In a world urgently seeking alternatives to fossil fuels and more sustainable protein sources, microalgae are emerging as a multifaceted solution. These microscopic organisms, with their incredible photosynthetic efficiency, form the basis of a revolutionary concept: the microalgae biorefinery. Just as an oil refinery processes crude oil to obtain different fuels and materials, a biorefinery uses algal biomass as a raw material to generate a diversity of valuable bioproducts.

A recent systematic review study published by researchers from Chengdu Normal University, the University of Sargodha, Emerson University, the University of the Punjab, and Bahauddin Zakariya University has conducted an in-depth analysis of the entire value chain of these “green factories.” The study evaluates technological advancements, economic barriers, and innovation pathways that could bring this technology from the laboratory to the market. For aquaculture professionals, the findings are particularly relevant, positioning microalgae not only as a source of clean energy but also as a fundamental pillar for the future of aquaculture feed.

- 1 Key takeaways

- 2 What exactly is a microalgae biorefinery?

- 3 From cultivation to product: The production process

- 4 Beyond biofuel: A factory for high-value products

- 5 Environmental benefits that make a difference

- 6 Current challenges: What hinders commercial deployment?

- 7 Conclusion: A promising but demanding path

- 8 Entradas relacionadas:

Key takeaways

- Microalgae biorefineries are integrated systems that transform algal biomass into a wide range of products, from biofuels to animal feed and nutraceuticals.

- Microalgae offer key advantages over traditional crops: high growth rates, no competition for arable land, and the ability to grow in wastewater or saline water.

- One of the highest-value products for the sector is protein-rich algal meal, a sustainable alternative to fishmeal in aquaculture feed.

- Despite its potential, large-scale commercialization faces challenges such as high operating costs, significant energy consumption during harvesting, and the need to optimize conversion efficiency.

- Integrating microalgae cultivation with wastewater treatment and industrial CO2 capture is crucial for improving its economic and environmental viability.

What exactly is a microalgae biorefinery?

