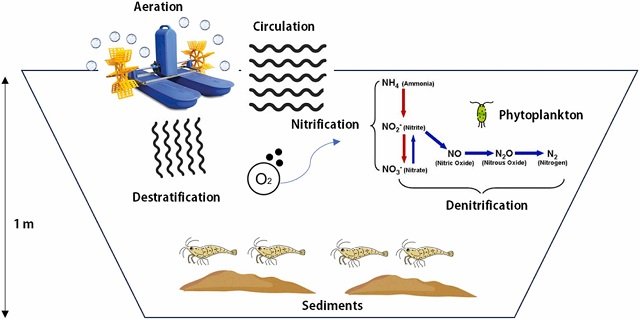

Intensive and semi-intensive shrimp farming faces a constant challenge: maintaining optimal dissolved oxygen (DO) levels in ponds. Mechanical aeration, while essential, represents one of the largest operating costs, consuming up to 95% of a farm’s total energy. The manual and inefficient operation of this equipment not only increases expenses but also puts production at risk.

A recent review article published in Aquacultural Engineering explores a comprehensive solution that could change this paradigm. The research, led by P. Jayraj of the Indian Institute of Technology, analyzes how the synergistic combination of three technologies—CFD-optimized design, automation with the Internet of Things (IoT), and the use of solar energy—can transform traditional paddlewheel aerators into high-efficiency tools for truly sustainable shrimp farming.

The problem of traditional aeration

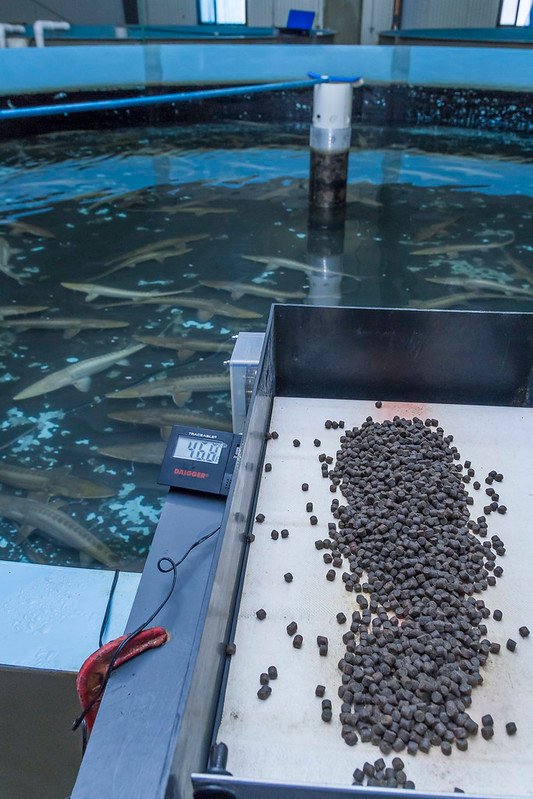

In intensive aquaculture, DO management is critical. Levels below 5 mg/L can cause stress in shrimp, reduce their appetite, and, in extreme cases, lead to mass mortality. Paddlewheel aerators are the most popular tool for this task, especially in Asia, due to their effectiveness in oxygenating and circulating water.

However, their operation is often an exercise of “better safe than sorry.” Many producers operate aerators continuously or for long periods based on experience, resulting in excessive energy consumption. A study in Thailand, for example, estimated that aerators can operate for about 20 hours a day, accumulating a consumption of up to 36,000 kWh per crop cycle. The key, then, is not just to aerate, but to do it intelligently.

A solution on three technological fronts

The review article proposes that true optimization comes not from a single improvement, but from the integration of three advanced technological fields.

Superior design through computational fluid dynamics (CFD)

Not all paddlewheel aerators are the same. Their efficiency, measured as the Standard Oxygen Transfer Rate (SOTR) and Standard Aeration Efficiency (SAE), varies enormously depending on their blade design. The study highlights that Computational Fluid Dynamics (CFD) is a precise tool for modeling water flow and oxygen distribution, allowing for the optimization of the shape, angle, and number of blades to maximize air-water interaction and minimize energy consumption.

