Aquaculture is undergoing a fundamental paradigm shift: the transition from traditional, empirical methods toward highly technified, data-driven systems. This new approach, termed “Precision Fish Farming” (PFF) or Aquaculture 5.0, promises to revolutionize the production of aquatic foods.

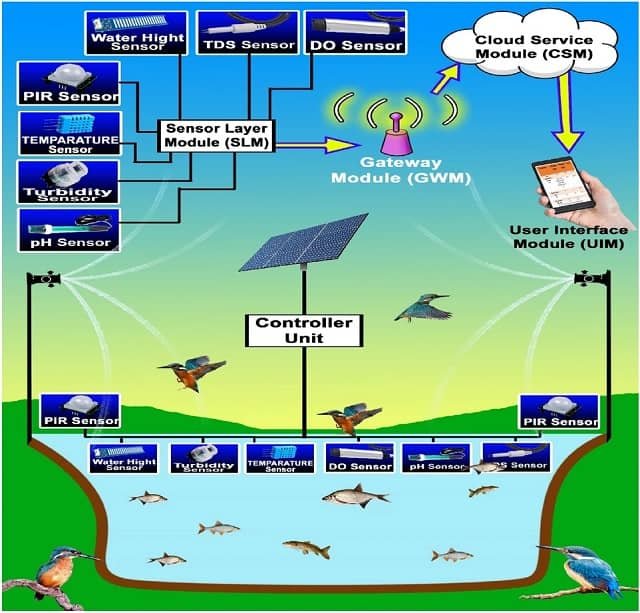

According to a recent review by Edo D’Agaro of the Department of Agricultural, Food, Environmental, and Animal Sciences at the University of Udine (Italy), integrating sensors, Artificial Intelligence (AI), and the Internet of Things (IoT) allows daily operations to gain precision, repeatability, and objectivity, thereby reducing reliance on human judgment.

The core purpose of this transformation is to leverage technology to optimize operations, cut costs, and elevate animal welfare through real-time, data-driven decisions. Below, we analyze how these tools are redefining aquaculture management.

Key takeaways

- Digital Transition: The industry is evolving from subjective manual practices to automated processes based on evidence and objective data.

- Cost Efficiency: Precision feeding via AI can reduce the Feed Conversion Ratio (FCR) by 5% to 15%, drastically lowering operating expenses.

- Non-invasive Monitoring: Computer vision and acoustics allow for biomass estimation and pathology detection without physical handling, minimizing stress on the fish.

- Proactive Water Management: Predictive models anticipate variations in water quality, facilitating rapid interventions against hypoxia risks or disease outbreaks.

From traditional management to technological precision

Historically, fish production stages have depended on the manual labor of expert operators. While this experience is valuable, traditional systems have critical limitations: they are labor-intensive, generate fragmented data, and hinder objective animal welfare assessment.

The radical difference lies in information processing. While traditional systems isolate data and limit quality controls to random sampling, smart systems digitize the entire production chain. In Aquaculture 5.0, every animal or shoal becomes a constant data source. This eliminates subjectivity; instead of visually estimating welfare, technology allows it to be measured with exact indicators.

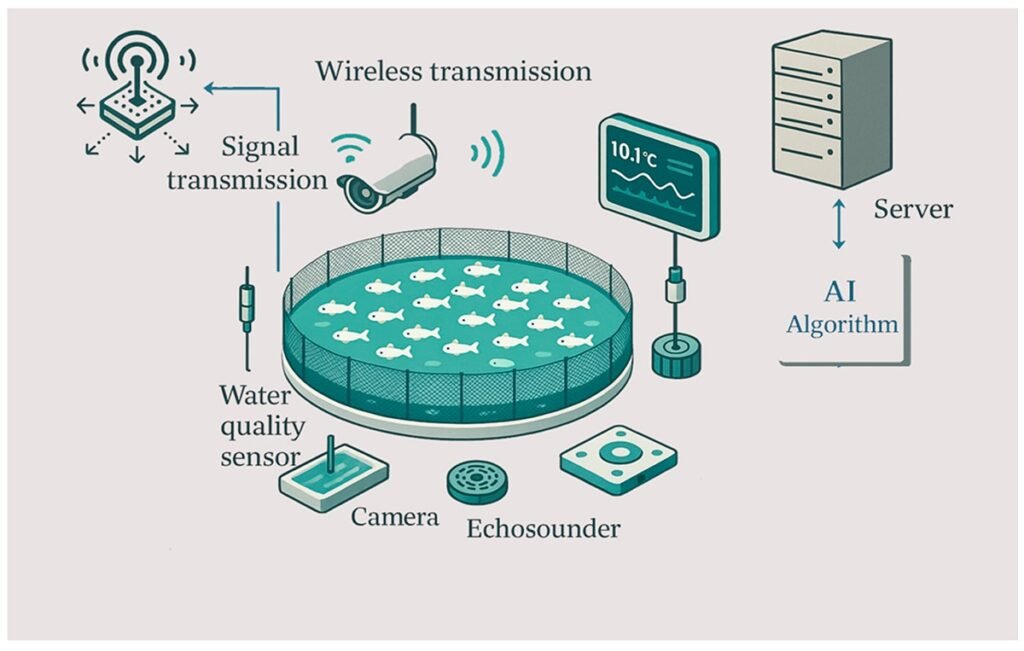

The farm’s “Eyes” and “Ears”: Computer vision and acoustics

To achieve this level of precision, the industry is adopting technologies that emulate and surpass human senses.

