Researchers Develop a “Multi-Fidelity” Model to Predict Marine Cage Deformations and Mooring Loads in Real-Time, Driving Aquaculture 4.0

Marine aquaculture faces a perpetual challenge: the relentless dynamics of the ocean. As the industry expands into exposed offshore waters, farming cages undergo severe deformation due to waves and currents. This not only compromises structural integrity but also jeopardizes fish welfare.

To mitigate these risks, a research team from the Massachusetts Institute of Technology (MIT) and SINTEF Ocean (Norway) has developed a pioneering solution: a “multi-fidelity digital twin.” This technology integrates artificial intelligence, computational simulations, and real sensor data to monitor cages with unprecedented precision and reduced costs.

The study, recently published in Scientific Reports, promises to transform safety protocols and facilitate the operations of autonomous underwater vehicles.

- 1 Key study highlights

- 2 The challenge of flexible offshore structures

- 3 What is a Multi-Fidelity Digital Twin?

- 4 The Role of Artificial Intelligence (NARGP)

- 5 Validation in the Ocean “Lab”: SINTEF ACE

- 6 Results: Precision that safeguards investments

- 7 Towards Aquaculture 4.0

- 8 Entradas relacionadas:

Key study highlights

- Real-Time Prediction: The new framework instantly calculates net deformation and mooring tension, overcoming the latency of traditional models.

- Data Fusion (Multi-Fidelity): It combines cost-effective simulations (low-fidelity) with select data from physical sensors (high-fidelity) to correct deviations without incurring high instrumentation costs.

- Operational Safety: It enables the safe navigation of Remotely Operated Vehicles (ROVs) around deformed structures, preventing collisions.

- Field Validation: The system proved its efficacy under extreme winter conditions at the SINTEF ACE research farm in Norway.

The challenge of flexible offshore structures

Unlike wind turbines or vessels, aquaculture cages are intrinsically flexible structures. Composed of millions of threads, these nets deform drastically under hydrodynamic action. According to the authors, this flexibility creates two critical issues:

- Reduced Habitable Volume: Deformation compresses the space, increasing stress on the fish and reducing available oxygen, which affects growth and survival.

- Risk of Escapes and Collisions: Extreme loads can snap components. Furthermore, autonomous robots (ROVs) require precise, real-time knowledge of the net’s geometry to avoid crashes that could lead to escapes.

Historically, the industry has oscillated between complex numerical simulations (too slow for live use) or physical sensors (expensive and limited to isolated points).

What is a Multi-Fidelity Digital Twin?

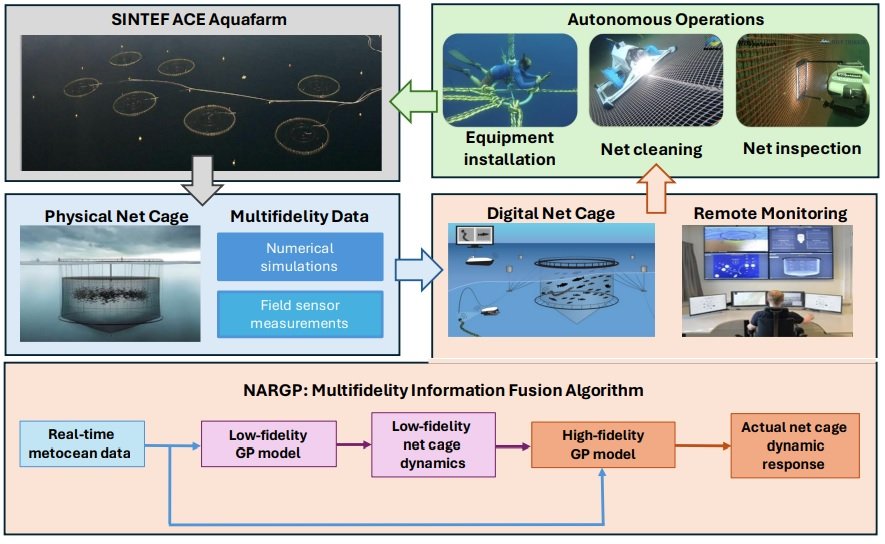

The core innovation of this work, led by Eirini Katsidoniotaki alongside Biao Su, Eleni Kelasidi, and Themistoklis P. Sapsis, lies in its hybrid approach. Instead of simulating the full physics of the water (which would require supercomputers) or saturating the cage with sensors, the team designed a system under the Digital Twin concept that combines:

- Low-Fidelity (Fast Simulation): A simplified numerical model (based on FhSim software) that estimates cage movement. It is fast, though prone to errors as it misses details like biofouling.

- High-Fidelity (Real Data): Precise information derived from strategic depth and load sensors installed on the cage.

The Role of Artificial Intelligence (NARGP)

The core uniting these two worlds is a machine learning algorithm called the Nonlinear Autoregressive Gaussian Process (NARGP).

