Microalgae constitute the cornerstone for a vast array of high-value products, ranging from aquaculture feed and nutraceuticals to advanced applications in biotechnology and carbon sequestration. However, the commercial viability of these cultures hinges upon rigorous environmental control and, crucially, constant monitoring of cell health, growth rates, and biomass productivity.

Historically, the bedrock of this monitoring has been cell enumeration and measurement—processes that have relied for decades on labor-intensive manual methods utilizing microscopes, hemocytometers, and settling chambers. While automated alternatives such as Coulter counters or flow cytometry exist, these instruments often present prohibitive costs for smaller laboratories and technical limitations when handling large or chain-forming cells.

In response to this techno-economic challenge, researchers from SINTEF Industry, UiT The Arctic University of Norway, and the Cawthron Institute in New Zealand have developed and validated “Algalytics.” This novel web application integrates image processing and Convolutional Neural Networks (CNN) to automate microalgae analysis from archived microscope images. The findings of this development have been published in the scientific journal Algal Research.

- 1 Key Study Conclusions

- 2 The Traditional Monitoring Bottleneck

- 3 How Does Algalytics Work? AI at the Service of the Laboratory

- 4 Validation: From Large Diatoms to Small Haptophytes

- 5 Precision Results and the “Halo Effect” Challenge

- 6 Implications for the Future of Aquaculture

- 7 Entradas relacionadas:

Key Study Conclusions

- High Enumeration Accuracy: The application demonstrated accuracy exceeding 96%, validated across both large and small species.

- Accessibility and Cost-Effectiveness: Algalytics presents itself as a scalable alternative to costly cytometry, requiring only standard microscope images.

- Robustness Regarding Image Quality: Thanks to advanced preprocessing algorithms, the system operates effectively even with out-of-focus images or varying densities.

- Measurement Correction: An optical “Halo Effect” was identified that overestimates cell size; this is correctable via calibration.

- Data Efficiency: The AI can be trained and function correctly with limited datasets, facilitating adaptation to new species.

The Traditional Monitoring Bottleneck

Precise monitoring is vital for both research and industrial scaling. Culture quality directly impacts the consistency of the final product. However, the traditional microscopy-based method is labor-intensive, time-consuming, and prone to human error, varying significantly between operators.

Conversely, existing automation presented entry barriers. High-end systems may fail in dense cultures where cells overlap, causing segmentation errors. Algalytics was created to bridge this gap, providing precise metrics with minimal operator training.

How Does Algalytics Work? AI at the Service of the Laboratory

The web application operates via a sophisticated backend architecture fusing classical image processing with Deep Learning. The workflow consists of five stages:

- Upload and Resizing: The user uploads the raw image obtained from the microscope camera.

- Image Processing: Sharpening algorithms, edge detection (Canny), and “Watershed” transformation are applied to separate agglomerated cells.

