A recent study published in the journal Fishes by researchers from the Universidad Cooperativa de Colombia, Universidade Estadual Paulista (Unesp), Universidade Nilton Lins, and the Instituto de Pesca examined the economic aspects of red tilapia production using biofloc technology under different sources of electrical energy, including conventional energy, combined conventional and photovoltaic energy, full photovoltaic energy, and a simulation of surplus photovoltaic energy generation for nighttime use.

The Challenge of Energy Costs in Aquaculture

Electricity is the primary source of energy used in aquaculture, representing between 10% and 25% of production costs in systems with intensive electricity loads. Energy is used for various purposes, including water pumping, aeration, and heating.

For example, oxygenation equipment in recirculating aquaculture systems (RAS) consumes 20% of the total energy used, adding 5% to the final product cost per kilogram.

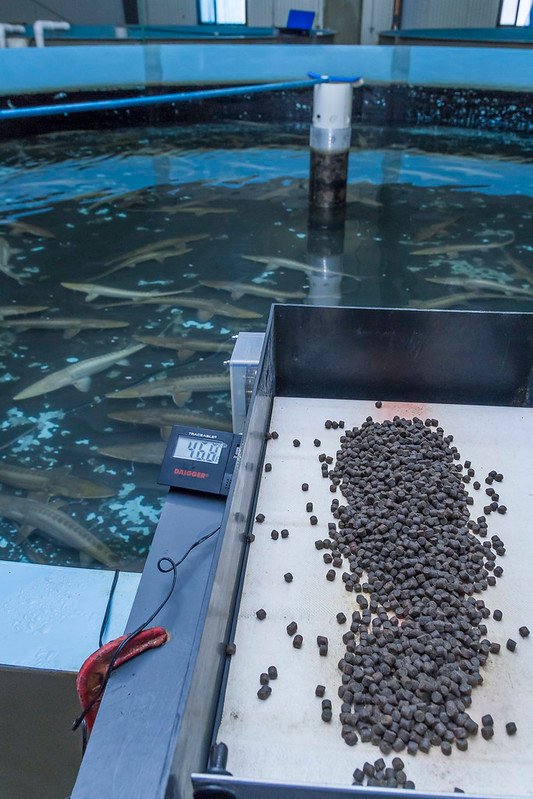

In biofloc systems (BFT), aeration is particularly energy-intensive and contributes to a substantial portion of overall energy costs. The cost of electrical energy in BFT systems can account for up to 15% of production costs. In this sense, reliance on electricity can expose aquaculture producers to fluctuating energy prices, making production costs difficult to predict and manage.

Alternative Energy Sources

Several alternative energy sources have been proposed for use in aquaculture, including geothermal energy, biogas, wind energy, tidal energy, and photovoltaic energy. Photovoltaic energy is a promising alternative, with studies showing its potential in tilapia and shrimp hatcheries, recirculating systems, and marine fish production.

Photovoltaic (PV) technology, which converts sunlight into electricity, offers a renewable and cost-effective alternative to traditional energy sources for aquaculture. By harnessing solar energy, aquaculture producers can reduce their dependence on the power grid, mitigate environmental impact, and improve the long-term sustainability of their operations.

The Study

To evaluate the economic feasibility of BFT systems powered by photovoltaic energy for red tilapia production, researchers conducted a comparative analysis of four energy scenarios:

- Conventional Electrical Energy (CE): Relies solely on the electrical grid.

- Combined Conventional and Photovoltaic Energy (CPVE): Uses photovoltaic energy during daylight hours and grid electricity at night.

- Full Photovoltaic Energy (PVE): Operates entirely on photovoltaic energy, with battery storage.

- Surplus Photovoltaic Energy Generation (PVES): Generates excess photovoltaic energy during the day to offset nighttime consumption, avoiding the need for batteries.

Key Study Results

The results showed that the full photovoltaic energy treatment (PVE) had the highest initial investment due to the cost of solar panels and batteries but also had the lowest operating energy costs. However, overall costs for photovoltaic energy treatments increased due to depreciation and maintenance.

Feed was the largest production cost in most treatments, followed by labor, while depreciation was a significant cost factor for the PVE treatment. The total operating cost (TOC) of photovoltaic systems (PVE and PVES) was lower compared to conventional energy (CE), with PVES showing the greatest cost savings.

Stay Always Informed

Join our communities to instantly receive the most important news, reports, and analysis from the aquaculture industry.

The study highlights the potential of solar energy systems to improve the economic feasibility of aquaculture production, making them a favorable option for long-term sustainable production. However, the research also underscores the need to align the adoption of sustainable energy with market strategies in aquaculture. The findings suggest that economic feasibility depends on improving sales prices to offset higher production costs.

Key Findings of the Study

- Energy Costs and Economic Feasibility: The study revealed that photovoltaic energy systems (PVE and PVES) significantly reduced total operating costs compared to conventional energy (CE). The PVES treatment, in particular, demonstrated the greatest cost savings.

- Production Costs: Feed emerged as the most substantial production cost, followed by labor in most treatments. Depreciation was a significant cost factor for the PVE treatment.

- Impact of Solar Energy Integration: While solar energy integration offers long-term sustainability benefits, it requires higher initial investments. Strategies to increase sales prices or reduce other production costs are essential to ensure economic feasibility.

Implications for the Aquaculture Industry

The study’s findings have significant implications for the tilapia farming industry using biofloc systems, emphasizing the need to adopt sustainable energy practices to reduce operating costs and improve economic viability.

Furthermore, integrating solar energy systems into fish farming operations can help reduce the industry’s carbon footprint and contribute to a more sustainable future. However, the industry must also focus on improving sales prices to offset higher production costs and ensure the long-term viability of adopting sustainable energy.

Conclusion

The study demonstrates the potential of solar energy systems to improve the economic feasibility of aquaculture production, making them a favorable option for long-term sustainable production. However, the industry must align the adoption of sustainable energy with market strategies to ensure economic viability.

By adopting sustainable energy practices and improving sales prices, the aquaculture industry can contribute to a more sustainable future while maintaining economic viability.

The study was funded by the General System of Royalties, Colombia.

Reference (open access)

Cala-Delgado, D. L., Ismael da Costa, J., & Garcia, F. (2024). Economic Analysis of Red Tilapia (Oreochromis sp.) Production Under Different Solar Energy Alternatives in a Commercial Biofloc System in Colombia. Fishes, 9(12), 505. https://doi.org/10.3390/fishes9120505

Editor at the digital magazine AquaHoy. He holds a degree in Aquaculture Biology from the National University of Santa (UNS) and a Master’s degree in Science and Innovation Management from the Polytechnic University of Valencia, with postgraduate diplomas in Business Innovation and Innovation Management. He possesses extensive experience in the aquaculture and fisheries sector, having led the Fisheries Innovation Unit of the National Program for Innovation in Fisheries and Aquaculture (PNIPA). He has served as a senior consultant in technology watch, an innovation project formulator and advisor, and a lecturer at UNS. He is a member of the Peruvian College of Biologists and was recognized by the World Aquaculture Society (WAS) in 2016 for his contribution to aquaculture.