The rise of Industry 4.0, a revolution driven by digitalization and smart technologies, is transforming industries worldwide. In the dynamic world of aquaculture, Digital Twin technology is emerging as a powerful tool to unlock new levels of efficiency, sustainability, and profitability.

Imagine a virtual replica of your fish farm, constantly collecting data, predicting problems, and optimizing operations in real-time. This is the exciting potential of Digital Twin technology, and it is poised to transform the aquaculture industry as we know it.

Scientists from NTNU, SINTEF Ocean, KU Leuven, and the Hellenic Centre of Marine Research published a scientific review discussing the potential of Digital Twin technology as a key component to kickstart Industry 4.0 in aquaculture and outline a path forward to achieve this goal.

What is a digital twin?

So, what exactly is a digital twin? Think of it as a living, breathing model of your fish farm, built in the digital world. It combines real-time sensor data with advanced mathematical models to create a dynamic representation of your entire operation. This includes everything from water quality and oxygen levels to fish growth and behavior, even the movements of robots in the cage!

But why is this so important for aquaculture?

The traditional approach to fish farming often relies on intuition and experience, leading to inefficiencies and potential risks. Digital twins, however, offer a data-driven predictive approach. They can:

- Identify problems before they occur: Imagine receiving an alert about a potential drop in oxygen levels before it harms your fish.

- Optimize feeding strategies: Adjust feeding quantities and schedules based on individual fish growth and environmental conditions.

- Minimize environmental impact: Reduce water waste and nutrient discharge through precise control of aquaculture operations.

- Improve fish welfare: Monitor stress levels and adjust conditions to ensure optimal health.

Case Studies

Although still in its early stages, the basic components of digital twins in aquaculture are quickly coming together. Advances in sensor technology, artificial intelligence, and computational modeling are paving the way for powerful and practical applications.

This article explored three specific use cases:

- Oxygen monitoring in sea cages: Predict and prevent harmful oxygen fluctuations, protecting your fish and improving farm efficiency.

- Fish growth optimization: Track individual fish growth patterns and adjust feeding strategies for maximum performance and resource utilization.

- Robotics in cage and vehicle operations: Optimize robot and underwater vehicle movements for tasks such as cleaning and data collection, improving efficiency and reducing manual labor.

The case studies described in the scientific article add to the experiences being conducted in the Tasmanian salmon industry and rainbow trout farming.

How to implement digital twins in aquaculture?

The potential of digital twins in aquaculture is enormous. They offer a vision of a future where farms will be smarter, more sustainable, and more profitable. By adopting this technology, aquaculture can tackle the challenges of Industry 4.0 and continue to provide a vital source of protein for a growing global population.

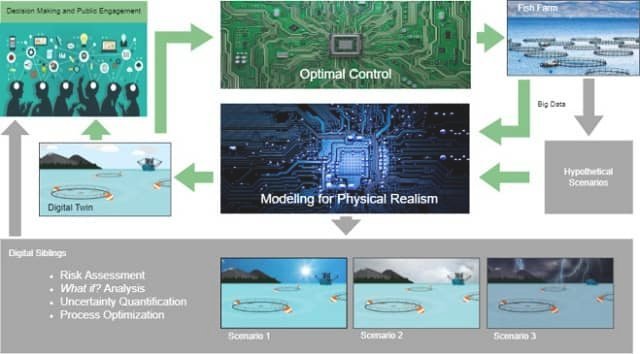

The article delves into the fundamental components of an aquaculture digital twin, exploring:

- Key components: Sensor networks, data pipelines, advanced models, and user interfaces for interactive analysis.

- Building process: Integrate existing data, build robust models, and ensure learning and continuous improvement.

- Capability levels: From basic monitoring to real-time optimization and predictive maintenance.

Roadmap to Aquaculture 4.0

While digital twins are still in their early stages in aquaculture, the potential is undeniable. This is how we can pave the way to Aquaculture 4.0:

- Develop robust sensor technology: Collect reliable, real-time data from various aspects of the farm.

- Refine mathematical models: Improve accuracy and incorporate biological complexities.

- Create user-friendly platforms: Make Digital Twins accessible and intuitive for aquaculturists.

- Focus on specific applications: Start with high-impact areas such as disease prevention and resource optimization.

Conclusion

By embracing digital twins, aquaculture can leap into a new era of efficiency, sustainability, and profitability. This technology is not just about replicating the farm; it’s about transforming it into a data-driven intelligent system that ensures a better future for both the fish and our planet.

This is just the beginning of the journey. As technology continues to evolve, so will the capabilities of digital twins. The future of aquaculture is bright and data-driven, fueled by intelligence and a drive for innovation.

Further research and development are crucial to overcome challenges such as data security, integration, and profitability. Collaboration among scientists, engineers, and industry stakeholders is key to unlocking the full potential of digital twins in aquaculture.

Contact

Martin Føre

Department of Engineering Cybernetics, NTNU, Trondheim, Norway

Email: Martin.fore@ntnu.no

Reference (open access)

Føre, M., Alver, M. O., Alfredsen, J. A., Rasheed, A., Hukkelås, T., Bjelland, H. V., … & Papandroulakis, N. (2024). Digital Twins in intensive aquaculture—Challenges, opportunities and future prospects. Computers and Electronics in Agriculture, 218, 108676.