The global salmon aquaculture industry is thriving, but its expansion presents new challenges. As fish farms venture into regions with harsher conditions (stronger currents and higher waves), the marine cages housing these fish can deform. These deformations not only compromise the integrity of the cages but also reduce vital internal volume, potentially affecting the welfare and survival of the fish.

A team of researchers from Firum, RAO SP/F, and the University of the Faroe Islands established accurate and user-friendly volume calculation methods for significantly deformed cages. The research demonstrated the practical application of these methods using pressure sensors in a real-world cage. Additionally, simulations were conducted to determine the minimum number of sensors required for satisfactory volume calculations.

The Issue: Shrinking Space, Stressed Fish

Atlantic salmon thrives in specifically designed net cages. These cages typically have a floating collar on the surface and weights at the bottom to maintain tension. However, in more turbulent waters, specialized lead collars are often used to keep the nets stretched.

Unfortunately, in more exposed locations, cages can experience significant contraction due to wave forces, which can lead to a substantial decrease in cage volume, as documented in numerous studies.

Volume reduction directly affects the welfare of farmed fish. When space is reduced, fish become stressed, affecting their health, growth rates, and even survival rates.

Therefore, accurately measuring cage volume reduction is crucial.

Measuring the Invisible: How to Assess Cage Volume Accurately

To ensure optimal fish health, it’s essential to understand how exposure to waves and currents affects cage volume. This requires reliable methods for measuring volume reduction. In research settings, markers attached to the net can be used. For operational cages, alternative methods such as acoustic markers or echo sounders can provide valuable information.

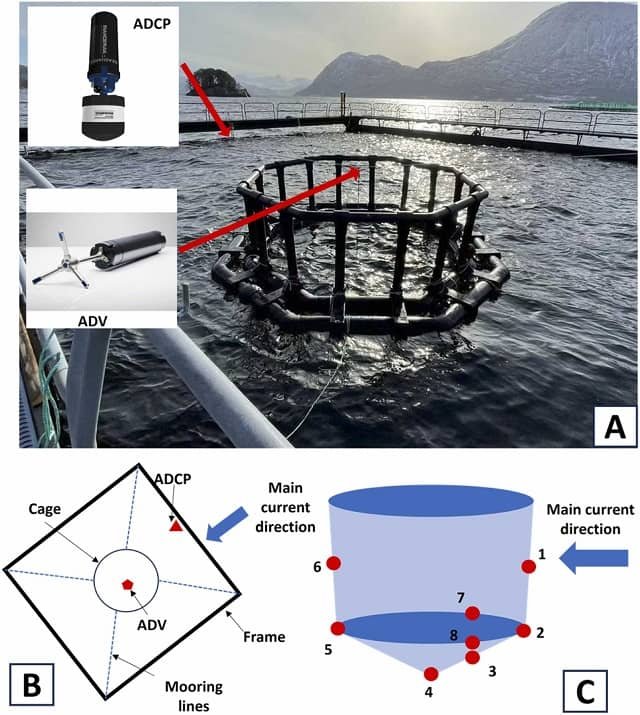

Pressure sensors placed at strategic points on the cage have traditionally been used to measure these deformations. But how can we accurately calculate contraction volume based on sensor data? This recent study delves into this critical question.

Calculating Cage Volume: Uncovering Best Practices

The study evaluated the effectiveness of these methods using data from a real-world scenario: a cage exposed to extreme weather conditions. Computer simulations were then employed to identify the ideal sensor configuration for the most accurate volume determination.

Stay Always Informed

Join our communities to instantly receive the most important news, reports, and analysis from the aquaculture industry.

The researchers identified two main methods for calculating the volume of a deformed cage:

- Surface-based methods: These methods divide the cage surface into smaller triangular sections and calculate the total volume by summing the volumes of these individual sections.

- Segment-based methods: These methods cut the interior of the cage into different segments, such as cylinders or cones, and calculate the volume of each segment independently before summing them to obtain the total volume.

Key Findings: Balancing Simplicity and Precision

- Champion of Simplicity: Cylinder-with-cone method: While praised for its ease of use, this method offered a less accurate volume estimate compared to other approaches.

- Gold Standard for Precision: Projection and Signed Volume methods: These methods emerged as the most accurate for calculating the volume of deformed cages.

- Sensor Location is Key: The study identified a crucial factor influencing accuracy: sensor location. Researchers conducted simulations to determine the minimum number of pressure sensors needed for reliable volume calculations. Their findings suggest that a strategic placement of four sensors around the edge of the cage and one at the central bottom provides a good foundation.

- For Maximum Precision: A Multi-sensor Approach: For the most accurate volume calculations, the study recommends using the Signed Volume or projection method along with a sensor distribution placed at the edge, bottom center, and along the side of the cage.

Conclusion

“In conclusion, this study compares volume calculation methods in aquaculture cages, highlighting the balance between accuracy and practical sensor implementation. Our recommendations provide guidance for optimal sensor placement and method selection,” the researchers conclude.

By implementing these volume calculation methods and optimal sensor placement, salmon producers can gain valuable insights into the structural integrity of their cages. This enables salmon farmers to take necessary actions to safeguard fish welfare and ensure the sustainability of the aquaculture industry even in challenging environments.

The study was funded by Firum, Innovations Fund Denmark, Betri Stuðul, Føroyagrunnurin frá 1971, and Mowi.

Contact

Heðin I. Abrahamsen

Firum, við Áir 11, Hvalví k, FO 430, Faroe Islands.

Email: hedin@firum.fo

https://www.firum.fo

Reference (open access)

Abrahamsen, H. I., Johannesen, T. T., Patursson, Ø., & Simonsen, K. (2024). Optimizing volume estimation in aquaculture sea cages: A comparative study of calculation methods and sensor placement. Ocean Engineering, 300, 117296. https://doi.org/10.1016/j.oceaneng.2024.117296

Editor at the digital magazine AquaHoy. He holds a degree in Aquaculture Biology from the National University of Santa (UNS) and a Master’s degree in Science and Innovation Management from the Polytechnic University of Valencia, with postgraduate diplomas in Business Innovation and Innovation Management. He possesses extensive experience in the aquaculture and fisheries sector, having led the Fisheries Innovation Unit of the National Program for Innovation in Fisheries and Aquaculture (PNIPA). He has served as a senior consultant in technology watch, an innovation project formulator and advisor, and a lecturer at UNS. He is a member of the Peruvian College of Biologists and was recognized by the World Aquaculture Society (WAS) in 2016 for his contribution to aquaculture.