Modern aquaculture faces constant pressure: how to achieve sustainable growth. For decades, the industry has relied on fishmeal and soybean meal as its primary protein sources. However, this dependency is increasingly problematic due to rising costs, limited availability, and pressing sustainability concerns.

The obvious answer has been to look toward alternatives, primarily cheaper plant-based ingredients. But these bring their own set of challenges: anti-nutritional factors (ANFs). Compounds such as phytic acid, tannins, and trypsin inhibitors interfere with nutrient digestion and absorption in fish and shrimp.

This is where biotechnology offers a promising solution: Solid-State Fermentation (SSF). A recent review article published in Frontiers in Marine Science by scientists from Tamil Nadu Dr. J. Jayalalithaa Fisheries University, Guru Angad Dev Veterinary and Animal Sciences University, Maharashtra Animal and Fishery Science University, the Indian Council of Agriculture and Research (ICAR), Andhra Pradesh Fisheries University, and Central Agricultural University explores how this technology could be the key to unlocking the true potential of alternative ingredients and building a more sustainable future for aquafeeds.

Key takeaways

- 1 Key takeaways

- 2 What exactly is Solid-State Fermentation (SSF)?

- 3 The key benefits of SSF for aquaculture nutrition

- 4 A driver for gut health and immunity

- 5 SSF vs. Submerged Fermentation (SmF): The sustainable advantage

- 6 Challenges and limitations: Not everything is perfect

- 7 Conclusion: The verdict on SSF

- 8 Entradas relacionadas:

- Solid-State Fermentation (SSF) utilizes microbes to effectively break down anti-nutritional factors (ANFs) in plant-based ingredients, such as phytic acid and tannins.

- The process increases digestibility, protein content (via microbial biomass), and nutrient bioavailability in low-value by-products.

- SSF enriches the feed with bioactive compounds, organic acids, and enzymes that promote healthy gut microbiota and enhance the immune response in fish.

- Unlike other methods, SSF requires less energy, generates minimal liquid waste, and valorizes agro-industrial by-products, aligning with the circular bioeconomy.

- Despite its advantages, industrial scale-up, precise heat and moisture control, and the risk of nutrient loss (such as certain amino acids) remain key obstacles.

What exactly is Solid-State Fermentation (SSF)?

Unlike Submerged Fermentation (SmF), which occurs in a liquid medium, SSF is a process that cultivates microorganisms on a solid substrate under low-moisture conditions, generally between 40% and 60%.

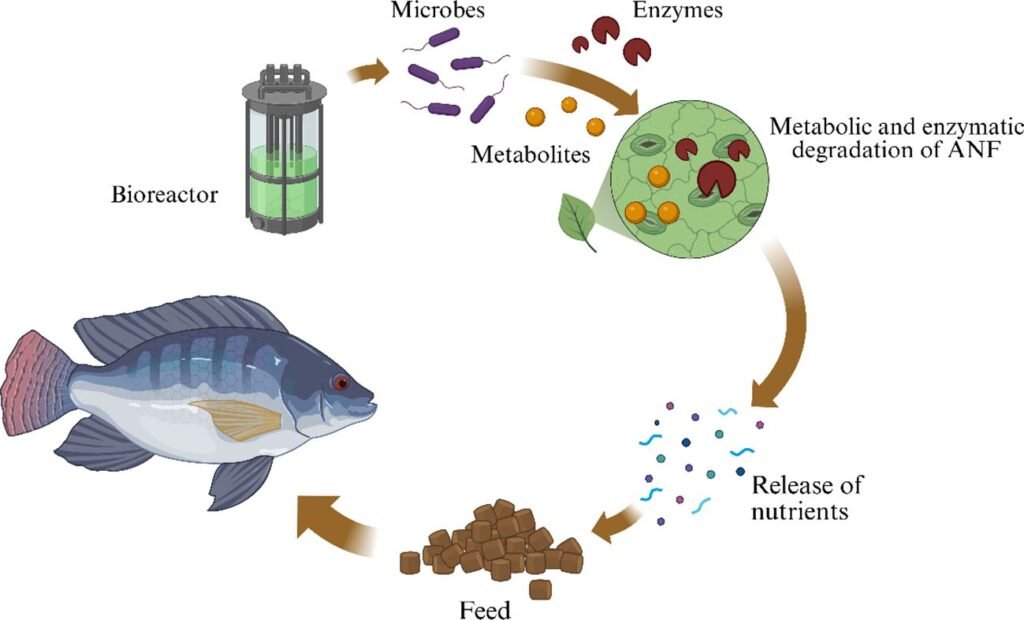

In essence, SSF mimics the natural decomposition process. Low-value agro-industrial by-products—such as rice bran, cassava peel, middlings, or bagasse—are taken and inoculated with specific microorganisms.

These microbes, which can be fungi (like Aspergillus niger or Rhizopus oligosporus), yeasts (Saccharomyces cerevisiae), or bacteria (Bacillus subtilis or Lactobacillus spp.), do the heavy lifting. They grow on the substrate, consuming complex carbohydrates and, in the process, transform the material into a high-value nutritional ingredient.

The key benefits of SSF for aquaculture nutrition

The analysis highlights that SSF is not just a way to use waste; it is a nutritional “upgrading” process with multiple benefits for the animal.

Stay Always Informed

Join our communities to instantly receive the most important news, reports, and analysis from the aquaculture industry.

