Our dependency on fossil fuels is decreasing, prompting a global quest for cleaner, renewable alternatives. Biofuels, such as biodiesel, have become a beacon of hope. However, traditional feedstocks for biodiesel production compete with food resources; in this regard, microalgae emerge as a significant alternative.

Biodiesel production is classified based on the feedstock used. First-generation biofuels rely on food sources like edible plants and seeds, raising concerns about food production competition. Second-generation options utilize non-edible plants, animal fats, and used cooking oils, offering a more sustainable approach.

However, the future lies in third-generation biofuels: algae. Microalgae, in particular, are microscopic powerhouses with immense potential. A team of scientists from the Manipal Institute of Technology at the Manipal Academy of Higher Education published a scientific review to explain the difference between direct and indirect transesterification processes; likewise, the document clarifies the roles of catalysts in the transesterification process and FAME production. Additionally, it analyzes the costs and challenges associated with each step of biodiesel production from microalgae.

Microalgae: Tiny Titans of Biofuel Production

Microalgae are microscopic marvels: single-celled organisms that harness sunlight to produce energy. Unlike terrestrial plants, they boast exceptional photosynthetic efficiency, converting sunlight into energy at a much faster rate.

The primary strength of microalgae lies in their ability to accumulate large amounts of neutral lipids, the basic components of biodiesel.

Factors Affecting Biodiesel Yield

Biodiesel, a clean-burning fuel derived from renewable sources, can significantly reduce dependence on fossil fuels. The success of microalgae-based biodiesel production depends on two crucial factors:

- Biomass availability: Cultivation conditions significantly impact the growth rate and overall biomass of microalgae. Factors such as light intensity, temperature, pH balance, and nutrient availability influence this. Optimizing these parameters is essential to maximize microalgae biomass.

- Lipid content: Different microalgae species have varying lipid accumulation capacities. Scientists are constantly seeking and developing strains with superior lipid production capabilities.

Cultivating Green Gold

Microalgae cultivation for biodiesel production requires careful optimization of various factors:

- Growth parameters: Temperature, light intensity, pH, and nutrient availability play a crucial role in microalgae growth and lipid production.

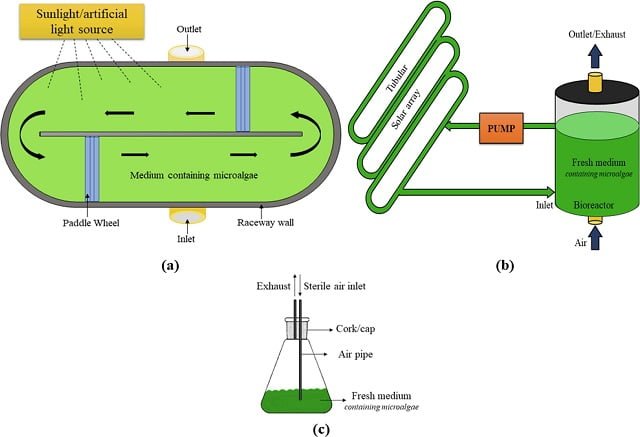

- Cultivation methods: Open ponds, closed photobioreactors, and other cultivation techniques have their advantages and disadvantages in terms of scalability and efficiency.

From Microalgae to Biodiesel: Processing Power

Once we have robust microalgae biomass with high lipid content, it’s time to transform it into biodiesel. Here’s a breakdown of the key steps:

- Lipid extraction: Various methods exist to extract lipids from microalgae. The choice depends on factors like efficiency, cost, and environmental impact.

- Transesterification: This crucial process converts the extracted lipids into biodiesel (fatty acid methyl esters or FAME). There are two main approaches:

- Direct transesterification: This method directly converts whole algal cells into biodiesel, eliminating the need for separate lipid extraction. However, it may be less efficient and require specialized catalysts.

- Indirect transesterification: Here, lipids are first extracted from microalgae and then converted into biodiesel. This method offers better control over the process but adds step.

- Catalyst function: Both methods rely on catalysts to accelerate the transesterification reaction. The choice and effectiveness of the catalyst significantly impact biodiesel yield and quality.

Challenges and the Road Ahead

While microalgae-based biodiesel is highly promising, there are hurdles to overcome:

- Cost-effectiveness: Scaling up production to meet commercial demands remains a challenge. Optimizing cultivation, harvesting, and processing methods is crucial to reducing costs.

- Energy efficiency: The entire process, from cultivation to conversion, must be energy-efficient to ensure true sustainability.

Conclusion

Microalgae offer a vision of a future driven by renewable and sustainable biofuels. By addressing current challenges and continually innovating, we can unlock the full potential of these tiny titans and usher in a greener tomorrow.

Contact

Ramesh Vinayagam

Department of Chemical Engineering, Manipal Institute of Technology, Manipal Academy of Higher Education, Manipal 576104, Karnataka, India

Email: ramesh.v@manipal.edu

Reference (open access)

Pandey, S., Narayanan, I., Selvaraj, R., Varadavenkatesan, T., & Vinayagam, R. (2024). Biodiesel production from microalgae: A comprehensive review on influential factors, transesterification processes, and challenges. Fuel, 367, 131547. https://doi.org/10.1016/j.fuel.2024.131547

Editor at the digital magazine AquaHoy. He holds a degree in Aquaculture Biology from the National University of Santa (UNS) and a Master’s degree in Science and Innovation Management from the Polytechnic University of Valencia, with postgraduate diplomas in Business Innovation and Innovation Management. He possesses extensive experience in the aquaculture and fisheries sector, having led the Fisheries Innovation Unit of the National Program for Innovation in Fisheries and Aquaculture (PNIPA). He has served as a senior consultant in technology watch, an innovation project formulator and advisor, and a lecturer at UNS. He is a member of the Peruvian College of Biologists and was recognized by the World Aquaculture Society (WAS) in 2016 for his contribution to aquaculture.