In the ongoing pursuit of sustainable and circular food production systems, aquaponics has emerged as a brilliant solution by merging fish farming with hydroponic vegetable cultivation. However, even the most efficient systems face the challenge of maximizing every gram of nutrient. This is where a disruptive innovation comes into play: Algaeponics.

“Traditionally, aquaponics has always consisted of fish and plants,” states Jemuel S. Doctolero, a Fulbright scholar from the Philippines and lead researcher of a pioneering study published in the journal Aquaculture. “In our project, we introduced a secondary biomass: microalgae. Microalgae offer a multitude of benefits; while not a traditional food source, they have commercial applications in nutraceuticals, pharmaceuticals, cosmetics, animal feed, biogas, and biofuels.”

This approach seeks not only to produce more but to produce more intelligently, transforming nitrogenous fish waste into high-value-added products.

Key Highlights

- Nutritional Control: Fish stocking density acts as a biological “dial” that allows for the programming of whether the algae will be protein-rich or lipid-heavy.

- Triple Yield: High densities (30 to 40 kg m-3) simultaneously maximize fish biomass, lettuce harvest, and microalgae production.

- The Rise of ‘Algaeponics’: Integrating Chlorella vulgaris enables the recovery of nutrients that would otherwise be lost, thereby diversifying the farmer’s revenue streams.

- Global Impact: This hybrid model bolsters local food security and the circular economy by repurposing water and organic waste.

Designing the Hybrid Ecosystem

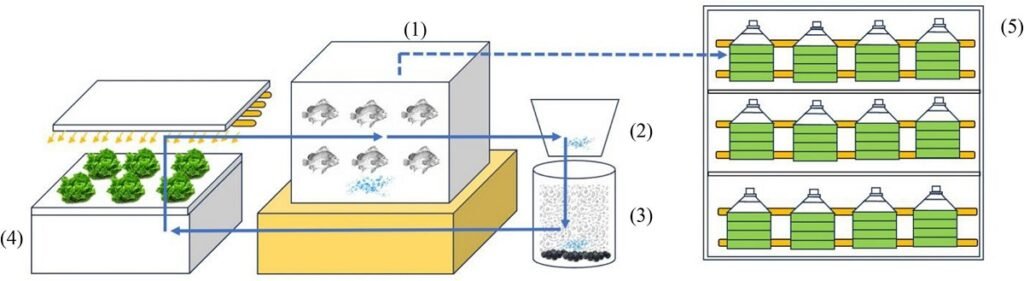

For Doctolero’s research, he and his colleagues from the Department of Forestry and Natural Resources at Purdue University established twelve independent aquaponic systems. They utilized Nile tilapia (Oreochromis niloticus) and lettuce (Lactuca sativa cv. Muir), two common staples in such facilities.

The team tested four fish stocking densities: 10, 20, 30, and 40 kg m-3. Once the system stabilized and nitrates began to accumulate, they introduced the new biological component: Chlorella vulgaris, a green microalga renowned for its robustness and nutritional profile.

The system was designed as a partially decoupled model. While the fish and lettuce shared a constant recirculation loop, the algae were cultivated independently in 11.36-liter containers, receiving fish tank effluent one hour after feeding—the period when excreted ammonia levels are at their peak.

“I spent a significant amount of time designing the setup,” Doctolero admits. “It took approximately two months to construct the system, but the actual experiment lasted five weeks.”

The Ripple Effect of Fish Density

The research revealed that the number of fish in the tank does not merely affect tilapia growth; it triggers a chain reaction that alters the entire chemistry of the system.

Maximum Productivity at High Densities

The researchers found that higher initial stocking densities (30 to 40 kg m-3) provided distinct advantages. Increased density allowed both plants and algae to be more productive overall:

Stay Always Informed

Join our communities to instantly receive the most important news, reports, and analysis from the aquaculture industry.

