Callum Russell, University of the West of Scotland

Microalgae have been used by the Chinese for medicinal and nutritional purposes for thousands of years in the belief they could cure almost any health condition. The idea that microalgae have extraordinary healing powers isn’t as far-fetched as some might think. Though the ancient Chinese believed the microalgae was responsible for health-improving benefits, we now know that it was in fact the biochemical compounds produced by these microscopic creatures that provided the “magic”.

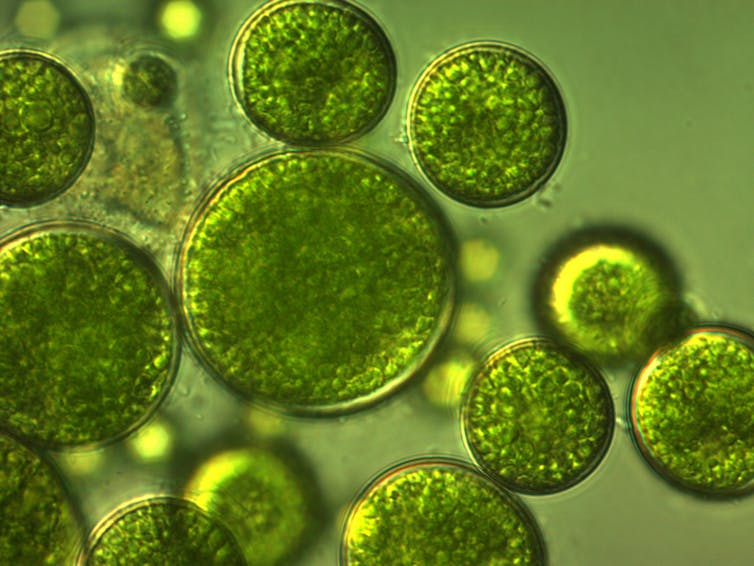

There are approximately 100,000 species of microalgae, each with their own distinct set of properties. This diversity allows microalgae to flourish in almost every environment on Earth. Mostly they exist in aquatic habitats such as fresh or wastewater, but they have been found in moist soil – and even snowbanks too.

Microalgae are usually described as being green, and this is true for species such as B. braunii and C. vulgaris. But there are other species, such as C. officinalis, which is red or F. spiralis, which is brown. Each classification produces different types or quantities of biochemical compounds, making some more useful for certain applications than others.

Over the past few decades research has demonstrated the huge potential of microalgae, especially in the production of biofuel – fuel that is created from plant material or animal waste. I wanted to review this research to provide a framework to establish the most suitable microalgae species for large-scale biofuel production that can ultimately rival oil and gas giants and reduce our reliance on fossil fuels.

The magic of micoalgae

Microalgae have a unique ability to convert sunlight and carbon dioxide into a wide range of biochemical compounds. Despite being classed as animals, they metabolise the same way as plants, producing oxygen to replenish what we humans consume. This cycle acts as a carbon capture system, whereby harmful CO2 in the atmosphere is converted to useful oxygen. Microalgae also produce a wide range of other compounds found inside the cells, and these are what make microalgae so good at combating the effects of global warming.

Generally, the products from microalgae can be grouped into three classes: proteins, carbohydrates and lipids (fats). But research has found that there are several other high-value biochemical compounds that have significant applications in a wide range of different industries. For example, microalgae produce compounds known as carotenoids, more commonly known as dyes or pigments. These compounds are responsible for giving salmon its pink colour, as the food they eat contains high quantities of carotenoids.

Another high-value class of compounds are polyunsaturated fatty acids (PUFA). These compounds are part of the lipid family and play a vital role in supplying the cells with energy. Microalgae have been deemed one of the richest sources of these compounds, which help treat the effects of diabetes and arthritis.

Stay Always Informed

Join our communities to instantly receive the most important news, reports, and analysis from the aquaculture industry.

But how is it possible for these organisms to produce oil that can be used in cars? The petrol and diesel currently used is derived from crude oil that was formed millions of years ago from dead sea creatures. But modern biofuel is produced from living organisms on a real-time basis.

How biofuel is produced

Biofuel made from microalgae is currently one of the most promising fossil fuel alternatives to sustain the world’s energy demand. This is no easy task, especially having to compete with a highly profitable industry that has been established for more than a century. But unlike oil, which is non-renewable, biofuel is a renewable and sustainable source of fuel. Unfortunately, the economics of biofuel can’t yet compete with traditional fossil fuels. It all boils down to the bottom line, and currently the scale-up technology required isn’t here yet.

Microalgae don’t directly produce biofuel – they produce lipids (fats). To make biofuel these fats must be converted through a process known as transesterification. The process involves removing as much water as possible, known as dewatering, but this requires significant amounts of energy, resulting in high operating costs. As a result, the overall process becomes too expensive to compete with the oil and gas industry, despite its positive environmental impact.

Economics aside, the future for microalgae cultivation and lipid extraction is extremely promising. The development of hybrid technologies will accelerate the global shift to reducing our reliance on fossil fuels. These include cell factories that use gold nanoparticles – subatomic particles similar to atoms that form the building blocks of physical matter – to increase production rates and increase efficiencies.

Another potential solution is a process known as “milking”. Traditional cultivation methods for microalgae mean they are destroyed after the cultivation period has ended, which limits the full potential of what each cell can offer. Just like milking a cow, the process can be repeated without killing the cow, and the same goes for microalgae. By repeatedly removing high-value compounds from the same culture of microalgae, the high production cost issues can be removed, resulting in a sustainable and scalable process for the future.

This would result in biofuel becoming cost competitive with current fossil fuels, helping to accelerate the shift towards alternative energy sources. Unfortunately, the prospect of competitive biofuel production has some way to go before it can rival fossil fuel prices and quantities. But these developing technologies have the potential to speed up the transition needed to help the world reach its 2050 emissions targets.![]()

Callum Russell, Chemical Engineering PhD, University of the West of Scotland

This article is republished from The Conversation under a Creative Commons license. Read the original article.

Editor at the digital magazine AquaHoy. He holds a degree in Aquaculture Biology from the National University of Santa (UNS) and a Master’s degree in Science and Innovation Management from the Polytechnic University of Valencia, with postgraduate diplomas in Business Innovation and Innovation Management. He possesses extensive experience in the aquaculture and fisheries sector, having led the Fisheries Innovation Unit of the National Program for Innovation in Fisheries and Aquaculture (PNIPA). He has served as a senior consultant in technology watch, an innovation project formulator and advisor, and a lecturer at UNS. He is a member of the Peruvian College of Biologists and was recognized by the World Aquaculture Society (WAS) in 2016 for his contribution to aquaculture.