Microalgae have established themselves as unicellular organisms of paramount industrial significance. Their unique capacity to produce lipids, carbohydrates, and bioactive compounds renders them an essential raw material for sectors ranging from food and biofuels to bioremediation. In fact, projections indicate that the global market for microalgae-based products is poised to reach $53.43 billion by 2026.

However, scaling the cultivation of these microorganisms presents significant challenges. Biological systems are inherently complex and unpredictable; factors such as light, temperature, pH, and nutrients interact in ways that often elude the control of traditional mathematical models or manual management.

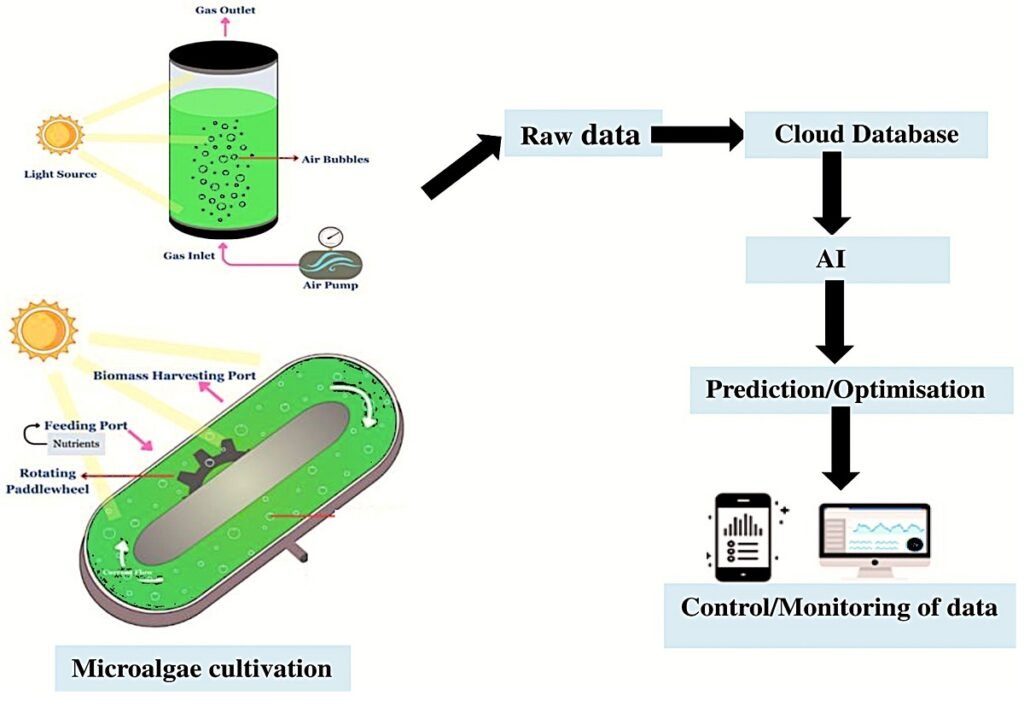

A recent review article published in the journal Processes (2025), conducted by researchers from the Department of Biology at Soonchunhyang University and AlgaeBio, Inc. (South Korea), explores how Artificial Intelligence (AI) and the Internet of Things (IoT) are dismantling these barriers. These technologies not only manage biological complexity but also accelerate process optimization and drastically reduce operational costs.

Key findings

- Superior optimization: AI models outperform traditional mechanistic models in predicting growth and optimal conditions.

- Total automation: IoT integration allows for real-time monitoring and control of critical parameters (light, pH, nutrients) without constant human intervention.

- Yield increase: Specific algorithms have achieved biomass yield increases of up to 90% in certain experimental cultures.

- Cost reduction: It is estimated that AI-based predictive maintenance can reduce operational costs by between 12% and 40%.

- Genomic editing: AI-driven bioinformatics facilitates the identification of genetic targets to improve strains using tools like CRISPR-Cas9.