- Algal Biomass: The 40 kg m-3 treatment generated significantly more C. vulgaris biomass than the low-density treatments.

- Lettuce Yield: Lettuce yield, in both fresh and dry weight, increased linearly with fish density.

- Tilapia Growth: Surprisingly, increasing density up to 40 kg m-3 did not compromise fish growth or survival, suggesting the system remained within healthy water quality parameters.

Algae as a Nutritional “Chameleon”

The most fascinating discovery was the microalgae’s ability to shift its chemical composition based on nutrient availability.

- Super-Protein Mode: Higher fish densities resulted in higher nutrient concentrations, prompting the algae to produce more crude protein and a more favorable essential amino acid profile, particularly lysine and methionine. This makes them ideal for nutritional supplements or aquaculture feed.

- Biofuel Mode: Conversely, lower fish density induced nutritional stress (nitrogen limitation), which triggered the accumulation of crude lipids and fatty acids such as stearic and oleic acid. These components are essential for biogas and biodiesel production.

“This means that aquaponic practitioners could stock tanks with more or fewer fish depending on their end goal.”

Deep Science: Why Do Algae Change?

The study delves into the metabolic pathways of C. vulgaris. When nitrogen is abundant (high fish density), the algae activate the GS-GOGAT pathway, which converts ammonia directly into amino acids like glutamine and glutamate—the building blocks of protein.

However, when nitrogen is scarce (low density), the alga halts its cell division and redirects the carbon flow from photosynthesis toward energy storage in the form of fats. It is a survival mechanism: the alga “fattens up” while waiting for better conditions.

The Future: Biofilms and Food Security

Despite the success, the current system employs centrifuges to harvest the algae, a process that is both energy-intensive and costly. Doctolero is already working on the next phase.

In the current setup, the microalgae were suspended in the water, but Doctolero is now investigating algae cultivation on a biofilm surface. This would simplify harvesting: farmers could simply scrape them off, eliminating the need for expensive centrifuges.

“If we can produce fish and plants locally with a small setup, it can help address food insecurity,” the researcher states. “And it has an environmental benefit, as it reuses water rather than discharging it into the environment.”

Conclusion: A Real-World Model

The study concludes that densities of 30 to 40 kg m-3 are most advisable for optimizing fish growth, plant biomass, and protein-rich algae production. However, the system’s flexibility is its greatest strength: it allows producers to diversify their income and adapt to market demands, whether by selling tilapia, gourmet lettuce, or algal biomass for the cosmetic or energy industries.

“Ultimately, our work demonstrates that algae can be effectively integrated into aquaponics to increase production value while enhancing nutrient recovery,” Doctolero concludes.

Contact

Jemuel S. Doctolero

Department of Forestry and Natural Resources, Purdue University

West Lafayette, IN, USA.

Department of Aquaculture, College of Fisheries, Central Luzon State University

Science City of Muñoz, Nueva Ecija, Philippines

Email: jdoctole@purdue.edu

Reference

Doctolero, J. S., Saha, J., Rice, T. A., Hussain, A. S., & Brown, P. B. (2026). Fish stocking density impacts nutritional composition of algae produced in a decoupled aquaponic system. Aquaculture, 612, 743277. https://doi.org/10.1016/j.aquaculture.2025.743277

Editor at the digital magazine AquaHoy. He holds a degree in Aquaculture Biology from the National University of Santa (UNS) and a Master’s degree in Science and Innovation Management from the Polytechnic University of Valencia, with postgraduate diplomas in Business Innovation and Innovation Management. He possesses extensive experience in the aquaculture and fisheries sector, having led the Fisheries Innovation Unit of the National Program for Innovation in Fisheries and Aquaculture (PNIPA). He has served as a senior consultant in technology watch, an innovation project formulator and advisor, and a lecturer at UNS. He is a member of the Peruvian College of Biologists and was recognized by the World Aquaculture Society (WAS) in 2016 for his contribution to aquaculture.