The cold chain is the backbone that ensures the quality and safety of aquaculture products from farm to consumer. However, its high energy consumption and environmental impact pose a growing challenge for a sector committed to sustainability. While effective, traditional refrigeration methods often entail a significant ecological cost.

Addressing the lack of quantitative tools to measure and improve environmental performance, new research in the journal Environmental Development by researchers from the National Taipei University of Technology and Tunghai University develops a comprehensive, formula-based framework to assess cold chain sustainability, with direct application to the aquaculture industry. This model not only identifies critical areas for improvement but also offers a roadmap for companies to optimize their resources, benchmark against their peers, and advance toward greener, more efficient operations.

Key findings

- The “Planning” dimension, which includes energy-saving policies and infrastructure investment, is the most influential factor in achieving a sustainable cold chain, according to experts.

- The study establishes a framework with 12 quantifiable indicators in the areas of Planning, Operation, and Service, enabling companies to measure, compare, and improve their performance.

- For the aquaculture sector, the two most important improvement measures are creating “Joint Carbon-Reduction Supply Chains” and ensuring “Aquatic Product Quality and Safety Monitoring.”

- The framework is not merely theoretical; it was applied to eight aquaculture firms, demonstrating how to identify performance gaps and guide the implementation of customized solutions like real-time tracking systems and collaborative warehouses.

How the evaluation model was constructed

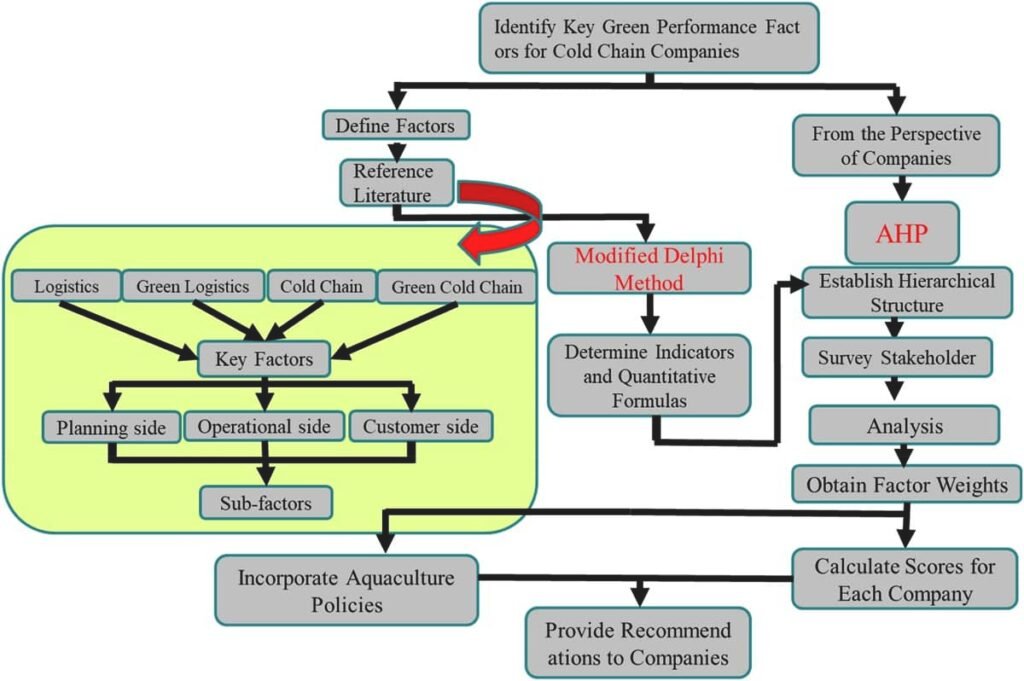

To develop a robust and relevant evaluation system, the researchers combined several methodologies. First, they conducted an extensive review of scientific literature on logistics, green logistics, and the cold chain to identify the most crucial performance indicators.

Subsequently, they used the Modified Delphi Method, a technique that gathers and consolidates the opinions of a panel of industry and academic experts to validate the selected indicators and develop quantitative formulas to measure them. Finally, they employed the Analytic Hierarchy Process (AHP) to assign a weight or level of importance to each indicator, reflecting the priorities of both industry experts and consumers.

The 12 key indicators for a sustainable cold chain

The study consolidated its analysis into an evaluation framework composed of three main dimensions and twelve key performance indicators. According to industry experts, the Planning dimension is by far the most significant (weight of 0.419), followed by Operation (0.345) and Service (0.236).

