Industrialized shrimp farming faces a modern paradox: the need to intensify production to meet global demand clashes head-on with resource constraints and strict environmental regulations. For years, the prevailing strategy in Asia and Latin America has been to increase stocking density under the assumption that “more shrimp equals more profit.” However, scientific evidence suggests that without adequate technological safeguards, this practice leads to production crises and environmental issues.

A recent study published in the journal Aquaculture, conducted by researchers from the Ocean University of China and the GEOMAR Helmholtz Centre for Ocean Research Kiel (Germany), offers a new perspective on this challenge. Using an advanced ecosystem model, scientists have quantified the actual “carrying capacity” of industrial Litopenaeus vannamei systems and evaluated how different management practices impact both the producer’s bottom line and water quality.

- 1 Key Findings of the Study

- 2 The Challenge of Defining Carrying Capacity

- 3 Current Diagnosis: Are We Farming Too Many Shrimp?

- 4 Strategy Comparison: Seeking Sustainable Profitability

- 5 The Importance of Energy Budgets and Nutrients

- 6 Implications for the Future of Shrimp Farming

- 7 Conclusion

- 8 Entradas relacionadas:

Key Findings of the Study

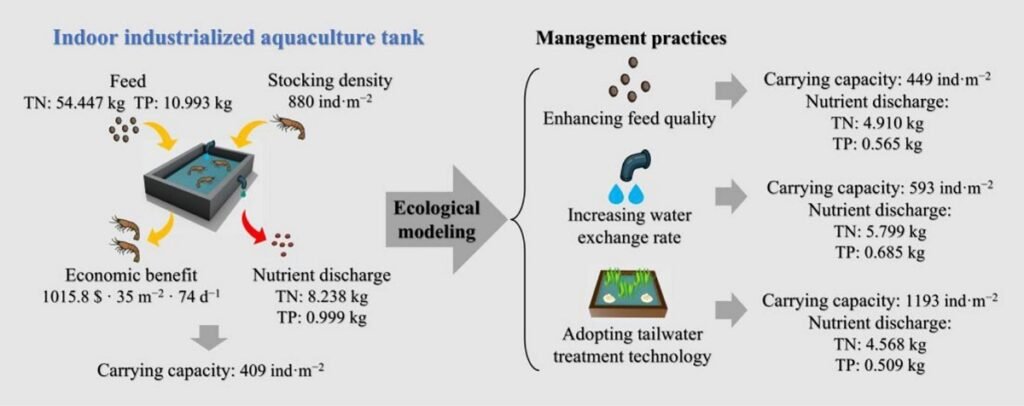

- Current Overload: Stocking densities of 880 ind/m² exceed the system’s environmental carrying capacity if effluents remain untreated.

- Economic Dilemma: Reducing density to meet environmental standards without updating technology cuts profitability by 71.5%.

- The Technological Solution: Implementing wastewater treatment technology proves to be the most effective strategy.

- Optimized Results: Effluent treatment allows for a density increase to 1,193 ind/m² and boosts economic profit by 33.5%.

The Challenge of Defining Carrying Capacity

“Carrying capacity” is traditionally defined as the maximum biomass a system can support without causing adverse environmental impacts. In indoor industrialized aquaculture systems, this concept is critical due to nutrient accumulation. Excess nitrogen and phosphorus, derived from uneaten feed and shrimp excretion, can deteriorate water quality and violate discharge regulations.

To address this, the research team developed an integrated ecosystem model combining a Dynamic Energy Budget (DEB) model—which simulates individual shrimp growth and metabolism—with a model of biogeochemical nitrogen and phosphorus cycles within the tanks. The study was validated with real-world data from an industrial farm in Dongying, China, ensuring the simulations faithfully reflected operational reality.

Current Diagnosis: Are We Farming Too Many Shrimp?

Initial analysis revealed a worrying reality for producers under strict regulations. In the current scenario (880 ind/m²), concentrations of Total Nitrogen (TN) and Total Phosphorus (TP) in discharge water exceed permitted thresholds (TN < 6 g/m³ and TP < 1 g/m³).

