The increasing global demand for seafood products has led to a significant rise in aquaculture, the controlled cultivation of fish and seafood. However, limited space in coastal waters and environmental challenges have driven aquaculture expansion into deeper offshore marine sites.

This approach, known as offshore aquaculture, holds the potential to be a sustainable solution to meet the demand for seafood products. Nevertheless, to succeed in more hostile marine environments, expertise in offshore engineering is essential.

A scientific review published by researchers from Griffith University, The University of Queensland, the Blue Economy Cooperative Research Centre, the University of Tasmania, and DNV Offshore Classification Maritime Sector compiles design criteria for offshore fish farms under the following subtopics: design life, design environmental loads, combining environmental loads, and miscellaneous load conditions.

Engineering for Offshore Aquaculture

The relocation of fish farms to offshore locations is a significant step toward sustainability in farmed fish production. However, these facilities must contend with a harsher marine environment, which poses unique challenges. To design and analyze offshore aquaculture infrastructure, expertise in offshore engineering is necessary.

Design and Analysis in Offshore Aquaculture

This article reviews existing design and analysis guidelines provided by national and international authorities and maritime classification organizations that may be applicable to offshore fish farms. It focuses on the following subtopics:

- Design Life: The durability of offshore infrastructure is crucial for its long-term profitability and sustainability. Existing guidelines related to design life are analyzed.

- Design Environmental Loads: Offshore facilities must withstand extreme weather conditions and ocean forces. Guidelines on how to calculate and address environmental loads are reviewed.

- Combining Environmental Loads: The interaction of multiple environmental loads is a critical aspect of offshore infrastructure design. This article examines how these loads should be combined and assessed.

- Various Load Conditions: In addition to environmental loads, diverse load conditions, such as wave and current impacts, must be considered. Guidelines for addressing these situations are reviewed.

Global Performance Analysis

The article also focuses on procedures and methods for global performance analysis, based on practices used in neighboring industries such as offshore oil and gas production and wind energy. The following subtopics are discussed in detail:

- Hydrostatic Analysis: Techniques for evaluating the behavior of structures in water through hydrostatic analysis are examined.

- Hydrodynamic Analysis: The study of how structures interact with water forces and waves is fundamental for safety and efficiency. Methods and theories behind hydrodynamic analysis are presented.

- Mooring System Analysis: The mooring system is essential for maintaining the stability of offshore facilities. This article introduces analysis techniques and the underlying theory.

Design Standards and Technical Guidelines

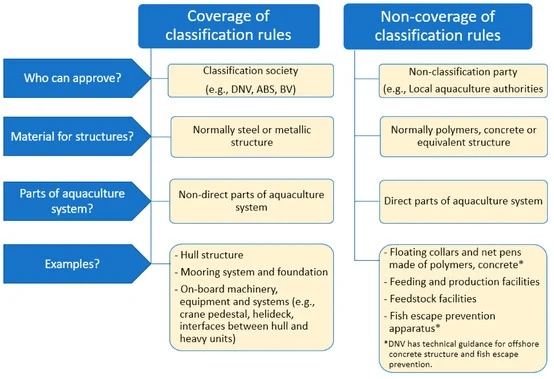

When designing a new product, engineers and designers must consider a set of criteria that can guide their design processes. Within the aquaculture industry, when developing the design of a new fish cage, client approval is necessary.

Among classification societies, the American Bureau of Shipping (ABS) and Det Norske Veritas (DNV) provide rules and certification standards for offshore fish farming facilities, including:

- ABS, Guide for building and classing, aquaculture installations.

- ABS-FPI, Rules for building and classing, floating production installations.

- ABS-OI, Rules for building and classing, facilities on offshore installations.

- ABS, Position mooring systems.

- DNV-RU-OU-0503, Rules for classification, offshore fish farming units and installations.

- DNV-ST-C502, Offshore concrete structures.

- DNV-OTG-24, Fish escape prevention from marine fish farms.

- DNV-OS-C101, Design of offshore steel structures, general—LRFD method.

- DNV-OS-C102, Offshore standard for structural design of offshore ships.

- DNV-OS-C103, Structural design of column stabilised units—LRFD method.

- DNV-OS-C106, Structural design of deep draught floating units—LRFD method.

- DNV-OS-C201, Offshore standard for structure design of offshore units—WSD method.

- DNV-RP-C205, Environmental conditions and environmental loads.

- DNV-RP-F205, Global performance analysis of deepwater floating structures.

- DNV-OS-E301, Offshore standard for position mooring.

Additionally, there are national and international standards such as:

- Norway Standard, NS 9415, Marine fish farms requirements for design, dimensioning, production, installation, and operation (inclusive Norway Standard, NS 3472, Steel Structures—Design rules).

- Marine Scotland, A technical standard for Scottish finfish aquaculture.

- ISO 16488:2015, Marine finfish farms—open net cage-design and operation.

Limitations and Precautions

The importance of recognizing limitations and precautions when using these design and analysis methods in the context of offshore aquaculture is emphasized, given that the environment is unique and presents specific challenges.

The study reports inconsistencies in different design guidelines, particularly regarding combinations of environmental loads and safety factors for evaluating moorings.

Furthermore, it is highlighted that the document did not include design criteria such as fatigue and risk assessments, which largely depend on the selection of construction materials and fish farming methods.

Conclusions

Providing this comprehensive information, along with commentary on its applicability, empowers engineers and designers to develop offshore aquaculture infrastructure with confidence.

“More efforts are needed to provide a unified guideline as well as a more rational design approach through direct analysis in the design of offshore fish pens to gain industry confidence regarding offshore farms,” conclude the researchers.

This represents a significant step toward a sustainable and secure future in seafood production, essential to address the growing demands of an ever-increasing global population.

The study was funded by the Blue Economy Cooperative Research Centre of Australia.

Reference (open access)

Chu, Y.-I.; Wang, C.-M.; Zhang, H.; Abdussamie, N.; Karampour, H.; Jeng, D.-S.; Baumeister, J.; Aland, P.A. Offshore Fish Farms: A Review of Standards and Guidelines for Design and Analysis. J. Mar. Sci. Eng. 2023, 11, 762. https://doi.org/10.3390/jmse11040762

Editor at the digital magazine AquaHoy. He holds a degree in Aquaculture Biology from the National University of Santa (UNS) and a Master’s degree in Science and Innovation Management from the Polytechnic University of Valencia, with postgraduate diplomas in Business Innovation and Innovation Management. He possesses extensive experience in the aquaculture and fisheries sector, having led the Fisheries Innovation Unit of the National Program for Innovation in Fisheries and Aquaculture (PNIPA). He has served as a senior consultant in technology watch, an innovation project formulator and advisor, and a lecturer at UNS. He is a member of the Peruvian College of Biologists and was recognized by the World Aquaculture Society (WAS) in 2016 for his contribution to aquaculture.