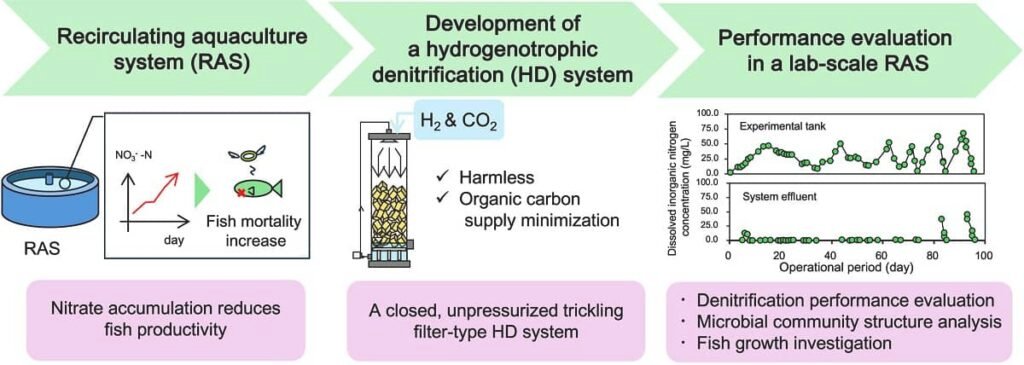

The accumulation of nitrate (NO₃⁻-N) in recirculating aquaculture systems (RAS) is a constant challenge that can compromise fish health and production efficiency. Although various technologies exist to address this issue, many have drawbacks, such as deteriorating water quality or producing toxic byproducts.

In this context, a team of scientists from the University of Yamanashi, Mahidol University, and Ramkhamhaeng University has developed and evaluated an innovative hydrogenotrophic denitrification (HD) system. This technology utilizes hydrogen gas (H₂) as a “clean” electron donor to convert nitrate into harmless nitrogen gas (N₂). The study, conducted at a laboratory scale in a RAS with rainbow trout (Oncorhynchus mykiss), demonstrates that this method is not only highly efficient but also completely safe for the fish.

Key findings

- A closed, non-pressurized, trickling filter-type hydrogenotrophic denitrification (HD) system was developed for recirculating aquaculture systems (RAS).

- The system achieved a maximum nitrogen removal rate of 504.0 g N/m³/d, demonstrating high efficiency in converting nitrate to nitrogen gas.

- The application of the HD system in a culture tank with rainbow trout (Oncorhynchus mykiss) for 100 days did not negatively affect fish growth, and no mortality was recorded.

- Bacteria from the genera Thauera and Dechloromonas were the dominant communities in the biofilter, being primarily responsible for the denitrification process.

- The technology uses hydrogen gas (H₂) as an electron donor, which minimizes sludge generation and toxicity compared to other denitrification methods.

The nitrate challenge in RAS

In any recirculating system, fish waste and uneaten feed release ammonium (NH₄⁺-N), which is converted to nitrate (NO₃⁻-N) by nitrifying bacteria in the biofilters. While nitrate is less toxic than ammonium or nitrite, its progressive accumulation can cause health problems in fish, such as methemoglobinemia, and reduce survival rates, thereby affecting the profitability of the operation.

Traditional methods for removing nitrate, such as heterotrophic denitrification, require the addition of an organic carbon source (e.g., methanol, glucose), which can degrade water quality and increase sludge production. Hydrogenotrophic denitrification emerges as a promising alternative because, by using hydrogen—a harmless compound that dissipates naturally—these drawbacks are avoided.

Design and optimization of a hydrogenotrophic denitrification system

The researchers designed a closed, non-pressurized, trickling filter-type reactor to maximize the contact among the water, denitrifying bacteria, and hydrogen gas.

To optimize the system, they first evaluated three types of bacterial carriers (polypropylene rings, ceramic rings, and polyolefin sponges), concluding that the polyolefin sponge was the most effective for immobilizing bacterial sludge due to its large surface area. Subsequently, they compared two modes of operation: a moving bed system and a trickling filter system. The trickling filter demonstrated a higher nitrogen removal rate, likely due to more efficient mass transfer of hydrogen into the water.

