Recirculating aquaculture systems (RAS) have become a popular method for farming fish and other aquatic species. However, these systems generate wastewater containing nutrients from fish excreta and leftover feed, which can negatively impact the environment if not managed properly.

One potential solution is the use of microalgae to remediate these nutrients. A recent study published in Bioresource Technology by scientists from NORCE Norwegian Research Centre AS, Wageningen University and Research, and the University of Bergen investigated the nutrient-remediation potential of cultivating microalgae in RAS wastewater.

Circular Economy in RAS

The circular economy emphasizes the importance of utilizing existing value chains to their fullest capacity, including reducing secondary waste streams by viewing them as resources for added value. One such opportunity is capturing waste products from aquaculture production, including nutrient-rich effluent water from RAS.

Effluent water from RAS contains nutrient concentrations that vary depending on the system, fish species, and feeding regimes and is often discharged directly into nearby water bodies. However, the large volumes of water emitted by RAS result in substantial nutrient release over a year. A strategy to recover nutrients from RAS effluent water is biological remediation through microalgae cultivation.

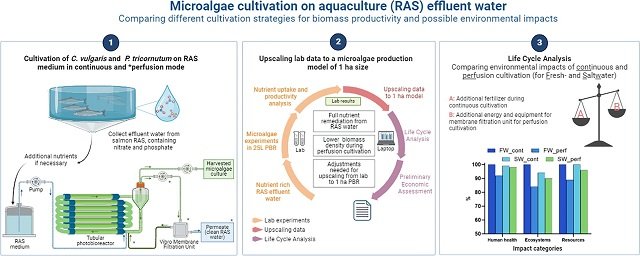

Microalgae, natural filters, can efficiently absorb nutrients from wastewater and convert them into valuable biomass. In this study, scientists compared two cultivation modes: continuous and perfusion.

Continuous vs. Perfusion Cultivation

- Continuous Cultivation: This mode supplies a continuous flow of nutrient-rich effluent water to the reactor while microalgae biomass is continuously removed. Although this method can achieve high biomass densities (up to 3.88 g L⁻¹), it requires additional nutrient supplementation to sustain optimal growth.

- Perfusion Cultivation: This approach uses a membrane filtration system to retain microalgae biomass within the reactor while nutrient-rich effluent water circulates continuously. This method also achieves high biomass densities (up to 3.59 g L⁻¹) without needing additional nutrient supplementation.

Environmental and Economic Considerations

A life cycle assessment (LCA) was conducted to evaluate the environmental impact of both cultivation modes. While perfusion cultivation appeared to have a smaller environmental footprint for relatively low nutrient concentrations, it also required additional equipment and energy, leading to higher operational and capital costs.

Implications for the Aquaculture Industry

The findings of this study have significant implications for the aquaculture industry, particularly for RAS users. By using microalgae to remediate nutrients in RAS effluent water, farmers can reduce the environmental impact of their operations and potentially increase profitability.

The results also underscore the importance of considering the environmental sustainability of different cultivation modes and balancing environmental impact with economic costs.

Conclusion

The study demonstrates the potential of microalgae cultivation to remediate nutrients in RAS effluent water. The results highlight the importance of environmental sustainability in different cultivation modes and the trade-offs between environmental impact and economic costs.

Stay Always Informed

Join our communities to instantly receive the most important news, reports, and analysis from the aquaculture industry.

Key Findings:

- Nutrient Remediation: Both cultivation methods effectively removed nutrients from RAS effluent water.

- High-Density Biomass Production: Continuous cultivation with additional nitrate fertilization and perfusion cultivation with membrane filtration achieved high biomass productivity (up to 2.15 g L⁻¹ d⁻¹).

- Environmental Sustainability: Perfusion cultivation was found to be more environmentally sustainable for RAS effluent with low nutrient concentrations, despite higher operational and investment costs.

- Environmental Impact: Photobioreactor infrastructure and electricity consumption were identified as the primary contributors to environmental impacts during cultivation.

However, further research is needed to fully understand the benefits and limitations of microalgae cultivation in RAS and to develop more sustainable and cost-effective solutions for the aquaculture industry.

The study was funded by the Norwegian Research Council and Aquafeed Technology Centre, and by the European Union through the INNOAQUA project.

Contact

Hanna Böpple

NORCE Norwegian Research Centre AS

Thormøhlens Gate 53, 5006 Bergen, Norway

Email: habp@norceresearch.no

Reference (open access)

Böpple, H., Slegers, P. M., Breuhaus, P., & Kleinegris, D. M. (2024). Comparing continuous and perfusion cultivation of microalgae on recirculating aquaculture system effluent water. Bioresource Technology, 131881. https://doi.org/10.1016/j.biortech.2024.131881

Editor at the digital magazine AquaHoy. He holds a degree in Aquaculture Biology from the National University of Santa (UNS) and a Master’s degree in Science and Innovation Management from the Polytechnic University of Valencia, with postgraduate diplomas in Business Innovation and Innovation Management. He possesses extensive experience in the aquaculture and fisheries sector, having led the Fisheries Innovation Unit of the National Program for Innovation in Fisheries and Aquaculture (PNIPA). He has served as a senior consultant in technology watch, an innovation project formulator and advisor, and a lecturer at UNS. He is a member of the Peruvian College of Biologists and was recognized by the World Aquaculture Society (WAS) in 2016 for his contribution to aquaculture.