Microalgae are microscopic powerhouses with immense potential for biofuels, nutraceuticals, and even CO2 capture. However, scaling up their production from laboratory flasks to industrial production facilities presents a significant challenge. Current methods rely heavily on trial-and-error experimentation, which can be time-consuming and costly.

This is where a new and innovative approach comes into play! Researchers from Université de Nantes (France), Qatar University, Wageningen University (Netherlands), and Université Clermont Auvergne (France) have developed a simplified method that uses readily available engineering equations, eliminating the need for complex computer models that require specialized skills.

Challenges in Scaling Up Microalgae Production

Scaling up production from laboratory flasks to large-scale facilities remains a major obstacle in microalgae production. This challenge arises from two main issues:

- Technical complexities: Cultivating microalgae and maintaining robust cultures on a large scale presents unique technical challenges.

- Limited engineering tools: There are no simple tools to easily design production facilities for specific microalgae strains, especially for the less studied ones. This creates a significant bottleneck for commercialization.

Mathematical models have been touted as the key to unlocking efficient microalgae production. These models, particularly those aimed at predicting behavior in large-scale systems, have shown promise in aspects such as biomass productivity and the influence of factors like light exposure and harvesting strategies.

However, translating these models from laboratory settings to real-world solar-powered facilities remains a challenge. Unlike traditional bioprocesses, where yield is predictable based on volume, microalgae production heavily depends on sunlight, which varies significantly throughout the year and location.

The Role of Light and a New Approach

Light plays a crucial role in the growth of microalgae. The crux of the problem lies in the complex interaction between light exposure, how light penetrates the culture volume, and how this affects photosynthetic growth.

Most existing models attempt to predict this relationship with high accuracy, a crucial step in determining the productivity of a specific culture system based on factors like the species of microalgae grown, light received, system design, and operating parameters.

The Key is in Intelligent Simplification

The researchers have developed engineering equations derived from decades of photobioreactor (PBR) modeling for life support systems. These equations can determine the maximum productivity of a culture system under specific conditions (strain, light source, etc.). While they do not account for possible growth limitations, they provide crucial information for engineers. Knowing the maximum achievable yield helps determine the facility size and identify potential limitations by comparing it with actual results.

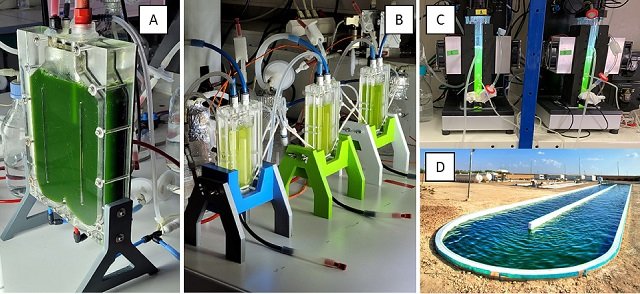

The validity of these equations has been established through various studies, covering cyanobacteria, microalgae, different PBR geometries (both tubular and flat-panel), and lighting conditions, both artificial and solar.

Stay Always Informed

Join our communities to instantly receive the most important news, reports, and analysis from the aquaculture industry.

However, a major drawback of these equations is the need for several parameters that require specialized equipment and methods for identification. These parameters, known as radiative properties, are often complex and require significant theoretical or experimental work to determine.

The article presents an innovative approach that simplifies the process of scaling up microalgae production. It uses adapted engineering equations that eliminate the need for complex measurements, making the process more accessible.

By intelligently adapting existing equations, the researchers eliminate complexities and focus on a few key factors determined through simple small-scale experiments specific to the microalgae strain being cultivated.

The new method aims to predict key data quickly and efficiently, eliminating the need for extensive initial studies and costly equipment. Here’s how it works:

- Simplified equations: Complex equations are intelligently adapted to eliminate parameters that are difficult to obtain.

- Specific experiments: A few conventional laboratory-scale experiments determine the remaining key parameters specific to the microalgae strain and light conditions.

Putting the Method to the Test

To demonstrate its effectiveness, the researchers applied this method to two different microalgae strains:

- Haematococcus pluvialis (in its green phase under continuous light)

- A strain of Picochlorum maculatum isolated from the harsh desert of Qatar (grown under continuous and day/night light cycles)

The results were impressive! The predicted yield, based on the simplified method, deviated by less than 10% from the actual data obtained through experimentation.

Benefits for Microalgae Cultivators

This revolutionary approach offers several advantages:

- Reduced experimentation time: By eliminating the need for lengthy trial-and-error processes, this method can significantly accelerate the scaling-up process, saving months of valuable research time.

- Simplified application: The method relies on readily available engineering equations and avoids complex computer modeling, making it accessible to a wider range of researchers and professionals.

- Faster development: With this new tool, researchers can optimize microalgae cultures for specific applications more efficiently.

Conclusion

This simplified approach has the potential to significantly streamline the process of scaling up microalgae production, paving the way for a more efficient and profitable future for this promising technology.

The study was funded by the DISCUS project of the NExT Initiative (Nantes Excellence Trajectory) International Research Partnership and by the International Research Center “Innovation Transportation and Production Systems” of the I-SITE CAP 20-25.

Contact

J. Pruvost

GEPEA, Université de Nantes, ONIRIS, CNRS, UMR6144, bd de l’Université, CRTT – BP 406, 44602 Saint-Nazaire Cedex, France

Email: Jeremy.pruvost@Univ-Nantes.fr

Reference (open access)

Pruvost, J., Rasheed, R., Samhat, K., Kazbar, A., Al Jabri, H., Dauchet, J., & Cornet, J. (2024). A simple new approach predicting how microalgae culture systems will perform under sunlight and artificial light conditions. Algal Research, 80, 103517. https://doi.org/10.1016/j.algal.2024.103517

Editor at the digital magazine AquaHoy. He holds a degree in Aquaculture Biology from the National University of Santa (UNS) and a Master’s degree in Science and Innovation Management from the Polytechnic University of Valencia, with postgraduate diplomas in Business Innovation and Innovation Management. He possesses extensive experience in the aquaculture and fisheries sector, having led the Fisheries Innovation Unit of the National Program for Innovation in Fisheries and Aquaculture (PNIPA). He has served as a senior consultant in technology watch, an innovation project formulator and advisor, and a lecturer at UNS. He is a member of the Peruvian College of Biologists and was recognized by the World Aquaculture Society (WAS) in 2016 for his contribution to aquaculture.