The challenge of complexity in biosystems

Microalgae cultivation is non-linear. Unlike bacteria or yeast, many microalgae rely on photosynthesis, introducing dynamic variables such as light intensity and day-night cycles. Traditional “trial and error” methods are time-consuming, costly, and rarely achieve biological optima.

This is where AI, specifically Machine Learning (ML), transforms the industry by processing massive volumes of historical and real-time data to identify hidden patterns and predict behaviors.

Core technologies: Beyond theory

The researchers highlight several AI models that are making a difference:

- Artificial Neural Networks (ANN): Inspired by the human brain, these capture complex non-linear relationships. They have been effectively used to classify microalgae genera and predict growth under variable light regimes with greater accuracy than conventional models.

- Genetic Algorithms (GA): These mimic natural selection to “evolve” toward the best solution. A study demonstrated that using GA to optimize the medium for Nannochloropsis gaditana increased eicosapentaenoic acid (EPA) yield by 23%.

- Deep Learning and Computer Vision: Convolutional Neural Networks (CNN) enable non-invasive monitoring, cell counting, and real-time stress detection without destroying samples.

Biomass and lipid optimization: Finding the “Sweet Spot”

One of the most relevant findings is AI’s ability to manage the trade-off between growth and metabolite production. Often, lipid accumulation (for biofuels) requires stressing the culture, which halts growth.

AI identifies the exact balance. For instance, hybrid models have successfully predicted the optimal temperature for Chlorella sp. (29.55°C), obtaining 15% higher biomass productivity compared to controls. Similarly, in Nostoc sp., a hybrid algorithm (CNN-GA) improved biomass yield by an astounding 90%.

The role of IoT and Digital Twins

Digitization requires connected hardware. The Internet of Things (IoT) creates a network of sensors that continuously monitor temperature, turbidity, dissolved oxygen, and pH.

Stay Always Informed

Join our communities to instantly receive the most important news, reports, and analysis from the aquaculture industry.

This interconnection allows for the creation of Digital Twins: virtual replicas of the physical photobioreactor. Fed by real-time data, they allow for the simulation of scenarios and the prediction of results before physical changes are applied, minimizing risks and ensuring optimal conditions.

Sustainability and advanced genomics

Microalgae are potent tools for CO2 capture. Reinforcement learning algorithms dynamically adjust CO2 injection, maximizing carbon fixation and wastewater treatment.

In genomics, AI assists in techniques such as CRISPR-Cas9 by analyzing large datasets to identify which genes to modify, thereby increasing lipid production without affecting cell viability.

Challenges and future perspectives

Despite the progress, limitations exist, primarily regarding data quality and quantity. AI models require large datasets, which are often scarce or inconsistent in this industry. Furthermore, there is the difficulty of generalization: a model for Chlorella may not work for Spirulina.

The proposed solution lies in hybrid models (physics + data) and Transfer Learning, which allows existing models to be adapted to new species with less data.

Conclusion

The review by Rayamajhi and Jung makes it clear that the integration of AI and IoT is not a futuristic option, but a present-day necessity. These technologies allow for a transition from a reactive approach to a predictive and automated one. As sensors become cheaper and algorithms evolve, the “smart microalgae farm” will become the undisputed industry standard.

Reference (open access)

Rayamajhi, V., Hussain, M., Shin, H., & Jung, S. (2025). Recent Advances in the Application of Artificial Intelligence in Microalgal Cultivation. Processes, 13(12), 3764. https://doi.org/10.3390/pr13123764

Editor at the digital magazine AquaHoy. He holds a degree in Aquaculture Biology from the National University of Santa (UNS) and a Master’s degree in Science and Innovation Management from the Polytechnic University of Valencia, with postgraduate diplomas in Business Innovation and Innovation Management. He possesses extensive experience in the aquaculture and fisheries sector, having led the Fisheries Innovation Unit of the National Program for Innovation in Fisheries and Aquaculture (PNIPA). He has served as a senior consultant in technology watch, an innovation project formulator and advisor, and a lecturer at UNS. He is a member of the Peruvian College of Biologists and was recognized by the World Aquaculture Society (WAS) in 2016 for his contribution to aquaculture.