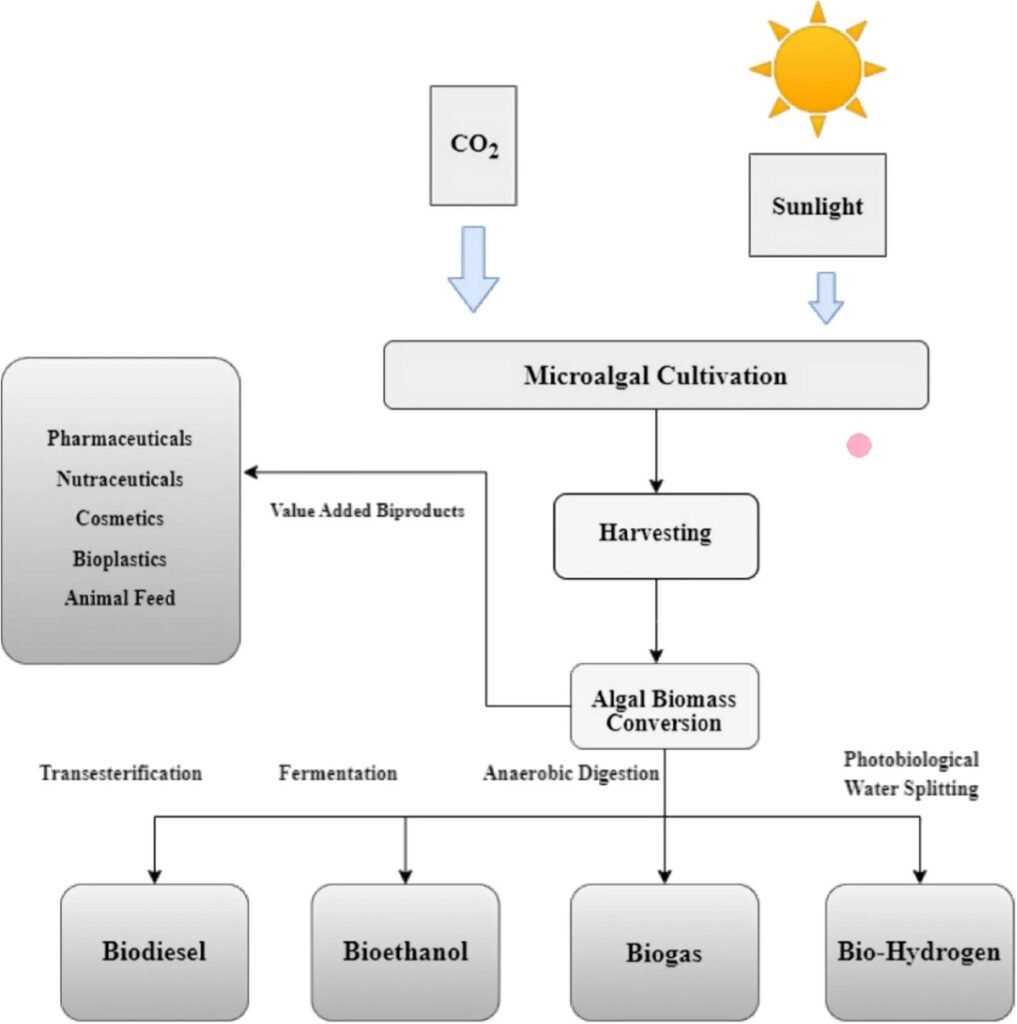

The biorefinery concept is based on maximum resource efficiency, seeking to utilize every component of the biomass to minimize waste and maximize value. Microalgae are an ideal feedstock for this approach due to their rich biochemical composition, which includes lipids, proteins, carbohydrates, vitamins, and minerals.

Within a biorefinery, this biomass can be fractionated to produce:

- Lipids: for the production of biodiesel.

- Carbohydrates: to produce bioethanol through fermentation.

- Proteins: for formulating animal feed, including for aquaculture, or nutraceuticals for humans.

- Residual Biomass: to generate biogas via anaerobic digestion or to be used as a fertilizer.

This integrated approach, aligned with the principles of the circular economy, allows nutrients and water used in the process to be recycled, significantly reducing the environmental impact.

From cultivation to product: The production process

The success of a biorefinery depends on a chain of optimized processes, from initial cultivation to the final extraction of products.

Cultivation systems: Open ponds vs. photobioreactors

Algal biomass production is primarily carried out in two types of systems:

- Open ponds: These are low-cost, low-energy systems where algae grow in large outdoor ponds. However, they are vulnerable to contamination, evaporation, and climate fluctuations, which affect production consistency.

- Photobioreactors (PBRs): These are closed, transparent systems that offer complete control over cultivation conditions (light, CO2, nutrients). This results in higher productivity and a lower risk of contamination, but their capital expenditure (CAPEX) is significantly higher.

The choice of system involves a trade-off between cost and performance, and hybrid designs are currently being researched to combine the best of both worlds.

Harvesting and drying: An energy bottleneck

Due to their microscopic size, separating algae from water is an energy-intensive process, accounting for up to 25-30% of the plant’s total energy consumption. Methods like centrifugation are efficient but costly in terms of electricity. Alternatives such as flocculation (clumping the cells together) reduce energy expenditure but may introduce chemical contaminants.

Stay Always Informed

Join our communities to instantly receive the most important news, reports, and analysis from the aquaculture industry.

Subsequently, drying the biomass to achieve over 95% dry matter also requires a large amount of thermal energy, which inflates operating costs (OPEX) and remains one of the biggest challenges to the process’s economic viability.

Beyond biofuel: A factory for high-value products

While biofuels are a significant driver, the economic viability of biorefineries often depends on the co-production of higher-value products.

Animal feed: The great opportunity for aquaculture

Microalgae like Spirulina and Chlorella are renowned for their high content of quality protein, essential amino acids, vitamins, and minerals. This makes them an ideal ingredient for animal feed.

For aquaculture, algal meal represents a sustainable alternative to fishmeal and fish oil, whose dependency contributes to overfishing and environmental degradation. Replacing traditional ingredients with algal proteins not only reduces the sector’s ecological footprint but can also improve the growth rates and immune response of farmed animals. Furthermore, the cultivation of these microalgae does not compete with traditional agriculture, as it can be done on non-arable land using wastewater as a nutrient source.

