Modern low-water tilapia farming aims, as in the circular bioeconomy, to reduce inputs and fully reuse waste and effluents.

Likewise, concern about diseases, market demand for clean, sustainable and ecologically correct aquaculture, are giving rise to a series of structural changes in the reuse of water and effluents through various closed recirculation systems.

Researchers from Zimmermann Aqua Solutions, the Swedish University of Agricultural Sciences, and the Chinese Academy of Fishery Sciences, published a scientific review in which they highlight that the most important innovations and trends in tilapia farming are towards the circular bioeconomy.

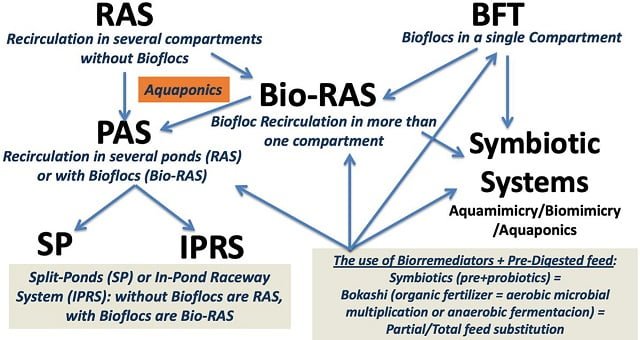

According to the researchers, the circular bioeconomy in tilapia farming is characterized by the use of various types of recirculating systems, such as biofloc technology (BFT), recirculating aquaculture systems (RASs), bio-RAS, partitioned aquaculture systems (PASs). with divided ponds, and pond recirculation systems – IPRS) and integrated multitrophic aquaculture (IMTA).

Circular bio-economy without effluents

The circular economy can be defined as the production strategy that aims to reduce inputs, in addition to production waste, close the flows or links of economic and ecological resources, decentralize production systems and identify tools to measure economic performance.

The analysis of physical resource flows is of two types:

to. Linear: where biological waste (nutrients) are reintroduced into the biosphere;

b. Circular: biological waste (nutrients) are recirculated and used again in the production system, they do not return to the biosphere.

Traditionally, the waste generated by aquaculture is deposited directly into nature, providing high levels of nitrogen and phosphorus to the natural environment.

Stay Always Informed

Join our communities to instantly receive the most important news, reports, and analysis from the aquaculture industry.

This scenario has generated a series of structural changes in the aquaculture industry, where the treatment of water and waste is considered through recirculating systems in closed aquaculture and the reuse of waste as nutrients.

The recirculation and reuse of water is the most classic application of the circular economy in aquaculture. This technique is deployed in several aquaculture systems with “zero effluent” possibilities, whose objective is to maintain stable water quality.

Recirculation systems in aquaculture

Recirculating aquaculture systems (RAS) technology has been developed over the last five decades, and has become more popular and accessible as infrastructure and equipment are commensurately decreasing in price.

RAS has been applied in fattening systems that are extensive in nature (to save water, increase yield and reduce production costs) and intensive systems.

The main objectives of recirculating aquaculture systems are to conserve water and generate less effluents that can harm the surrounding environment.

Biofloc systems

Bioflocs usually form in isolated compartments (tanks or ponds), but unlike the high-tech water purification used in RAS, water recycling occurs directly in the fish production unit, reducing the size and volume of the biofloc. cost of pumps and filtration systems.

The structural and operational advantages of a biofloc system allow culture with high loads of solids suspended in the water, characteristics that affect different species that occur in the RAS, but do not impact omnivorous filter-feeding species such as tilapia and marine shrimp.

Bio-RAS

Bio-RAS is the combination of a recirculation system in aquaculture with biofloc technology.

At present, there is a tendency to merge these two systems of low water demand to optimize crops with a reduction in production costs (especially food and electricity).

The Bio-RAS strategy uses the best and most efficient of each of the technologies, with cost reduction combined with the maximization of technological, zootechnical and animal welfare efficiency with the sustainability of crops.

Partitioned aquaculture systems (PAS)

The partitioned aquaculture system (PAS) was developed in the 1990s in the southern US to culture channel catfish with recirculating effluents.

The aim of the PAS is to not produce effluents, where fish are confined at high densities in concrete tanks (raceways) or smaller ponds, about 5% of the total area for the tank and 95% of the pond for recirculation and the reuse of water.

Partitioned aquaculture systems represent a high degree of intensification with respect to extensive ponds where phytoplankton predominates.

There are two main variations that are becoming common around the world:

to. IPRS for a pond raceway system, and

b. SPs for divided ponds.

Integrated multitrophic aquaculture: aquaponics and fertigation

Integrated multitrophic aquaculture (IMTA) combines the farming of species that require exogenous feeding (for example tilapia and shrimp), with extractive species (filter feeders, grazing) that feed on organic matter (echinoderms, bivalves, micro-crustaceans and worms). and species that extract inorganic substances (phytoplankton, macroalgae and terrestrial plants).

Aquaponics is one of the classic examples of IMTA, where one crop benefits from the by-products of another, thus reducing the need for inputs, nutrients and effluent production.

Conclusion

According to the study authors, the future of tilapia farming is intertwined with urban agriculture and waste fermentation, where low-demand water recirculation systems will be the protagonists of disrupting industries in five main sectors (materials, energy, information, transport and food/health).

The study was funded by the Swedish University of Agricultural Sciences.

Contact

Anders Kiessling,

Department of Animal Nutrition and Management

Swedish University of Agricultural Sciences

P.O. Box 7024, Uppsala 750 07, Sweden.

Email: anders.kiessling@slu.se

Reference (open access):

Zimmermann, S, Kiessling, A, Zhang, J. The future of intensive tilapia production and the circular bioeconomy without effluents: Biofloc technology, recirculation aquaculture systems, bio-RAS, partitioned aquaculture systems and integrated multitrophic aquaculture. Rev Aquac. 2023; 15( Suppl. 1): 22- 31. doi:10.1111/raq.12744

Editor at the digital magazine AquaHoy. He holds a degree in Aquaculture Biology from the National University of Santa (UNS) and a Master’s degree in Science and Innovation Management from the Polytechnic University of Valencia, with postgraduate diplomas in Business Innovation and Innovation Management. He possesses extensive experience in the aquaculture and fisheries sector, having led the Fisheries Innovation Unit of the National Program for Innovation in Fisheries and Aquaculture (PNIPA). He has served as a senior consultant in technology watch, an innovation project formulator and advisor, and a lecturer at UNS. He is a member of the Peruvian College of Biologists and was recognized by the World Aquaculture Society (WAS) in 2016 for his contribution to aquaculture.