030007. https://doi.org/10.1063/5.0141442

Abdul Kadir Muhammad, Dermawan Dermawan; Control system development of a fish feeding robot equipped with a water level control. AIP Conf. Proc. 10 July 2024; 3140 (1): 030014. https://doi.org/10.1063/5.0221320

Abu-Khadrah A., G. F. Issa, S. Aslam, M. Shahzad, K. Ateeq and M. Hussain, “IoT Based Smart Fish-Feeder and Monitoring System,” 2022 International Conference on Business Analytics for Technology and Security (ICBATS), Dubai, United Arab Emirates, 2022, pp. 1-4, doi: 10.1109/ICBATS54253.2022.9759058.

Adimulam, R. P., Kokkiligadda, V., & Polagani, A. (2024, September). Automatic Feed Dispenser for Aquaculture using Arduino Technology. In 2024 3rd International Conference for Advancement in Technology (ICONAT) (pp. 1-5). IEEE.

Ahmad dar, S., Kumar, S., Saini, V.P. (2025). Smart Fish Feeding System in Aquaculture. In: Ganie, P.A., Posti, R., Pandey, P.K. (eds) Information Technology in Fisheries and Aquaculture. Springer, Singapore. https://doi.org/10.1007/978-981-97-8553-7_7

Basino, Wibowoa, B., Frianda, D. N., Susanto, I., Ridhwan, R. Z., Ramli, T. H., & Saputra, R. S. H. (2025). Control system design of the romf (remotely operated moving feeder). Multidisciplinary Science Journal, 7(9), 2025432. https://doi.org/10.31893/multiscience.2025432

Chaidir A. R., HerdiyantoD. W., EskaA. C., & KalandroG. D. (2025). THE EFFECT OF AUTOMATIC FISH FEEDING TECHNOLOGY ON THE QUALITY OF TILAPIA FISH CULTURE PRODUCTS: PENGARUH TEKNOLOGI PEMBERI PAKAN IKAN OTOMATIS TERHADAP KUALITAS HASIL BUDIDAYA IKAN NILA. Jurnal Teknologi Perikanan Dan Kelautan, 16(1), 44-51. https://doi.org/10.24319/jtpk.16.44-51

KAI, T., HSEIN-LOONG, A. U., GUAN, L., KIN, T. K. T., ALFRED, R., TAMRIN, M. L. M., … & LEONG-SENG, L. I. M. (2025). APPLICATION OF FEEDING MACHINES IN EPINEPHELINAE GROUPERS GROW-OUT CULTURE: A BRIEF OVERVIEW. Journal of Sustainability Science and Management, 20(2), 406-418.

Peixoto, S., & Soares, R. (2025). Recent Advances and Applications of Passive Acoustic Monitoring in Assessing Shrimp Feeding Behaviour Under Laboratory and Farm Conditions. Reviews in Aquaculture, 17(1), e12978. https://doi.org/10.1111/raq.12978

Ramesh, P., Jasmin S., A., Puja U., T., Shrree R. S., D., & Tanveer, M. (2021). Development of AI Enabled Smart Feeding System for Aquaculture Farm – A State-of-Art Approach. Biotica Research Today, 3(8), 683-686

Thornburg, J. (2025). Feed the fish: A review of aquaculture feeders and their strategic implementation. Journal of the World Aquaculture Society, 56(2), e70016. https://doi.org/10.1111/jwas.70016

Uddin, M. N., Rashid, M., Mostafa, M., Belayet, H., Salam, S. M., Nithe, N., … & Aziz, A. (2016). Development of automatic fish feeder. Global Journal of Researches in engineering: A mechanical and Mechanics Engineering, 16(2), 11.

Zhang, L., Li, B., Sun, X., Hong, Q., & Duan, Q. (2023). Intelligent fish feeding based on machine vision: A review. Biosystems Engineering, 231, 133-164. https://doi.org/10.1016/j.biosystemseng.2023.05.010

Editor at the digital magazine AquaHoy. He holds a degree in Aquaculture Biology from the National University of Santa (UNS) and a Master’s degree in Science and Innovation Management from the Polytechnic University of Valencia, with postgraduate diplomas in Business Innovation and Innovation Management. He possesses extensive experience in the aquaculture and fisheries sector, having led the Fisheries Innovation Unit of the National Program for Innovation in Fisheries and Aquaculture (PNIPA). He has served as a senior consultant in technology watch, an innovation project formulator and advisor, and a lecturer at UNS. He is a member of the Peruvian College of Biologists and was recognized by the World Aquaculture Society (WAS) in 2016 for his contribution to aquaculture.