Maintaining the premium quality of Atlantic salmon (Salmo salar) from the farm to the consumer’s table is a considerable logistical challenge, especially when freezing is necessary. While traditional freezing extends shelf life, it often degrades product quality by causing damage from large ice crystals, protein denaturation, and moisture loss.

A recent study in Food Chemistry by researchers from Ningbo University and Iwate University explores an innovative solution: combining liquid immersion freezing (LIF) with a static magnetic field (SMF). The results demonstrate that this synergistic technique, named SMF-LIF, not only dramatically accelerates the process but also exceptionally protects the integrity of the salmon muscle.

Key findings

- Static magnetic field-assisted liquid immersion freezing (SMF-LIF) is the fastest and most efficient method, freezing salmon in just 4.1 minutes compared to 151.5 minutes in a conventional refrigerator.

- This technology drastically reduces the size of ice crystals (69 µm vs. 205 µm), minimizing mechanical damage to muscle fibers.

- Salmon frozen with SMF-LIF exhibits lower drip loss (12.92%), resulting in a juicier product with greater weight after thawing.

- The muscle quality is superior, showing significantly higher hardness (1280.01 g) and better preservation of protein structure, which is crucial for the final texture.

The problem of ice crystals in traditional freezing

When fish is frozen slowly, as in a conventional freezer (refrigerator freezing, RF), the water within the muscle has time to migrate and form large ice crystals, primarily in the extracellular space. These crystals act like microscopic blades that puncture and tear cell membranes and muscle fibers. Upon thawing, these damaged structures are unable to retain water, leading to significant liquid loss (drip or exudate) along with valuable nutrients, thereby affecting texture, flavor, and economic yield.

Four methods tested: Which best preserves salmon?

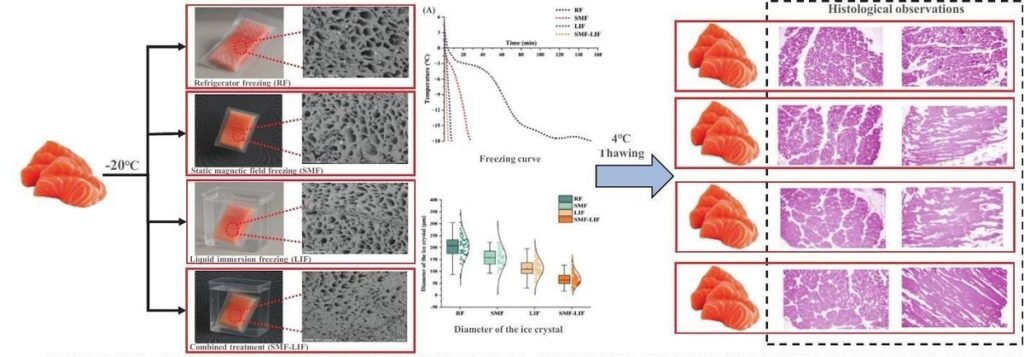

To find the best alternative, the researchers compared four different freezing methods applied to Atlantic salmon muscle samples:

- Refrigerator Freezing (RF): The conventional method, in a freezer at -20°C.

- Liquid Immersion Freezing (LIF): Immersing the samples in ethanol at -20°C, which transfers cold much faster than air.

- Static Magnetic Field Freezing (SMF): Using a device that applies a 5 mT magnetic field during freezing at -20°C.

- Combined Freezing (SMF-LIF): The simultaneous application of liquid immersion and the static magnetic field.

Ultra-fast freezing that protects muscle

The findings revealed the clear superiority of the combined SMF-LIF method in every evaluated aspect.

Freezing speed and ice formation

The difference in speed was astonishing. While the RF method took 151.5 minutes to completely freeze the sample, the SMF-LIF method achieved this in just 4.1 minutes. This speed is crucial because it shortens the time the product spends in the “zone of maximum ice crystal formation” (between -1.5 and -4°C), preventing the crystals from growing large.