Other valuable products

- Nutraceuticals: Algae are a primary and sustainable source of omega-3 fatty acids (EPA and DHA), a vegan alternative to fish oil with proven benefits for human health.

- Cosmetics: Algae extracts contain antioxidants, polysaccharides, and proteins that offer skincare benefits, such as anti-aging, moisturizing, and UV-protection effects.

- Bioplastics: Certain microalgae strains can produce biodegradable polyesters like PHAs (polyhydroxyalkanoates), which offer an ecological alternative to petroleum-derived plastics.

Environmental benefits that make a difference

Algae biorefineries offer not only valuable products but also crucial ecosystem services.

- CO2 Mitigation: Microalgae are exceptional carbon bio-fixers. It is estimated that for every ton of dry algal biomass produced, approximately 1.8 tons of CO2 are captured. Integrating cultivation with industrial emissions (e.g., from power plants) allows for converting a pollutant into a valuable resource.

- Wastewater Treatment: Cultivating microalgae in wastewater is an effective strategy for removing nutrients like nitrogen and phosphorus, treating the effluent while generating biomass at no fertilizer cost.

- Lower Water and Land Footprint: Unlike first-generation biofuel crops (corn, soy), algae can be grown on non-agricultural land and in saline, brackish, or wastewater, eliminating competition for freshwater and fertile land resources.

Current challenges: What hinders commercial deployment?

Despite their enormous potential, the transition of algae biorefineries to a commercial reality remains a path fraught with obstacles. The study identifies several critical barriers:

- Production Costs: The estimated cost of algal biodiesel remains significantly higher ($6-8/gallon) than petroleum diesel, primarily due to the high costs of nutrients, energy for harvesting and drying, and still-suboptimal biomass yields under real-world conditions.

- Energy Consumption: The energy balance remains a weak point. The processes of harvesting, drying, and biomass extraction consume a considerable amount of energy, which can diminish the net environmental benefits if renewable sources are not used.

- Scalability: Technologies that perform well at a laboratory scale, such as certain extraction techniques or genetic engineering of strains, often face difficulties in being implemented cost-effectively at an industrial scale.

Conclusion: A promising but demanding path

Microalgae biorefineries represent a transformative platform for the future bioeconomy. They offer a pathway to produce renewable energy, sustainable food, and high-value bioproducts, all while mitigating climate change and treating effluents.

For the aquaculture sector, the development of this technology is a strategic opportunity to advance towards greater sustainability and reduce dependence on finite marine resources. However, the road to commercial viability is demanding. Continuous research, innovation in low-energy technologies, and supportive regulatory frameworks are needed to overcome the current economic and technological bottlenecks. Only through a concerted effort among academia, industry, and governments can the immense potential of microalgae be fully realized.

Contact

Abdur Rehim

Department of Soil Science, Faculty of Agricultural Sciences and Technology, Bahauddin Zakariya University

Multan, 60800, Pakistan

Email: abdur.rehim@bzu.edu.pk

Reference (open access)

Geng, Y., Shaukat, A., Azhar, W. et al. Microalgal biorefineries: a systematic review of technological trade-offs and innovation pathways. Biotechnol. Biofuels Bioprod. 18, 93 (2025). https://doi.org/10.1186/s13068-025-02694-7

Editor at the digital magazine AquaHoy. He holds a degree in Aquaculture Biology from the National University of Santa (UNS) and a Master’s degree in Science and Innovation Management from the Polytechnic University of Valencia, with postgraduate diplomas in Business Innovation and Innovation Management. He possesses extensive experience in the aquaculture and fisheries sector, having led the Fisheries Innovation Unit of the National Program for Innovation in Fisheries and Aquaculture (PNIPA). He has served as a senior consultant in technology watch, an innovation project formulator and advisor, and a lecturer at UNS. He is a member of the Peruvian College of Biologists and was recognized by the World Aquaculture Society (WAS) in 2016 for his contribution to aquaculture.