In modern aquaculture, plastics are ubiquitous. From nets and pipes to pond liners, their durability and cost-effectiveness have made them an industry standard. However, this reliance raises a critical biosecurity question: what happens on the surface of these materials at a microscopic level?

Any surface submerged in water is quickly colonized by microorganisms, forming a thin, viscous layer known as a biofilm. When this film forms on plastic, it is termed the “plastisphere,” and it can become a refuge for Potentially Pathogenic to Humans Bacteria (PPHB) and Antibiotic-Resistant Bacteria (ARB).

A recent study in FEMS Microbiology Ecology has shed light on this issue, investigating how the type of material—and, critically, its immersion time—shapes the bacterial risk profile on an aquaculture farm. Their findings, far from demonizing plastics, offer a nuanced perspective that could change how producers manage their equipment to mitigate health risks.

- 1 The experiment: Analyzing risk under real-world conditions

- 2 Pathogens are initial, not late-stage, colonizers

- 3 Plastics don’t harbor more pathogens, but they do foster a specific profile

- 4 A unique antibiotic resistance profile for plastics

- 5 Conclusions for the aquaculture industry

- 6 Entradas relacionadas:

The experiment: Analyzing risk under real-world conditions

To understand the day-to-day dynamics on a farm, researchers from the University of Montpellier, the University of Toliara, Indian Ocean Trepang (IOT), and the Institut Pasteur de Madagascar conducted a three-month experiment at a sea cucumber (Holothuria scabra) farming facility in Madagascar.

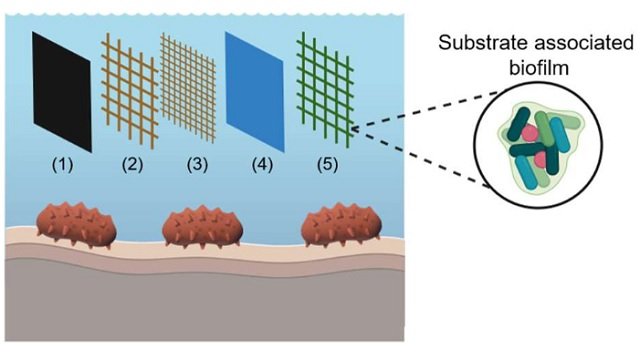

The scientific team submerged panels of five different materials to observe how they were colonized by bacteria:

- Three common aquaculture plastics: a polyethylene (PE) liner and two types of polyamide (PA) nets (one fine-mesh, one wide-mesh).

- Two non-plastic materials: a hemp net, proposed as a biodegradable alternative, and a glass panel as an inorganic control surface.

Over the three months, researchers sampled the biofilms at seven key intervals, from the first 6 hours to 90 days of immersion. Using genetic analysis and bacterial cultures, they identified the communities of potential pathogens and assessed their resistance profiles against 24 types of antibiotics.

Pathogens are initial, not late-stage, colonizers

One of the study’s most surprising findings contradicts the intuition that “older” equipment is necessarily “more dangerous.” The analysis revealed that the highest relative abundance of PPHB on all solid surfaces was reached within the first 24 hours of immersion.

After this initial peak, the proportion of these potential pathogens decreased significantly over time on several materials. This suggests that many of these bacteria are opportunistic or “pioneer” colonizers: they arrive and establish themselves quickly but are eventually outcompeted by other, non-pathogenic bacterial communities that are better adapted to the mature biofilm environment.

What does this mean for the producer? The idea that pathogen risk increases linearly with equipment use-time does not seem to hold true. Therefore, simply increasing the frequency of equipment cleaning might not be the most effective strategy and should be adapted to the specific context and management goals of each farm.

Stay Always Informed

Join our communities to instantly receive the most important news, reports, and analysis from the aquaculture industry.

Plastics don’t harbor more pathogens, but they do foster a specific profile

The study directly addressed the key question: Are plastics a magnet for pathogens compared to other materials? The answer is no, but with a critical caveat.

