The aquaculture sector, a fundamental pillar for global food security, faces growing pressures: optimizing resources, minimizing environmental impact, and controlling diseases are daily challenges. In this scenario, a disruptive technology is emerging as a transformative solution: the digital twin (DT), a virtual and dynamic replica of a physical aquaculture system that promises to take farm management to a new level of efficiency and sustainability.

A recent scientific review article published in the journal Fishes by scientists from the Yellow Sea Fisheries Research Institute, of the Qingdao Marine Science and Technology Center of Dalian Ocean University, explores in depth the current state, opportunities, and challenges of applying this technology in aquaculture. Below, we break down its key findings to understand how this innovation could redefine the future of aquaculture production.

What exactly is a digital twin in aquaculture?

Imagine having an exact virtual copy of your production system: your tanks, recirculation systems, feeders, and even the biomass you are cultivating. Now, imagine that this copy is updated in real-time with data from sensors that measure everything happening in the physical system. That is, in essence, a digital twin.

This technology integrates physical models, sensor data, and operational history to create a digital map that reflects the entire lifecycle of the physical equipment. Its core is a virtual model that, fed with constant data, allows for real-time monitoring, simulations, optimizations, and predictive decision-making. In aquaculture, this translates into the ability to anticipate problems, automatically adjust parameters, and ensure that organisms grow under ideal conditions.

A digital twin system is composed of four key elements that work together:

- Sensors and IoT devices: They collect data from the physical environment (pH, dissolved oxygen, temperature, fish behavior, etc.).

- Data analysis and processing: Artificial intelligence (AI) and machine learning algorithms process the data to detect patterns, predict trends, and generate recommendations.

- Virtual models: Digital representations of the physical system (tanks, fish health models, feeding systems) that allow for risk-free scenario simulation.

- Control systems: They act on the physical environment based on the digital model’s decisions, for example, by activating an aerator or adjusting the feed ration.

Practical applications that are already transforming production

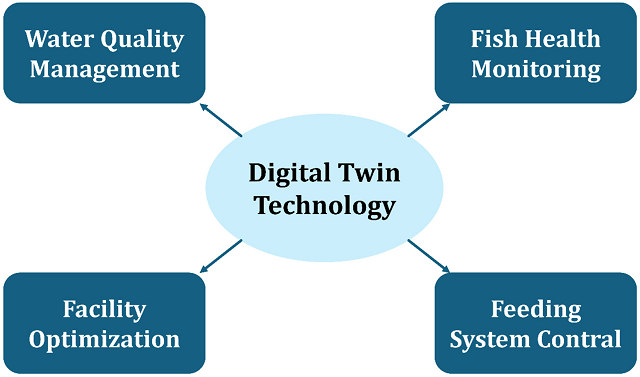

The true strength of digital twins lies in their practical applications. The study identifies four main areas where this technology offers competitive and sustainable advantages.

Real-time environmental monitoring and control

Water quality management is a cornerstone of aquaculture, but traditional manual sampling methods often lead to delays in decision-making. Digital twins allow for continuous monitoring of critical parameters like pH, temperature, dissolved oxygen, and ammonia. By combining this data with predictive models, the system can simulate how these factors interact and anticipate problems, allowing operators to adjust aeration or water circulation before the fish are affected.

Health monitoring and disease prevention

Diseases are one of the biggest economic risks in the sector. Instead of reacting to visible symptoms, digital twins offer a proactive approach. By tracking subtle changes in swimming patterns or feeding behavior, systems can detect early signs of stress or disease. Combining this data with water quality and historical trends, predictive models can forecast the probability of outbreaks, allowing for early interventions such as water adjustments or quarantine measures.

Facility optimization and simulation

Before building or modifying a facility, digital twins allow for the simulation of different designs to find the most efficient configuration. Using computational fluid dynamics (CFD) simulations, it is possible to optimize water flow in tanks to eliminate “dead zones” where waste accumulates and oxygen is low. This not only improves fish health but also optimizes the energy consumption of aeration and filtration systems, reducing operational costs.

Stay Always Informed

Join our communities to instantly receive the most important news, reports, and analysis from the aquaculture industry.

Precision feeding for maximum efficiency

Feed represents a significant portion of production costs. Precision feeding is one of the most impactful applications of digital twins. The process is a continuous optimization cycle:

- Real-time data collection: Sensors monitor fish activity, water temperature, and feed consumption.

- Predictive analysis: The model predicts the nutritional needs of the fish based on their size, activity, and environmental conditions.

- Automated adjustments: The feeding system automatically adjusts the quantity and frequency of the ration. If the fish are less active, it reduces the feed to minimize waste.

- Waste reduction: By dynamically adjusting the schedule, it ensures that the exact amount of feed is provided, improving the feed conversion ratio (FCR) and reducing water pollution from uneaten feed.

- Minimizing environmental footprint: Optimized feed management reduces the nutrient load in the water and energy consumption, making the operation more sustainable.

Challenges on the path to mass adoption

Despite its enormous potential, the implementation of digital twins in aquaculture is not without challenges. The study highlights four main barriers:

- Technical: The accuracy and reliability of sensors in harsh aquatic environments can be an issue, as well as the real-time synchronization of data from multiple sources.

- Data management: The massive volume of data generated requires an advanced computational infrastructure. Furthermore, the security and privacy of this sensitive operational data are crucial concerns.

- Economic and financial: The initial investment in sensors, software, and infrastructure can be prohibitive, especially for small and medium-sized producers. Maintenance and upgrade costs must also be considered.

- Integration and interoperability: Integrating this new technology with the legacy systems and equipment of many farms can be complex and requires extensive staff training.

Conclusion: A predictive future for aquaculture

Digital twin technology represents a paradigm shift for aquaculture, moving from reactive to predictive and proactive management. By providing precise control, optimizing resource use, and enabling early interventions, this innovation offers tangible improvements in productivity, profitability, and environmental sustainability.

Although challenges such as high initial costs and technical complexity persist, its value in improving economic viability and environmental management is undeniable. As the industry moves towards smart aquaculture, the widespread adoption of digital twins will be fundamental to meeting the growing global demand for seafood sustainably and profitably.

Reference (open access)

Chen, J., Xu, Y., Li, H., Zhao, X., Su, Y., Qi, C., Qu, K., & Cui, Z. (2025). The Application of Digital Twin Technology in the Development of Intelligent Aquaculture: Status and Opportunities. Fishes, 10(8), 363. https://doi.org/10.3390/fishes10080363

Editor at the digital magazine AquaHoy. He holds a degree in Aquaculture Biology from the National University of Santa (UNS) and a Master’s degree in Science and Innovation Management from the Polytechnic University of Valencia, with postgraduate diplomas in Business Innovation and Innovation Management. He possesses extensive experience in the aquaculture and fisheries sector, having led the Fisheries Innovation Unit of the National Program for Innovation in Fisheries and Aquaculture (PNIPA). He has served as a senior consultant in technology watch, an innovation project formulator and advisor, and a lecturer at UNS. He is a member of the Peruvian College of Biologists and was recognized by the World Aquaculture Society (WAS) in 2016 for his contribution to aquaculture.