The model calculated that to meet standards without implementing new technologies, density would need to be drastically reduced to 409 ind/m². While this solves the environmental problem, the financial impact is devastating: production yield would drop by 53.5%, and economic profit would plummet by 71.5%. This demonstrates that simply reducing farming intensity is not a viable solution for economic sustainability.

Strategy Comparison: Seeking Sustainable Profitability

The researchers simulated three strategies to improve carrying capacity. Here is a breakdown of what works and what doesn’t:

Improving Feed Quality (Scenario B)

The use of higher quality feed was simulated, reducing the Feed Conversion Ratio (FCR) from 2.0 to 1.6.

- Result: Carrying capacity increased slightly to 449 ind/m².

- Impact: Economic profit grew by only 3.2%. The higher unit cost of premium feed limits net gains.

Increasing Water Exchange (Scenario C)

The water exchange rate was increased by 20% (rising from 40-50% to 60% daily).

Stay Always Informed

Join our communities to instantly receive the most important news, reports, and analysis from the aquaculture industry.

- Result: Carrying capacity rose to 593 ind/m².

- Impact: Although this dilutes pollutants, it significantly increases total nutrient discharge into the environment and raises water and energy consumption.

Implementing Effluent Treatment (Scenario E)

This was the winning strategy. The simulation incorporated technologies capable of removing 60% of nitrogen and phosphorus from wastewater.

- Result: Carrying capacity soared to 1,193 ind/m².

- Economic Impact: It enables increased density, achieving a 33.5% increase in economic profit.

- Environmental Benefit: Despite the higher biomass, Nitrogen and Phosphorus discharge was reduced by nearly 50%, using 26.2% less water per unit of production.

The Importance of Energy Budgets and Nutrients

A highlight of this research is the use of the DEB model. The study details that feed is the dominant source of nutrients, contributing 98.05% of the nitrogen and 99.23% of the phosphorus entering the system.

However, a large portion of these nutrients does not convert into biomass. Residual feed accounts for 43.70% of nitrogen output, underscoring that precise feed management remains critical. The model showed an accuracy of R² = 0.98, validating its utility as a predictive tool.

Implications for the Future of Shrimp Farming

This study confirms a historical lesson: intensification without technological support is a recipe for failure. For L. vannamei producers, investing in tailwater treatment systems is not an “expense,” but a strategic investment that enables higher densities and financial returns.

The model developed by Jiang, Dong, Wang, and their team provides a solid theoretical foundation and proves it is possible to align production goals with ecological conservation, moving toward true “sustainable intensification.”

Conclusion

The path to a more profitable and green industrial aquaculture does not necessarily lie in reducing production, but in managing it better. Carrying capacity is not a fixed number; it depends on the applied technology. By adopting effluent treatment, producers can break current density barriers, maximizing their profits while protecting water bodies.

Contact

Fang Wang

Engineering Research Center of Mariculture, Ministry of Education, Ocean University of China

5 Yushan Road, Qingdao, Shandong 266003, China.

Email: wangfang249@ouc.edu.cn

Reference

Jiang, K., Jiang, T., Dong, S., & Wang, F. (2026). Assessment of carrying capacity and management practices for Litopenaeus vannamei industrialized aquaculture based on an ecosystem model. Aquaculture, 613, 743453. https://doi.org/10.1016/j.aquaculture.2025.743453

Editor at the digital magazine AquaHoy. He holds a degree in Aquaculture Biology from the National University of Santa (UNS) and a Master’s degree in Science and Innovation Management from the Polytechnic University of Valencia, with postgraduate diplomas in Business Innovation and Innovation Management. He possesses extensive experience in the aquaculture and fisheries sector, having led the Fisheries Innovation Unit of the National Program for Innovation in Fisheries and Aquaculture (PNIPA). He has served as a senior consultant in technology watch, an innovation project formulator and advisor, and a lecturer at UNS. He is a member of the Peruvian College of Biologists and was recognized by the World Aquaculture Society (WAS) in 2016 for his contribution to aquaculture.