As the global population continues to grow, so does the demand for protein-rich foods. Traditional protein sources, such as meat and dairy products, are under increasing pressure due to environmental concerns and resource limitations. This has led to growing interest in alternative protein sources, including plant-based options and those derived from marine organisms.

Sea lettuce protein (Ulva fenestrata) is a promising complement to both meat and other current alternative protein sources. Seaweed also contains many other important nutrients and is cultivated without the need for irrigation, fertilization, or pesticide spraying. However, traditional methods for extracting proteins from seaweed have often been inefficient due to the tightly bound nature of these proteins, leaving their full potential untapped in our diets.

A recent study published by scientists at Chalmers University of Technology has demonstrated a new method for extracting proteins from seaweed, specifically from the species Ulva fenestrata. They discovered a novel way to extract these proteins with three times the efficiency of previous methods, paving the way for seaweed burgers and protein shakes from the ocean.

The Extraction Method

The study used a new extraction method involving the processing of U. fenestrata with an aqueous solution of 0.1-0.5% Triton X-114, followed by reprocessing the pellet with an alkaline aqueous solution. The solubilized proteins were then precipitated by acidification. This method resulted in a 3.4-fold increase in protein extraction, measured as total amino acids, compared to the control with two cycles of alkaline aqueous extraction.

“It has an umami taste with a certain saltiness, even though it does not contain high levels of salt. I’d say it’s a great flavor enhancer for seafood dishes and products, but the possibilities are endless. Why not protein shakes or ‘blue burgers’ from the sea?” says João Trigo, PhD in Food Science at Chalmers, about the dark green powder produced by the process, which is a sea lettuce protein concentrate.

The Role of Triton

Triton X-114, a non-ionic detergent, played a crucial role in the extraction method. It disrupted chloroplasts and likely solubilized lipophilic membrane proteins, as supported by microstructural analysis and the polypeptide pattern. The protein extracts derived from Triton contained lipids within the precipitates/aggregates and were richer in fatty acids typical of photosynthetic membranes.

Benefits of Seaweed Protein

Seaweed protein offers several advantages over traditional protein sources:

- Sustainability: Seaweed cultivation has minimal environmental impact and can be grown in coastal areas without competing with land-based agriculture.

- Nutritional Value: Seaweed is rich in essential amino acids, vitamins, and minerals, making it a highly nutritious food source.

- Functional Properties: Seaweed proteins have unique functional properties, such as emulsification and gelation, that can be utilized in food processing.

The CirkAlg Project

The CirkAlg project, led by Chalmers University of Technology, has explored the potential of developing processes to create a new “blue-green” food industry in Sweden, utilizing seaweed as a promising protein source.

As part of the project, a scientific study recently published in Food Chemistry demonstrates a unique way to extract proteins from sea lettuce, enabling three times more protein extraction from seaweed than was possible with previous methods.

Stay Always Informed

Join our communities to instantly receive the most important news, reports, and analysis from the aquaculture industry.

“Our method is a major step forward, bringing us closer to making the extraction of these proteins more affordable, something that is already being done with pea and soy proteins,” says João Trigo.

Contains Several Essential Nutrients

In addition to essential proteins, sea lettuce contains other highly valuable nutrients for humans, such as vitamin B12 and the same type of omega-3 fatty acids found in fatty fish like salmon. People who do not consume animal products are at risk of developing a vitamin B12 deficiency, which is necessary for the body to form red blood cells, among other functions.

Moreover, cultivating sea lettuce has several advantages compared to land-grown proteins, such as the fact that seaweed does not need to be irrigated, fertilized, or sprayed with pesticides. Sea lettuce is also hardy and grows well under various conditions, such as different salinities and nitrogen availability.

“Humanity will need to find and combine a much more diverse intake of protein sources than what is currently available in our diets to meet sustainability and nutritional requirements. Seaweed is a great complement to many products already on the market. We need all these solutions, and marine possibilities—the so-called blue proteins—have been overlooked so far,” says Ingrid Undeland, Professor of Food Science at Chalmers and coordinator of CirkAlg.

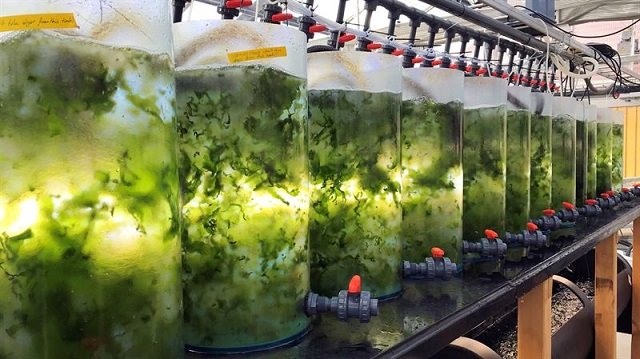

In addition to the newly published extraction method, Chalmers researchers are collaborating with the University of Gothenburg to increase the actual protein content in seaweed. By cultivating sea lettuce in processed water from the fishing industry, the protein content can be significantly increased while nutrients that would otherwise be lost are redistributed within the food chain. At the Tjärnö Marine Laboratory (part of the University of Gothenburg) in northern Bohuslän, Sweden, a large number of successful cultivation experiments have been conducted within the CirkAlg project, based on industrial water streams.

“In the future, we also want to utilize the non-protein parts of the seaweed, which could be used in food, materials, or medical applications. The goal is for no molecule to go to waste, achieving both sustainability and commercial opportunities,” says Ingrid Undeland.

Conclusion

The extraction method developed in this study demonstrates the potential of seaweed as a sustainable protein source. Using Triton X-114 and acidification enabled the recovery of soluble and lipophilic proteins from U. fenestrata, resulting in a significant increase in protein extraction. This proof-of-concept study underscores the importance of exploring alternative protein sources, such as seaweed, to alleviate the pressure on land-based protein supply chains.

Additionally, the results of this research are complemented by the use of artificial intelligence for quality control during processing or pigment extraction.

Contact

Ingrid Undeland

Professor, Division of Food and Nutrition Science, Department of Life Sciences, Chalmers University of Technology,

Teléfono: +46 737 08 08 64

Email: undeland@chalmers.se

João Trigo, PhD,

Division of Food and Nutrition Science, Department of Life Sciences, Chalmers University of Technology

Teléfono: +46 739 78 74 16

Email: trigo@chalmers.se

Reference (open access)

Trigo, J. P., Steinhagen, S., Stedt, K., Krona, A., Verhagen, S., Pavia, H., Abdollahi, M., & Undeland, I. (2025). A new method for protein extraction from sea lettuce (Ulva fenestrata) via surfactants and alkaline aqueous solutions. Food Chemistry, 464, 141839. https://doi.org/10.1016/j.foodchem.2024.141839

Editor at the digital magazine AquaHoy. He holds a degree in Aquaculture Biology from the National University of Santa (UNS) and a Master’s degree in Science and Innovation Management from the Polytechnic University of Valencia, with postgraduate diplomas in Business Innovation and Innovation Management. He possesses extensive experience in the aquaculture and fisheries sector, having led the Fisheries Innovation Unit of the National Program for Innovation in Fisheries and Aquaculture (PNIPA). He has served as a senior consultant in technology watch, an innovation project formulator and advisor, and a lecturer at UNS. He is a member of the Peruvian College of Biologists and was recognized by the World Aquaculture Society (WAS) in 2016 for his contribution to aquaculture.