The final 5.2-liter system was filled with the polyolefin sponges inoculated with bacteria and was continuously supplied with hydrogen gas (H₂) and periodically with carbon dioxide (CO₂) to maintain a stable pH.

High efficiency without compromising fish health

The HD system was integrated into a 60-liter RAS where adult rainbow trout were cultured for approximately 100 days. The results were compelling:

- Superior Nitrogen Removal Performance: The system reached a maximum nitrogen removal rate (NRR) of 504.0 g N/m³/d with a hydraulic retention time (HRT) of just 1 hour, achieving a removal efficiency of 94.2%. This figure is higher than that of other HD systems previously reported for aquaculture and is comparable to high-performance reactors for groundwater treatment.

- Efficient Hydrogen Consumption: At its peak efficiency, the system required 5.5 liters of H₂ and 2.1 liters of CO₂ to remove one gram of nitrogen. This indicates that approximately 87.3% of the supplied hydrogen was effectively used in the denitrification process.

- Fish Growth and Well-being: The most significant finding for producers is that the effluent from the HD system, when recirculated directly to the fish tank, had no negative impact on their growth. The total weight of the fish in the experimental tank increased similarly to that of the control tank (which used water exchanges), and no mortality was observed throughout the experiment.

The key bacteria in the process

Microbial analysis of the reactor sludge revealed that two bacterial genera, Thauera and Dechloromonas, were dominant, jointly representing over 42% of the bacterial community by the end of the experiment. The increase in the abundance of these bacteria, along with the rise in functional genes related to denitrification (narG, nirk, nirS, nosZ), confirms their central role in nitrate removal within the system.

Stay Always Informed

Join our communities to instantly receive the most important news, reports, and analysis from the aquaculture industry.

Implications and future of hydrogenotrophic denitrification

This study demonstrates that hydrogenotrophic denitrification is a viable and highly promising technology for nitrogen management in freshwater RAS. Its main advantages include:

- Biocompatibility: It does not use organic compounds that could affect water quality or produce toxic byproducts.

- Simple Operation: It only requires a controlled supply of H₂ and CO₂, gases that can be generated on-site, reducing dependence on external inputs.

- Lower Sludge Production: As it relies on the growth of autotrophic bacteria, sludge generation is minimal compared to heterotrophic systems.

The authors note that although no adverse effects were observed, the system did increase the concentration of viable bacteria in the tank water. Therefore, they recommend that in a commercial-scale implementation, the denitrification unit be installed before the disinfection unit (e.g., UV) to minimize any risk.

The success of this technology opens the door for future optimizations for large-scale applications, offering the aquaculture industry a powerful tool to enhance the sustainability and efficiency of recirculating culture systems.

Contact

Tatsuru Kamei

Interdisciplinary Centre for River Basin Environment, University of Yamanashi

4-4-37 Takeda, Kofu Yamanashi, 400-8510, Japan

Email: tkamei@yamanashi.ac.jp

Reference (open access)

Kamei, T., Atsuta, H., Rujakom, S., & Eamrat, R. (2025). Development of a hydrogenotrophic denitrification system for recirculating aquaculture. Journal of Environmental Management, 394, 127285. https://doi.org/10.1016/j.jenvman.2025.127285

Editor at the digital magazine AquaHoy. He holds a degree in Aquaculture Biology from the National University of Santa (UNS) and a Master’s degree in Science and Innovation Management from the Polytechnic University of Valencia, with postgraduate diplomas in Business Innovation and Innovation Management. He possesses extensive experience in the aquaculture and fisheries sector, having led the Fisheries Innovation Unit of the National Program for Innovation in Fisheries and Aquaculture (PNIPA). He has served as a senior consultant in technology watch, an innovation project formulator and advisor, and a lecturer at UNS. He is a member of the Peruvian College of Biologists and was recognized by the World Aquaculture Society (WAS) in 2016 for his contribution to aquaculture.