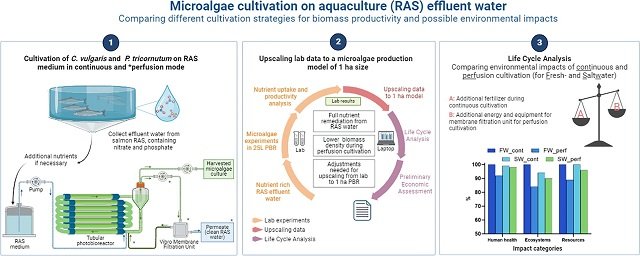

Aquaculture recirculation systems (RAS) offer a more sustainable solution by recirculating water, but they still produce nutrient-rich effluents. A promising approach to addressing this challenge lies in harnessing the power of microalgae. These microscopic organisms are natural filters capable of effectively removing excess nutrients from wastewater.

A team of researchers from NORCE Norwegian Research Centre AS, VHL University of Applied Sciences, Wageningen University and Research, and the University of Bergen has developed an innovative biofilm reactor system to cultivate microalgae using RAS effluent water.

Biofilm Reactors: A Novel Approach

Biofilm reactors provide a unique platform for large-scale microalgae cultivation. In these reactors, microalgae form biofilms that adhere to a solid surface, creating a complex microbial community. Biofilm reactors offer several advantages over traditional suspended culture systems, including:

- High nutrient removal efficiency: Biofilms provide a large surface area for nutrient uptake, enabling efficient nutrient removal from wastewater.

- Reduced contamination risk: The closed nature of biofilm reactors minimizes the risk of contamination by other microorganisms.

- Simplified harvesting: Microalgae biomass can be easily harvested from the biofilm surface, reducing the need for complex collection processes.

- Adaptability to variable nutrient concentrations: Biofilm reactors can handle fluctuations in nutrient concentrations, making them suitable for aquaculture wastewater treatment.

A Nature-Inspired Solution

The study focused on two microalgae species, Chlorella vulgaris and Phaeodactylum tricornutum, cultivated in a dual-layer biofilm reactor.

The biofilm reactor is designed to mimic natural ecosystems, creating a favorable environment for microalgae growth. It consists of two layers: a substrate distribution layer and a carrier layer for biofilm cultivation.

The carrier material plays a crucial role in supporting the adhesion and growth of microalgae. Researchers tested five different carrier materials to evaluate their suitability for promoting microalgae adhesion.

After extensive testing, the researchers identified viscose fiber as the most suitable carrier material. This material provides a stable surface for biofilm formation and promotes efficient nutrient uptake.

However, the biofilm reactor design needed improvements to adapt to the suitability of saltwater. Water evaporation led to changes in salinity and nutrient concentrations, causing salt crust formation on the biofilm and clogging the irrigation system. To address this, researchers diluted the medium with osmotic water to compensate for evaporation and implemented technical improvements to the irrigation system, establishing stable cultivation conditions.

Microalgae for Nutrient Removal and Biomass Production

The biofilm reactor was tested with three different water types: freshwater, brackish water, and saltwater, commonly discharged during a salmon RAS production cycle. Researchers inoculated the carrier material with microalgae paste and harvested the biofilm every three days.

Stay Always Informed

Join our communities to instantly receive the most important news, reports, and analysis from the aquaculture industry.

The results were impressive.

The biofilm reactor demonstrated a remarkable capacity to completely remove nitrate and phosphate from RAS effluent water. Additionally, it showed resilience to fluctuations in nutrient concentrations and salinity.

In terms of biomass productivity, Phaeodactylum tricornutum cultivated in brackish RAS medium was the top performer, achieving a productivity of 15.28 g m⁻² d⁻¹.

Meanwhile, Chlorella vulgaris grown in freshwater RAS medium and Phaeodactylum tricornutum in saltwater RAS medium yielded lower biomass productivities of 4.25 g m⁻² d⁻¹ and 4.35 g m⁻² d⁻¹, respectively.

Implications for RAS

The study demonstrates the potential of microalgae-based biofilm reactors to purify RAS effluent water, reducing the environmental impact of salmon production. The findings also highlight the importance of optimizing the biofilm reactor’s design and operation to meet the specific requirements of different water types and microalgae species.

Conclusion

By integrating microalgae biofilm reactors into RAS, it is possible to achieve truly sustainable aquaculture operations. Nutrient-rich wastewater can be effectively treated, reducing environmental impact and generating valuable biomass as a byproduct. This biomass can be further processed into a variety of products, such as biofuels, animal feed, and high-value compounds.

The study was funded by the Norwegian Research Council.

Contact

Hanna Böpple

NORCE Norwegian Research Centre AS, Norway

Email: habp@norceresearch.no

Reference (open access)

Böpple, H., Kymmell, N. L., Slegers, P. M., Breuhaus, P., & Kleinegris, D. M. (2024). Water treatment of recirculating aquaculture system (RAS) effluent water through microalgal biofilms. Algal Research, 84, 103798. https://doi.org/10.1016/j.algal.2024.103798

Editor at the digital magazine AquaHoy. He holds a degree in Aquaculture Biology from the National University of Santa (UNS) and a Master’s degree in Science and Innovation Management from the Polytechnic University of Valencia, with postgraduate diplomas in Business Innovation and Innovation Management. He possesses extensive experience in the aquaculture and fisheries sector, having led the Fisheries Innovation Unit of the National Program for Innovation in Fisheries and Aquaculture (PNIPA). He has served as a senior consultant in technology watch, an innovation project formulator and advisor, and a lecturer at UNS. He is a member of the Peruvian College of Biologists and was recognized by the World Aquaculture Society (WAS) in 2016 for his contribution to aquaculture.