This algorithm identifies and learns the complex correlations between the simplified simulation and measured reality. In essence, the AI detects “where the simulation fails” and corrects it in real-time using sensor data. The result is an accurate reconstruction of the entire cage structure in seconds, with minimal computational cost.

Stay Always Informed

Join our communities to instantly receive the most important news, reports, and analysis from the aquaculture industry.

Validation in the Ocean “Lab”: SINTEF ACE

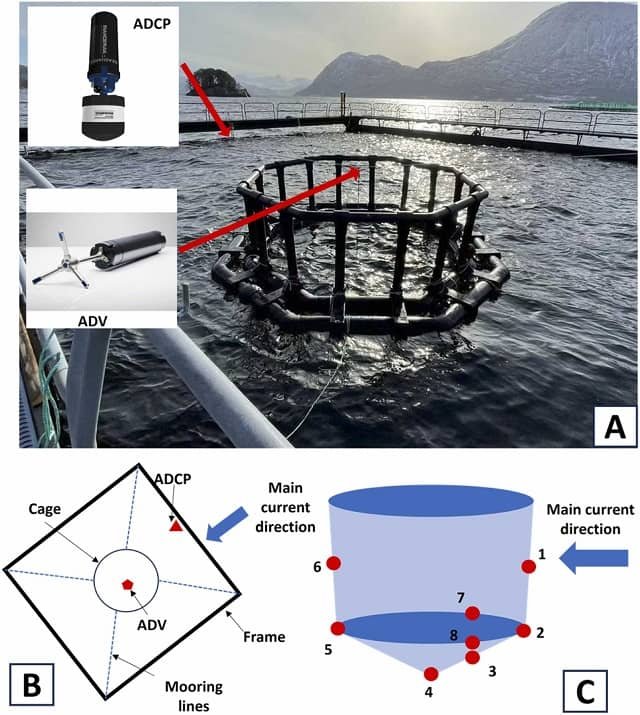

To test the system’s robustness, researchers validated their digital twin at the SINTEF ACE facilities in Buholmen, Norway.

The tests were conducted during the winter of 2020 (January–March) under severe marine conditions, with waves up to 1.6 meters and strong currents. While the simple simulation model showed significant deviations—ignoring factors such as the extra weight of biofouling—the multi-fidelity digital twin corrected these errors, aligning almost perfectly with load and pressure sensor measurements.

Results: Precision that safeguards investments

The study highlights two high-value technical achievements for producers:

- Early Warning: The model accurately predicted tension in anchor lines based on environmental conditions, acting as a preventive system against catastrophic failures.

- Live 3D Topology: The system reconstructed the full shape of the deformed net. Compared to advanced techniques like Graph Convolutional Networks (GCNs), the multi-fidelity approach proved sufficiently lightweight and robust to operate on-the-fly.

This empowers operators to visualize the underwater behavior of their assets on-screen in real-time, without waiting for engineering analysis.

Towards Aquaculture 4.0

The implementation of these digital twins marks a milestone for sector automation (Aquaculture 4.0). Practical applications include:

- Safe Autonomous Operations: Underwater vehicles (UUV/ROV) can plan inspection or cleaning routes without human intervention, knowing the exact position of the net.

- Cost Optimization: Reducing reliance on excessive physical hardware lowers Capital Expenditure (CapEx) and maintenance expenses.

- Strategic Decision Making: It allows for the simulation of virtual scenarios in the face of impending storms, optimizing mooring designs and maintenance planning.

Conclusion

The collaboration between MIT and SINTEF Ocean demonstrates that speed is not at odds with accuracy. Thanks to machine learning surrogate models, total control over structural dynamics in aquaculture is possible. This technology is a fundamental step toward automated farms in the open ocean, ensuring sustainable and safe food production.

Contact

Eirini Katsidoniotaki

Department of Mechanical Engineering, Massachusetts Institute of Technology

Cambridge, MA, 02138, USA

Email: eirka289@mit.edu

Reference (open access)

Katsidoniotaki, E., Su, B., Kelasidi, E., & Sapsis, T. P. (2025). Multifidelity digital twin for real-time monitoring of structural dynamics in aquaculture net cages. Scientific Reports. https://doi.org/10.1038/s41598-025-27812-1

Editor at the digital magazine AquaHoy. He holds a degree in Aquaculture Biology from the National University of Santa (UNS) and a Master’s degree in Science and Innovation Management from the Polytechnic University of Valencia, with postgraduate diplomas in Business Innovation and Innovation Management. He possesses extensive experience in the aquaculture and fisheries sector, having led the Fisheries Innovation Unit of the National Program for Innovation in Fisheries and Aquaculture (PNIPA). He has served as a senior consultant in technology watch, an innovation project formulator and advisor, and a lecturer at UNS. He is a member of the Peruvian College of Biologists and was recognized by the World Aquaculture Society (WAS) in 2016 for his contribution to aquaculture.