In fish farming, the larval stage represents a critical “bottleneck.” Unlike adult fish, larvae frequently reject dry artificial diets, leading to alarming mortality rates in the absence of suitable live feed. While Artemia (small crustaceans) are the standard solution, their administration presents an operational dilemma: manual feeding is inconsistent and time-consuming, whereas commercial automated systems are prohibitively expensive for many facilities.

A research team from the South Dakota Department of Game, Fish and Parks, alongside South Dakota State University, recently published an ingenious solution in the World Journal of Engineering and Technology: a high-efficiency, low-budget Artemia dispenser designed for integration into Recirculating Aquaculture Systems (RAS).

Key Insights

- Technological Democratization: A new design enables the construction of an automated feeder for just $20 USD, compared to $1,500 USD for commercial alternatives.

- Simple Precision Engineering: The system utilizes SDR 35 PVC components and drip valves to ensure a constant supply of Artemia.

- The Viscosity Challenge: Research identified that the density of the Artemia mixture and cyst debris are the primary obstacles to seamless automation.

- Operational Efficiency: Although the initial target was 6 hours, the prototype achieved 3 hours of continuous feeding, significantly outperforming the irregularity of manual supply.

Engineering with Accessible Materials

The device, dubbed a “gravity-fed drip dispenser,” moves away from electronic complexity to prioritize mechanical robustness.

Core Components

- Dispenser Body: Constructed from 152 mm diameter SDR 35 PVC piping, with a total capacity of 5.5 liters.

- Oxygenation System: An internal air stone connected to an air pump ensures that the Artemia remains homogeneously suspended and sufficiently oxygenated.

- Flow Control: Utilizes PEX tubing and a series of adapters that allow for the modulation of feed output.

The brilliance of the design lies in its simplicity. By using common hardware store materials, the total manufacturing cost is approximately $20 USD, representing a savings of up to 98% compared to high-end equipment that can exceed $1,500 USD.

Methodology and Optimization: The Art of Preventing Clogs

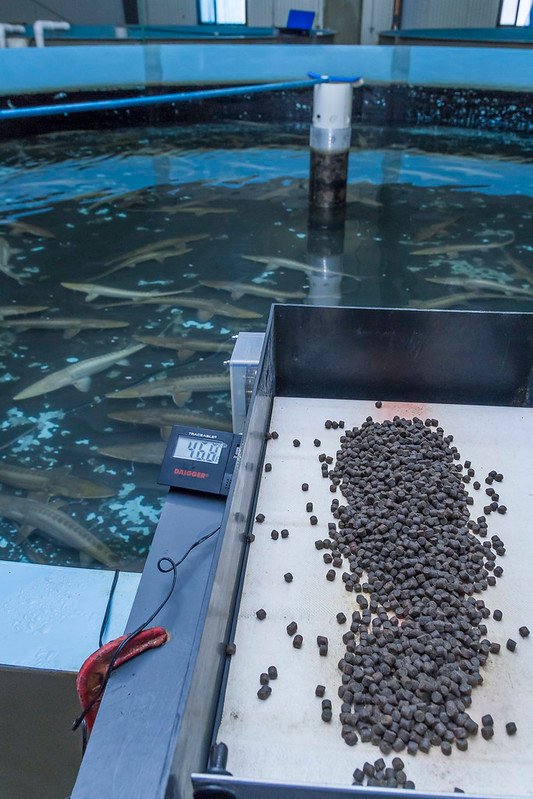

The prototype was evaluated during the rearing of muskellunge larvae (Esox masquinongy). Initially, researchers faced consistency issues due to the high viscosity of the nauplii mixture and clogging caused by unhatched cysts. To resolve this, the study details two critical “retrofits” or improvements:

- Progressive Reduction: A series of vinyl tubing segments with decreasing diameters (from 9.5 mm down to a 2.38 mm fuel line) was implemented to stabilize the flow.

- Irrigation Valve: The addition of a Rain Bird brand drip valve allowed for acceptable precision in feed delivery.

Furthermore, it was discovered that adding a salt buffer (30 ppt) before introducing the Artemia significantly reduced the mixture’s viscosity, allowing the fluid to descend more easily through the drip system.

From Theory to Practice in the Fish Hatchery

The design objective was to achieve 6 hours of continuous feeding to cover a 12-hour cycle with only two daily refills. Under real-world conditions, the system reached 3 hours of optimal operation before requiring intervention. Despite falling short of the 6-hour goal, the benefits remain tangible:

- Extended Availability: Fish larvae have access to live feed for significantly longer periods than with intermittent manual feeding.

- Labor Reduction: Although more refills are required than initially anticipated, the total staff time dedicated to feeding decreases drastically.