The “Superpower” against Anti-Nutritional Factors (ANFs)

This is perhaps the most critical benefit of SSF. The microbes used secrete a potent cocktail of extracellular enzymes.

For example, they produce phytases that degrade phytic acid (improving mineral absorption), tannases that neutralize tannins, and proteases that break down trypsin inhibitors. By drastically reducing these ANFs, SSF converts previously problematic plant-based ingredients into highly digestible feedstuffs.

Improved nutritional profile and digestibility

SSF enriches ingredients in several ways:

- Protein increase: As the microbes (fungi, yeast) grow, their own protein-rich biomass is added to the substrate, increasing the total crude protein content.

- Fiber breakdown: Enzymes like cellulase and xylanase, produced by fungi, break down crude fiber and non-starch polysaccharides (NSPs), releasing nutrients that were previously “trapped” within plant cell walls.

- Amino Acid enhancement: Although strain-dependent, SSF can increase the availability of essential amino acids.

A driver for gut health and immunity

The benefits of SSF extend beyond simple nutrition; they act as a functional factor for fish health.

The process not only reduces ANFs but also generates beneficial bioactive compounds, such as organic acids, peptides, and antioxidants. These metabolites, along with the microbes themselves (used as probiotics), have a direct impact on the animal’s gut.

Studies cited in the review show that fermented feeds can:

- Modulate the microbiota: Promote the growth of beneficial bacteria, such as lactic acid bacteria (LAB), and reduce the presence of pathogens.

- Improve intestinal morphology: Diets with SSF have been observed to increase intestinal villi height, which means a larger surface area for nutrient absorption.

- Boost immunity: Fermented ingredients can stimulate the non-specific immune response, improving disease resistance.

SSF vs. Submerged Fermentation (SmF): The sustainable advantage

The review also compares SSF with Submerged Fermentation (SmF), the more traditional method using liquid substrates.

SSF demonstrates significant advantages in sustainability and cost:

- Less Water: By operating with low moisture, water use is minimal, and critically, it produces very little to no wastewater.

- Less Energy: It requires less energy for operation and for post-processing (like drying) compared to the large liquid volume of SmF.

- Lower Contamination: The low water content makes the substrate less prone to bacterial contamination.

- Higher Yield: Higher product concentrations are often obtained.

For these reasons, SSF is considered a more robust, eco-friendly, and cost-effective technology for the feed industry.

Challenges and limitations: Not everything is perfect

Despite its enormous potential, SSF is not without its challenges, and the review is clear about the obstacles hindering its mass adoption.

- Process control: The solid nature of the substrate makes it difficult to control key parameters uniformly. Heat generated by the microbes can accumulate in the center, inhibiting growth. Maintaining optimal moisture and pH throughout the batch is complex.

- Scalability: What works well in a lab is logistically complicated to replicate at an industrial scale. Designing large, efficient bioreactors that allow for proper mixing and aeration remains the primary engineering challenge.

- Safety: If not managed properly, there is a risk of the wrong microbes growing. Specifically, some filamentous fungi can produce dangerous mycotoxins.

- Nutrient loss: This is an important counterpoint. While SSF often enriches protein, some studies have reported that certain microbes may consume essential amino acids (like lysine, methionine, and cysteine) or lipids during the process, decreasing the nutritional value. Strain selection and fermentation conditions are crucial to prevent this.

Conclusion: The verdict on SSF

Solid-State Fermentation emerges as a powerful biotechnological tool for aquaculture. It is much more than a simple waste management technique; it is a “valorization” process that transforms low-cost agro-industrial by-products into high-nutrition, functional ingredients.

By directly addressing the ANF problem, SSF opens the door for the industry to reduce its dependency on fishmeal and soy, improving sustainability and profitability. Its proven benefits for digestibility, gut health, and immunity position it as a key technology for the future of aquafeeds.

However, for this future to materialize, research must focus on overcoming scalability and engineering challenges, optimizing microbial strains (perhaps through genetic engineering), and standardizing safety protocols to ensure a consistent and safe final product.

Contact

Pandi Kalaiselvan

Dr. MGR Fisheries College and Research Institute, Tamil Nadu Dr. J. Jayalalithaa Fisheries University

Thalainayeru, Tamil Nadu, India

Email: kalaiprs1641@gmail.com

Reference (open access)

Kalaiselvan, P., Devi, N. C., Deepti, M., Devi, A. A., Akamad, K., Dheeran, P., Debbarma, S., Vadivel, D., & Rajesh, D. (2025). Solid-state fermentation—A sustainable future technology in aquafeeds? Frontiers in Marine Science, 12, 1669719. https://doi.org/10.3389/fmars.2025.1669719

Editor at the digital magazine AquaHoy. He holds a degree in Aquaculture Biology from the National University of Santa (UNS) and a Master’s degree in Science and Innovation Management from the Polytechnic University of Valencia, with postgraduate diplomas in Business Innovation and Innovation Management. He possesses extensive experience in the aquaculture and fisheries sector, having led the Fisheries Innovation Unit of the National Program for Innovation in Fisheries and Aquaculture (PNIPA). He has served as a senior consultant in technology watch, an innovation project formulator and advisor, and a lecturer at UNS. He is a member of the Peruvian College of Biologists and was recognized by the World Aquaculture Society (WAS) in 2016 for his contribution to aquaculture.