Electron microscopy analysis confirmed this advantage: RF samples showed large, irregular cavities (left by crystals 205 µm in diameter), indicative of severe structural damage. In contrast, the SMF-LIF method produced a honeycomb-like microstructure with tiny, uniform pores (from crystals of only 69 µm), preserving the integrity of the muscle fibers.

Less loss, more juiciness, and better texture

The direct consequence of a better microstructure is a greater water-holding capacity. The SMF-LIF group recorded the lowest thawing, centrifugation, and cooking losses. For instance, centrifugation loss was only 12.92% in SMF-LIF samples, compared to 18.68% with the conventional method. This means the final product is juicier, maintains its weight better, and retains its water-soluble nutrients.

These benefits were reflected in the texture profile analysis. Salmon frozen with SMF-LIF was significantly firmer, more elastic, and more cohesive than traditionally frozen salmon. Hardness, a key quality indicator, reached 1208.01 g in the SMF-LIF group—more than double the 511.61 g of the RF group.

Stay Always Informed

Join our communities to instantly receive the most important news, reports, and analysis from the aquaculture industry.

Protection at the molecular level: The key lies in proteins

Freezing damage is not just physical. It also affects the structure of myofibrillar proteins, which are fundamental to the muscle’s texture and water-holding capacity. Researchers measured the activity of Ca²⁺-ATPase, an enzyme whose activity reflects the integrity of myosin, a key protein. The SMF-LIF method maintained enzymatic activity at 0.31 U/mg, well above the RF samples (0.20 U/mg), indicating less protein denaturation.

Furthermore, analysis of the protein secondary structure showed that salmon frozen with SMF-LIF retained a higher content of α-helices (23.91%), an organized and stable structure. This contrasted with the low content (15.57%) in RF samples, which exhibited more “random coils,” a disordered form associated with denaturation.

How does the magnetic-liquid synergy work?

The success of the SMF-LIF technology lies in a dual mechanism of action:

- External (Liquid Immersion): Ethanol, having a much higher thermal conductivity than air, extracts heat from the fish’s surface extremely quickly.

- Internal (Magnetic Field): The 5 mT magnetic field acts on water molecules, which are dipoles. It aligns them, weakens the hydrogen bonds, and facilitates a more uniform and rapid nucleation of ice crystals, preventing their uncontrolled growth.

The combination of accelerated surface cooling and molecular control of water crystallization results in ultra-fast, homogeneous freezing that protects the salmon’s quality at every level.

Implications for the salmon industry

The results of this study suggest that magnetic field-assisted immersion freezing technology is a promising alternative for the fish processing industry. By minimizing cellular damage and protein denaturation, this technique makes it possible to obtain a frozen product with a quality very close to that of a fresh product.

The adoption of this method could translate into tangible benefits for producers and processors, such as reduced drip losses, improved sensory quality of the final product, and consequently, greater consumer acceptance and valuation. Although further research is needed for its implementation on an industrial scale, SMF-LIF is emerging as a key tool for the future of the cold chain in aquaculture.

Contact

Huamao Wei

College of Food Science and Engineering, Ningbo University

Ningbo 315211, China.

Email: whm900916@163.com

Reference (open access)

Liu, X., Yuan, C., Ou, C., Huang, T., Lu, X., Yang, W., Lou, Y., & Wei, H. (2025). A comparative study of freezing methods on quality of Atlantic Salmon: Refrigerator, liquid immersion, and magnetic field-assisted techniques. Food Chemistry, 493, 145818. https://doi.org/10.1016/j.foodchem.2025.145818

Editor at the digital magazine AquaHoy. He holds a degree in Aquaculture Biology from the National University of Santa (UNS) and a Master’s degree in Science and Innovation Management from the Polytechnic University of Valencia, with postgraduate diplomas in Business Innovation and Innovation Management. He possesses extensive experience in the aquaculture and fisheries sector, having led the Fisheries Innovation Unit of the National Program for Innovation in Fisheries and Aquaculture (PNIPA). He has served as a senior consultant in technology watch, an innovation project formulator and advisor, and a lecturer at UNS. He is a member of the Peruvian College of Biologists and was recognized by the World Aquaculture Society (WAS) in 2016 for his contribution to aquaculture.