Computer Vision

The use of optical cameras and computational processing offers an automated, non-invasive method to analyze fish characteristics, remotely monitoring size, morphology, and movement patterns.

- Stereo Vision: Employs two cameras to measure depth and analyze 3D movement with a reduced margin of error (3-5%).

- LiDAR Technology: Uses laser beams to measure distances and movements with extreme accuracy, extracting detailed morphological data.

- Infrared: Essential for monitoring at night or in low-light conditions, leveraging the low absorption of this light in water.

Acoustic Methods

Sound is a vital tool, especially in turbid waters where optics are limited. Active acoustics (sonars and echosounders) estimate biomass and spatial distribution. Meanwhile, passive acoustics use hydrophones to capture swimming and feeding sounds, helping to quantify the shoal’s appetite.

Artificial Intelligence and IoT: The Brain of the Operation

The massive data flow from cameras and sensors requires advanced processing. This is where Artificial Intelligence (AI) and Machine Learning (ML) intervene. These algorithms detect patterns, predict outcomes (such as growth rates or health risks), and automate decision-making.

Stay Always Informed

Join our communities to instantly receive the most important news, reports, and analysis from the aquaculture industry.

Predictive water quality monitoring

Control of critical variables like Dissolved Oxygen (DO), temperature, and pH is performed via modern sensors connected through IoT. The true revolution lies in predictive capability. Algorithms such as Support Vector Machines (SVM) have demonstrated up to 99% accuracy in predicting water quality in intensive systems. This empowers producers to anticipate problems, automatically activating aerators before an oxygen crisis occurs.

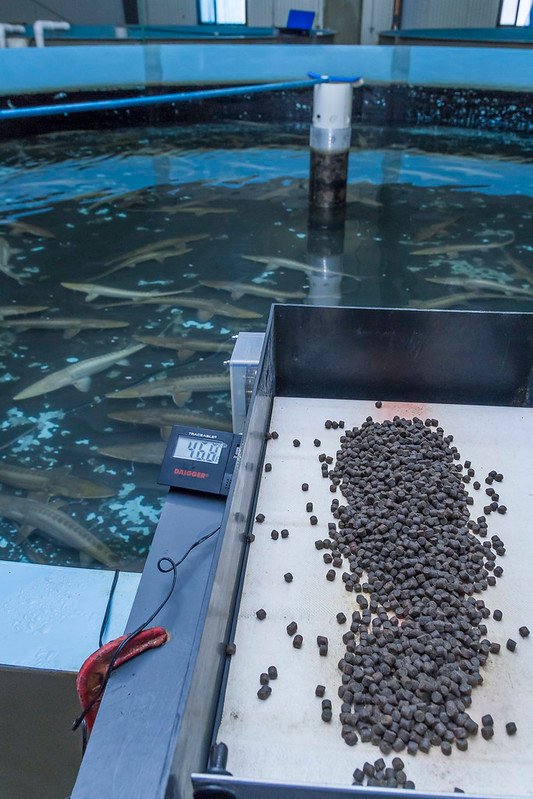

Feed optimization

Feed represents between 40% and 50% of production costs. AI offers a solution through “smart feeding.” By analyzing swimming behavior and chewing sounds, systems determine fish satiety. Advanced algorithms, such as Convolutional Neural Networks (CNN), process images to adjust feed delivery in real time. This reduces economic waste and improves water quality by minimizing organic residue.

Biomass estimation and welfare

Traditional weighing involved removing fish from the water, causing stress and potential physical damage. Today, computer vision and ML allow for contactless weight and size estimation. Furthermore, swim pattern analysis functions as an early warning system: if a group changes its speed or distribution, the system immediately notifies the producer of potential stress or disease situations.

Challenges and future perspectives

Despite evident advantages, implementing Aquaculture 5.0 faces obstacles. Initial infrastructure costs are high, and there is a lack of standardization among different market devices. Additionally, managing these systems demands qualified personnel with new technological competencies.

However, the future points toward total automation. Technologies such as “Digital Twins“ (virtual farm simulations) and underwater robotics for maintenance tasks are already being explored, paving the way to the next productive frontier.

Conclusion

Precision Aquaculture represents an unavoidable evolution toward a smart production model. By integrating sensors, AI, and connectivity, farms achieve lower operating costs, maximize production, and substantially improve animal welfare and sustainability. Although technical challenges persist, adopting these advanced tools redefines the limits of modern aquaculture, enabling informed decisions for a more efficient future.

Reference (open access)

D’Agaro, E. (2025). Fish Farming 5.0: Advanced Tools for a Smart Aquaculture Management. Applied Sciences, 15(23), 12638. https://doi.org/10.3390/app152312638

Editor at the digital magazine AquaHoy. He holds a degree in Aquaculture Biology from the National University of Santa (UNS) and a Master’s degree in Science and Innovation Management from the Polytechnic University of Valencia, with postgraduate diplomas in Business Innovation and Innovation Management. He possesses extensive experience in the aquaculture and fisheries sector, having led the Fisheries Innovation Unit of the National Program for Innovation in Fisheries and Aquaculture (PNIPA). He has served as a senior consultant in technology watch, an innovation project formulator and advisor, and a lecturer at UNS. He is a member of the Peruvian College of Biologists and was recognized by the World Aquaculture Society (WAS) in 2016 for his contribution to aquaculture.