Meeting the growing global demand for seafood presents a significant challenge. Traditional nearshore aquaculture faces space limitations and environmental concerns. Offshore aquaculture offers a potential solution, but it introduces new challenges due to the harsher marine environment, characterized by stronger waves and currents.

A team of scientists from The University of Queensland, the Blue Economy Cooperative Research Centre, Griffith University, and Huon Aquaculture Company Pty Ltd., published a study proposing an innovative offshore fish pen design called SeaFisher. This novel system addresses the challenges of fish farming in open seas and provides a solution that is cost-effective and resilient.

Professor Chien Ming Wang from the School of Civil Engineering said that competition for space in protected coastal waters meant the industry needed to move farther offshore, leading the Blue Economy Cooperative Research Centre to commission the project.

Key Features of SeaFisher

Traditional offshore fish farms often struggle to withstand the harsh marine environment, characterized by strong waves and currents. This can lead to structural damage, leaks, and even fish mortality. “Our design will help fish farms meet the growing demand for seafood affordably and sustainably,” said Professor Wang.

“Moving to deeper and colder waters is excellent for the ocean environment and the health and well-being of fish, but if a pen is too flimsy, the ocean’s big waves during storms would quickly tear it apart.”

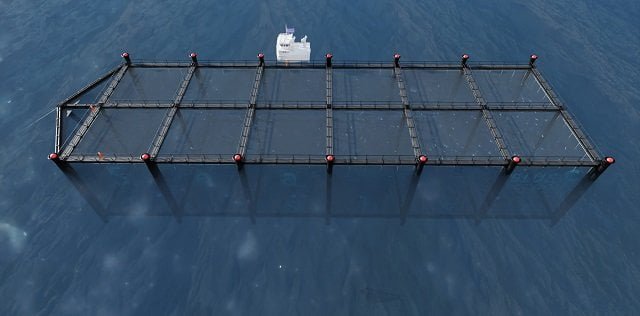

“This solution, called SeaFisher, clusters high-density polyethylene (HDPE) pipes with custom supports and connectors to create a framework that provides strength in a lightweight structure.

SeaFisher addresses fish farmers’ concerns with several key features:

- Modular Design: SeaFisher uses modular cubic pens, allowing for flexible configuration and easy expansion as needed.

- Durable Materials: The frame is built with high-density polyethylene (HDPE), known for its flexibility and durability in hostile marine environments.

- Innovative Connections: Specially designed supports and connectors facilitate efficient assembly of the HDPE pipes forming the SeaFisher structure.

- Single-Point Mooring: This approach minimizes environmental impact and collision risks while improving waste dispersion.

- Climate-Adaptive Ballasting: SeaFisher features unique ballast tubes on its upper surface. During severe weather events, these tubes can be filled with water, allowing the entire structure to submerge and escape the worst of the surface waves.

“To keep the pen and fish safe, water pumps fill the pipes so it can submerge in case of a storm, and when the danger has passed, that ballast can be emptied so the pen rises back to the surface,” highlighted Professor Wang.

“A frontal shield deflects debris around the pen, while a soft, reinforced PET plastic net keeps predators at bay.”

Stay Always Informed

Join our communities to instantly receive the most important news, reports, and analysis from the aquaculture industry.

Engineering Excellence

The paper delves into the details of the engineering design and hydroelastic analysis of SeaFisher.

- Hydrostatic Analysis: This analysis determines appropriate materials and sizes for various components, ensuring the structure’s ability to withstand anticipated loads.

- Hydroelastic Analysis: Using specialized software (AquaSim v.2.17.3), the hydroelastic responses of SeaFisher are investigated under different sea state conditions. This analysis confirms that the design, including the mooring system, is suitable in terms of strength and stiffness for significant wave heights of up to 8 meters and current speeds of up to 0.8 meters per second.

Cost of the Pen

Researchers estimate that the pen will initially cost around 6 million dollars, a fraction of the cost of other more rigid offshore aquaculture structures used in the northern hemisphere.

Professor Wang says models show SeaFisher could rear ten times more fish than other offshore pens on the market, some of which cost up to 180 million dollars.

“It’s a modular system of 20-cubic-meter cages, joined two by two to allow easy access for monitoring, feeding, and harvesting fish populations,” he said.

“We estimate each cubic cage could comfortably hold 24,000 fully grown 5-kilogram fish.

“It could be used to farm different species of fish side by side and adapted to cultivate seaweed, using the waste from the fish pens to fertilize plant cultivation.

“By mooring the pen with a chain attached to a single suction anchor allowing it to move with water currents, the impact on the ocean floor is minimal.”

Conclusion

SeaFisher has the potential to be a game-changer for offshore aquaculture. Its affordability, modular design, and climate adaptation capabilities offer significant advantages over existing systems. The design has been patented, and scale models will now be tested before prototypes are built.

This innovative approach could pave the way for more sustainable and productive aquaculture practices, ultimately contributing to a safe and healthy seafood supply for the future. The study adds to various efforts to make open-ocean aquaculture a reality.

The Blue Economy Cooperative Research Centre (CRC)

The Blue Economy Cooperative Research Centre (CRC) is established and supported under the Australian Government’s CRC Program, grant number CRC-20180101. The CRC Program supports industry-led collaborations between industry, researchers, and the community. Further information about the CRC Program is available at www.business.gov.au.

Reference (open access)

Wang, Chien-Ming, Yun-Il Chu, Joerg Baumeister, Hong Zhang, Yi-Ping Qiao, Hassan Karampour, Dong-Sheng Jeng, and Leigh Savage. 2023. “SeaFisher—A Submersible High-Density Polyethylene Offshore Fish Pen” Journal of Marine Science and Engineering 11, no. 9: 1795. https://doi.org/10.3390/jmse11091795

Editor at the digital magazine AquaHoy. He holds a degree in Aquaculture Biology from the National University of Santa (UNS) and a Master’s degree in Science and Innovation Management from the Polytechnic University of Valencia, with postgraduate diplomas in Business Innovation and Innovation Management. He possesses extensive experience in the aquaculture and fisheries sector, having led the Fisheries Innovation Unit of the National Program for Innovation in Fisheries and Aquaculture (PNIPA). He has served as a senior consultant in technology watch, an innovation project formulator and advisor, and a lecturer at UNS. He is a member of the Peruvian College of Biologists and was recognized by the World Aquaculture Society (WAS) in 2016 for his contribution to aquaculture.