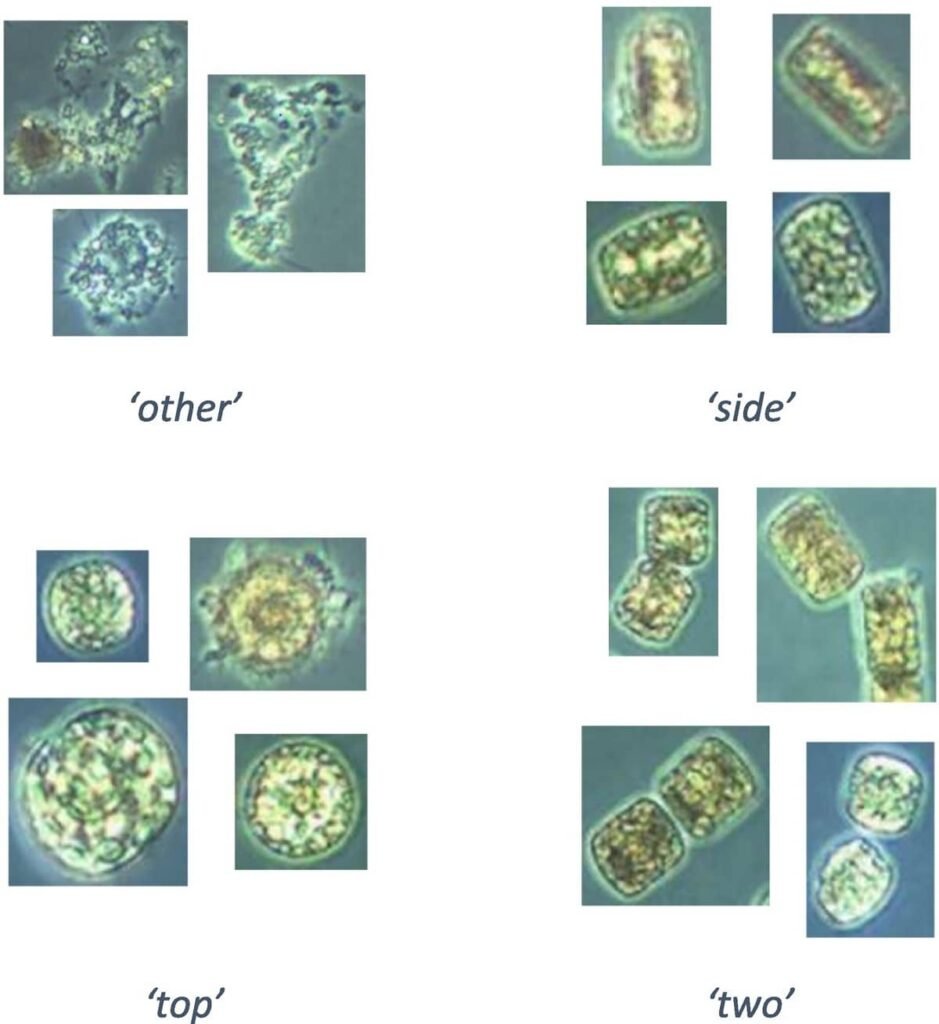

- Object Classification: A pre-trained neural network (VGGNet architecture) classifies contours into categories such as ‘side view,’ ‘top view,’ or ‘two cells.’

- Measurement: Computational geometry calculates the diameter and height of viable algae.

- Statistical Analysis: Automatic generation of size distributions, averages, and biomass calculations.

Validation: From Large Diatoms to Small Haptophytes

To ensure the tool’s versatility, researchers validated it with two systems of commercial importance:

- Porosira glacialis: A large centric diatom cultivated for CO2 sequestration and biomass production at the Finnfjord AS plant (Norway). Its complex morphology served to develop the detailed methodology.

- Tisochrysis lutea: A small flagellated haptophyte commonly used in larval feed. Samples from the Cawthron Institute (New Zealand) allowed for verification of the approach’s robustness with limited data.

Precision Results and the “Halo Effect” Challenge

Results confirmed the application’s high effectiveness. In tests with P. glacialis, comparison with the “ground truth” (actual manual count) yielded a coefficient of determination (R2) of 0.987, indicating a nearly perfect correlation. Even when training the AI with only 12.5% of the original images, accuracy remained robust (R2 > 0.96$).

For the species T. lutea, the model achieved 97.72% precision in test subsets, correctly identifying 238 algae in a dense image versus a manual count of 236.

Stay Always Informed

Join our communities to instantly receive the most important news, reports, and analysis from the aquaculture industry.

However, automatic size measurement presented challenges. A tendency towards overestimation was detected due to two factors: imperfect digital box alignment and, more critically, the “Halo Effect.” This optical artifact, caused by light scattering or phase contrast, systematically added about 5 micrometers to the detected size. After applying calibration correction, measurements aligned with laboratory data.

Implications for the Future of Aquaculture

The introduction of tools like Algalytics marks a milestone in the digitization of aquaculture. Automating monoculture monitoring allows for consistent data by eliminating subjectivity, reducing routine task times, and detecting issues like contamination or cell death phases early.

The authors suggest that future iterations could integrate the recognition of complex algal chains and connect to the cloud for fully automated workflows, extending its utility even to sediment analysis in aquaculture.

Contact

Elena-Roxana Popescu

SINTEF Industry

Postboks 4760 Torgarden, N-7465 Trondheim, Norway

Email: Elena-Roxana.Popescu@sintef.no

Reference (open access)

Popescu, E., Einbu, A., Israelsen, L., Eriksen, G., Hardy, N., Ingebrigtsen, R. A., & Pettersen, T. (2025). Web application for automated counting and size analysis of industrial microalgae monocultures using image processing and Convolutional Neural Network based deep learning. Algal Research, 90, 104173. https://doi.org/10.1016/j.algal.2025.104173

Editor at the digital magazine AquaHoy. He holds a degree in Aquaculture Biology from the National University of Santa (UNS) and a Master’s degree in Science and Innovation Management from the Polytechnic University of Valencia, with postgraduate diplomas in Business Innovation and Innovation Management. He possesses extensive experience in the aquaculture and fisheries sector, having led the Fisheries Innovation Unit of the National Program for Innovation in Fisheries and Aquaculture (PNIPA). He has served as a senior consultant in technology watch, an innovation project formulator and advisor, and a lecturer at UNS. He is a member of the Peruvian College of Biologists and was recognized by the World Aquaculture Society (WAS) in 2016 for his contribution to aquaculture.