- Integration: The dispenser’s mount was adapted to fit seamlessly into existing culture tanks, facilitating immediate implementation.

Limitations and Recommendations

The study is transparent regarding the system’s weaknesses. The dispenser’s success depends critically on cleanliness: it is imperative to remove unhatched cysts and empty shells, as any solid residue instantaneously blocks the small-diameter drip lines. Furthermore, the minimum clog-free dosing rate was established at 46 ml/min, which dictates the speed at which the 5.5-liter reservoir is depleted.

Stay Always Informed

Join our communities to instantly receive the most important news, reports, and analysis from the aquaculture industry.

Global Impact and Conclusions

This breakthrough represents a significant step toward accessible precision aquaculture. By publishing an open-source, low-cost design, Treft and his team provide a vital tool for research laboratories and small-scale production facilities operating on limited budgets. The ability to maintain constant Artemia nauplii densities without massive capital investment not only improves larval survival but also standardizes production processes—a key factor for the economic sustainability of the aquaculture industry.

Technical Guide for Dispenser Construction

🛠️ Bill of Materials and Costs

The system stands out for its accessibility, utilizing standard plumbing and aquarium components:

| Component | Technical Specification |

| Main Body | 152 mm diameter, 413 mm long SDR 35 PVC pipe. |

| Cap | 152 mm SDR 35 PVC plug/cap. |

| Aeration | 52 mm air stone and 9.5 mm ID (inner diameter) vinyl tubing. |

| Bottom Seal | 8 mm Uniseal. |

| Flow Outlet | 9.5 mm OD (outer diameter) PEX tubing. |

| Control (Retrofit) | Rain Bird irrigation drip valve. |

🔧 Step-by-Step Assembly Guide

Reservoir Construction (Body)

- Cut the PVC pipe to size (413 mm) and secure the cap to the base using PVC primer and cement.

- This creates a 5.5-liter capacity, leaving a 108 mm safety margin to prevent overflows.

Air System Installation

- Drill a 15.9 mm hole in the upper section of the dispenser.

- Install a 9.5 mm polyethylene elbow (MPT) and connect the internal air stone using the vinyl tubing.

- Externally, connect all dispensers to a common air line powered by a diaphragm pump to ensure a homogeneous Artemia mixture.

Dispensing Mechanism and Precision “Retrofit”

- Drill a 12 mm hole in the center of the bottom cap and insert the Uniseal.

- Push the PEX tubing through the seal.

- Precision Enhancement: Connect a series of vinyl tubing segments in decreasing order of diameter (9.5 mm → 6.4 mm → 4.8 mm).

- Attach the drip irrigation valve to the end of the 4.8 mm segment for full flow control.

Calibration and Operation

- Volume Indicator: Install an external transparent “sight glass” connected to the base to monitor the mixture level.

- Mark 0.5-liter graduations on the external tube.

- Mount the system over the fish tank using a customized stainless steel or aluminum bracket.

💡 Tips for Operational Success

To avoid the issues identified during the evaluation phase, follow these author recommendations:

- Viscosity Reduction: Add a 30 ppt salt buffer before filling with nauplii; this drastically improves the flow of the slurry.

- Critical Cleaning: It is fundamental to completely remove unhatched cysts and empty shells (chorion), as they are the primary cause of clogging in the drip lines.

- Realistic Expectations: Although the design targeted 6 hours, the reported optimal performance is 3 hours of continuous feeding. Plan refills according to this timeframe to maintain the desired feed density.

Contact

Michael E. Barnes

South Dakota Department of Game, Fish and Parks, McNenny State Fish Hatchery

Spearfish, South Dakota, USA

Email: mike.barnes@state.sd.us

Reference (open access)

Treft, C. , Fletcher, B. , Cheek, C. and Barnes, M. (2026) A Novel Artemia Dispenser for Larval Fish Culture. World Journal of Engineering and Technology, 14, 261-269. doi: 10.4236/wjet.2026.141015.

Editor at the digital magazine AquaHoy. He holds a degree in Aquaculture Biology from the National University of Santa (UNS) and a Master’s degree in Science and Innovation Management from the Polytechnic University of Valencia, with postgraduate diplomas in Business Innovation and Innovation Management. He possesses extensive experience in the aquaculture and fisheries sector, having led the Fisheries Innovation Unit of the National Program for Innovation in Fisheries and Aquaculture (PNIPA). He has served as a senior consultant in technology watch, an innovation project formulator and advisor, and a lecturer at UNS. He is a member of the Peruvian College of Biologists and was recognized by the World Aquaculture Society (WAS) in 2016 for his contribution to aquaculture.