In terms of quantity, plastics did not harbor more pathogenic bacteria than glass or hemp. In fact, during the first 72 hours, the hemp net showed the highest proportion of PPHB, likely because its organic nature serves as a nutrient source.

However, the devil is in the details. While the quantity was not higher, the composition of the bacterial community was different. The analysis identified that plastic surfaces were a “biomarker” for a well-known bacterial family in aquaculture: Vibrionaceae.

The abundance of Vibrionaceae on plastics was at least four times higher than that found on hemp, glass, or in the surrounding water. This family includes notorious pathogens like Vibrio parahaemolyticus and Vibrio vulnificus, which are responsible for vibriosis in fish and shrimp and foodborne illness in humans. The Staphylococcaceae family was also notably more abundant on plastics.

- Practical implication: While plastic equipment does not necessarily accumulate more pathogens overall, it does appear to select for and act as a specific reservoir for the Vibrio genus, which could increase the likelihood of vibriosis outbreaks on the farm.

A unique antibiotic resistance profile for plastics

The other side of the biosecurity coin is antibiotic resistance. The study found that the farm, in general, presented a high-risk environment for antibiotic contamination. But what role did plastics play?

Again, the results were unexpected. Bacteria isolated from plastic substrates showed a lower Multiple Antibiotic Resistance (MAR) index than those found on glass and in the seawater.

However, as with the pathogens, the key was not the amount of resistance, but the type. Biofilms on plastics displayed a specific and statistically different resistance profile: their bacteria were notably more resistant to quinolones, a critical class of antibiotics. In contrast, bacteria in the water were more resistant to beta-lactams.

- Practical implication: In this context, plastics do not appear to be a general amplifier of multidrug resistance. However, they do function as a niche that selects for and harbors bacteria with specific resistance to quinolones, representing a particular health risk that must be considered.

Conclusions for the aquaculture industry

This study demonstrates that the relationship between plastics, pathogens, and antibiotic resistance is far more complex than previously thought. Producers can draw several valuable conclusions:

- Risk changes over time: The highest potential pathogen load occurs in the initial stages of new equipment colonization (the first 24-72 hours), not necessarily after months of use.

- Plastic selects, it doesn’t accumulate more: The true risk of plastics is not that they harbor more dangerous bacteria overall, but that they appear to select for a specific profile, acting as reservoirs for the Vibrionaceae family and quinolone-resistant bacteria.

- Management is key: Material composition and immersion time are levers that producers can use to manage microbiological risks. For example, knowing the specific profile of plastics can guide better disinfection strategies or the choice of alternative materials like hemp, while also weighing their own distinct risk profiles.

Ultimately, understanding the dynamics of the “plastisphere” allows for more informed and strategic decisions about equipment management—a fundamental step in protecting the health of farmed animals, workers, and, ultimately, consumers.

Contact

Jeanne Naudet

MARBEC, Univ Montpellier, CNRS, Ifremer, IRD

Montpellier, France

E-mail: jeanne.naudet@umontpellier.fr

Reference (open access)

Naudet, J., Auguet, J., Bouvier, T., Rakotovao, R., Motte, T., Gaumez, L., Crucitti, T., & Rieuvilleneuve, F. 2025. Polymers and immersion time shape bacterial pathogen and antibiotic resistance profiles in aquaculture facilities. FEMS Microbiology Ecology. 2025, fiaf076 https://doi.org/10.1093/femsec/fiaf076

Editor at the digital magazine AquaHoy. He holds a degree in Aquaculture Biology from the National University of Santa (UNS) and a Master’s degree in Science and Innovation Management from the Polytechnic University of Valencia, with postgraduate diplomas in Business Innovation and Innovation Management. He possesses extensive experience in the aquaculture and fisheries sector, having led the Fisheries Innovation Unit of the National Program for Innovation in Fisheries and Aquaculture (PNIPA). He has served as a senior consultant in technology watch, an innovation project formulator and advisor, and a lecturer at UNS. He is a member of the Peruvian College of Biologists and was recognized by the World Aquaculture Society (WAS) in 2016 for his contribution to aquaculture.