This highlights that strategic decisions made by senior management, such as energy-saving policies and infrastructure investment, are fundamental to a successful, sustainable transformation.

The identified indicators are:

Planning Dimension:

- Energy-Saving Facilities: Proportion of efficient warehouses and vehicles.

- Clean Energy Sources: Use of green electricity, eco-friendly refrigerants, and electric vehicles.

- Route Planning: Optimization to reduce idling and time in traffic jams.

- Green Packaging: Use of recyclable and reusable materials.

- Employee Education: Training in energy conservation and feedback collection.

Operation Dimension:

Stay Always Informed

Join our communities to instantly receive the most important news, reports, and analysis from the aquaculture industry.

- Joint Transportation: Use of multi-temperature vehicles with adequate load capacity.

- Infrastructure: Regular maintenance of trucks and compressors.

- Information Operations: Adoption of vehicle and warehouse management systems.

- Monitoring and Traceability: Utilization of monitoring technology and operation records.

Service Dimension:

- Service Quality: Rate of undamaged products and the existence of reverse logistics.

- Customer Satisfaction: Rate of customer feedback adoption.

- Partner Relations: Collaboration with other manufacturers to improve efficiency.

Within these twelve, the three indicators with the greatest overall weight according to experts were Energy-Saving Facilities (0.143), Service Quality (0.128), and Monitoring and Traceability (0.103).

Practical application: What are the priorities for aquaculture?

The study went beyond theory, applying this framework to Taiwan’s aquaculture sector to identify the most effective improvement strategies. Four main improvement measures were evaluated:

- Waste reduction and sorting for recycling.

- Joint regional processing and storage.

- Monitoring of aquatic product quality and safety.

- Joint supply chain for carbon reduction.

The analysis revealed a clear order of priority. The most important strategy, with a weighted score of 0.328, was the “Joint Supply Chain for Carbon Reduction.” This measure focuses on integrating information, resources, and services across the entire chain to improve service quality and strengthen partnerships. The second priority, with a score of 0.257, was “Monitoring of Aquatic Product Quality and Safety,” which relies on real-time tracking and accurate data records to ensure product integrity.

Lessons from benchmarking: Learning from peers

To validate the model’s utility as a diagnostic tool, the performance of eight diverse aquaculture companies (from shrimp farms to wholesalers and processors) was evaluated. The analysis helped visualize the “improvement gaps” for each company compared to the top performer, identifying priority areas for action.

The results showed common challenges in the sector, such as the need to improve route planning (an area for improvement for 7 of the 8 companies), the urgency of upgrading energy-saving infrastructure (identified by 5 companies), and the lack of employee training programs in green logistics, especially in SMEs. This evaluation allows companies, even smaller ones with limited resources, to focus their efforts on the highest-impact areas, such as adopting clean energy solutions or implementing GPS technology to optimize routes.

Conclusion

This study offers a valuable contribution to the aquaculture sector by providing a structured, data-driven tool for transitioning toward a more sustainable cold chain. The key message is that the green transformation starts at the top, with strategic planning and decisive investment in efficient infrastructure. At the same time, it is crucial not to neglect service quality and traceability, as sustainability must go hand-in-hand with profitability and consumer trust.

This model equips managers and decision-makers with a clear guide to allocate resources effectively, align their operations with sustainability goals, and ultimately, build a more resilient and environmentally friendly aquaculture supply chain.

Contact

Hsin-Wei Hsu

Department of Industrial Engineering and Management, National Taipei University of Technology, Taipei, Taiwan

Email: hwhsu@ntut.edu.tw

Reference (open access)

Hsu, H., & Lo, Y. (2026). Innovative sustainable cold chain evaluation model: Application to the aquaculture sector. Environmental Development, 57, 101319. https://doi.org/10.1016/j.envdev.2025.101319

Editor at the digital magazine AquaHoy. He holds a degree in Aquaculture Biology from the National University of Santa (UNS) and a Master’s degree in Science and Innovation Management from the Polytechnic University of Valencia, with postgraduate diplomas in Business Innovation and Innovation Management. He possesses extensive experience in the aquaculture and fisheries sector, having led the Fisheries Innovation Unit of the National Program for Innovation in Fisheries and Aquaculture (PNIPA). He has served as a senior consultant in technology watch, an innovation project formulator and advisor, and a lecturer at UNS. He is a member of the Peruvian College of Biologists and was recognized by the World Aquaculture Society (WAS) in 2016 for his contribution to aquaculture.