The research shows notable differences:

- US designs (spiral type): Exhibit higher efficiency, with SAE values that can reach 2.02 to 2.9 kgO₂/kW-h.

- Taiwanese designs: Although more economical and popular in Asia, their efficiency is considerably lower, with SAEs of 0.78 to 1.18 kgO₂/kW-h in traditional designs.

- CFD modifications: Studies that used CFD to optimize blades, for example, with a furrowed design, managed to raise the SAE to 2.72 kgO₂/kW-h, demonstrating the potential of this technique to drastically improve performance.

Precise and automatic operation with the Internet of Things (IoT)

Operating an aerator only when strictly necessary is the most direct way to save energy. The Internet of Things (IoT) technology makes this possible by shifting from experience-based management to data-driven management.

An IoT system for aquaculture, in its most basic form, consists of:

Stay Always Informed

Join our communities to instantly receive the most important news, reports, and analysis from the aquaculture industry.

- Perception Layer: Sensors that measure parameters like DO and temperature in real-time.

- Network Layer: Connectivity (Wi-Fi, LoRa, etc.) that transmits the data.

- Application Layer: A cloud platform or mobile app that processes the data and allows the producer to monitor and control the actuators (the aerator).

The study cites a revealing experiment where an automated aeration system, which activated only when the DO fell below a threshold, consumed 137 kW-h, compared to the 702 kW-h of a manually controlled system that operated 12 hours each night. Both systems maintained similar pond conditions and shrimp productivity. This represents an energy saving of over 80% without sacrificing crop performance.

Independence and sustainability with solar energy

To break the dependence on the electrical grid and its fluctuating costs, solar photovoltaic (PV) energy is the final piece of the puzzle. Integrating solar panels to power the aerators not only reduces operating expenses but also minimizes environmental impact.

A key advancement mentioned in the study is the replacement of conventional alternating current (AC) motors with brushless direct current (BLDC) motors. BLDC motors are more energy-efficient and their control is simpler through microcontrollers, making them ideal for systems powered by solar energy and controlled by IoT. Although prototypes exist, the research underscores the need to develop 1 to 2 hp BLDC motors, which is the power that commercial producers actually use.

Gaps and the road to the future

Despite the enormous potential, the review concludes that most research has been fragmented. There are studies on CFD optimization, others on IoT prototypes, and some on solar energy, but a comprehensive investigation that combines all three technologies into a single, commercially viable paddlewheel aerator system is lacking.

The future of smart aeration goes even further. The document points to the need to explore the application of Machine Learning (ML) and Artificial Intelligence (AI). These systems could analyze the data collected by the IoT to predict oxygen depletion trends and adjust the operation of the aerators proactively, taking efficiency to a whole new level.

In conclusion, the integration of CFD, IoT, and solar energy offers a clear path to improve efficiency, reduce costs, and increase the sustainability and profitability of shrimp farming operations. The development and validation of these integrated systems is not just a research opportunity, but a necessity for the evolution of the global aquaculture industry.

Contact

P. Jayraj

Agricultural and Food Engineering Department, Indian Institute of Technology

Kharagpur, India.

Email: jayrajp@agfe.iitkgp.ac.in

Reference (open access)

Jayraj, P., Sahoo, S., Jana, P., & Prem, R. (2025). CFD Optimised Solar Powered IoT Integrated Paddlewheel Aerator for Sustainable Shrimp Farming – A Review. Aquacultural Engineering, 102583. https://doi.org/10.1016/j.aquaeng.2025.102583

Editor at the digital magazine AquaHoy. He holds a degree in Aquaculture Biology from the National University of Santa (UNS) and a Master’s degree in Science and Innovation Management from the Polytechnic University of Valencia, with postgraduate diplomas in Business Innovation and Innovation Management. He possesses extensive experience in the aquaculture and fisheries sector, having led the Fisheries Innovation Unit of the National Program for Innovation in Fisheries and Aquaculture (PNIPA). He has served as a senior consultant in technology watch, an innovation project formulator and advisor, and a lecturer at UNS. He is a member of the Peruvian College of Biologists and was recognized by the World Aquaculture Society (WAS) in 2016 for his contribution to aquaculture.