The sustainability of aquaculture and the conservation of marine biodiversity depend largely on our ability to master reproductive cycles in captivity. However, a historic technical barrier persists: the efficient harvesting of pelagic eggs. Currently, only 10% of fish species traded for aquariums come from captive breeding; the remainder still relies on extraction from the wild.

To reverse this statistic and enhance food production, a new patent developed by the ECOAQUA University Institute at the University of Las Palmas de Gran Canaria (ULPGC) presents a disruptive solution. The invention (ES 3032361), authored by Dr. Andrea Martino alongside professors Daniel Montero (Aquaculture Research Group – GIA) and Francisco Otero-Ferrer (Biodiversity and Conservation Group – BIOCON), promises to transform hatchery protocols through advanced hydrodynamics.

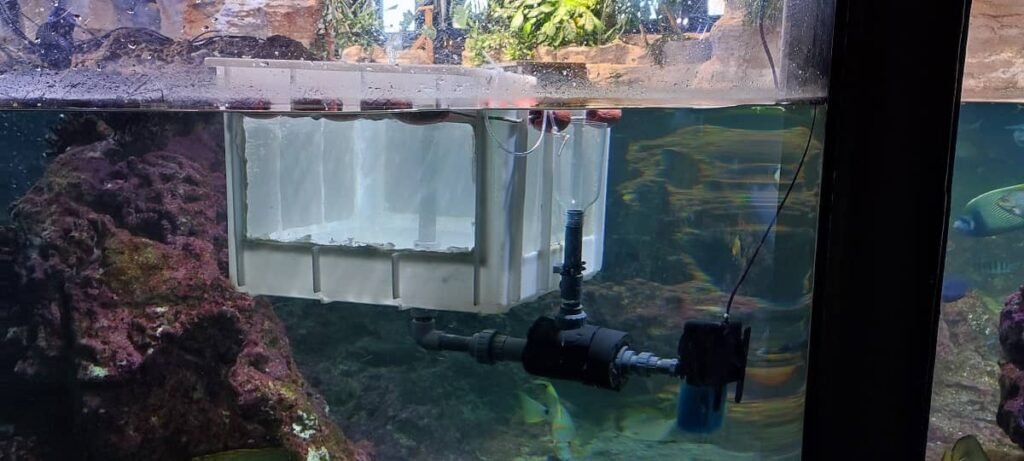

Validated in large-volume facilities such as the Aquarium of Genoa, this device not only exponentially increases the quantity of harvested eggs but also ensures their physical integrity, prioritizing both animal welfare and operational efficiency.

- 1 Key Innovations

- 2 The Challenge: Harvesting Without Harm

- 3 The Solution: Stable Suction via the Venturi Effect

- 4 Validation at the Aquarium of Genoa: Compelling Evidence

- 5 Impact on Animal Welfare and Conservation

- 6 Versatility for the Aquaculture Industry

- 7 Technology Transfer: From Lab to Market

- 8 Entradas relacionadas:

Key Innovations

- Multiplied Efficiency: The system collects five times more eggs than traditional “Airlift” pumps.

- Venturi Principle: It utilizes changes in pipe cross-sections to generate stable suction without air or turbulence.

- Superior Viability: Egg survival rates reach 84.5%, compared to 48.3% with conventional methods.

- Versatility and Modularity: Adaptable to small laboratories or large commercial tanks without structural alterations.

The Challenge: Harvesting Without Harm

“One of the main challenges in the controlled production of marine species is collecting the eggs released into the water without damaging them, causing stress, or altering tank dynamics,” explains Dr. Andrea Martino, the lead researcher on the invention.

Until now, the industry relied on compressed air pumps, or “Airlifts.” While popular, these devices generate turbulent flow by mixing air and water. This turbulence creates foam and bubbles that strike fragile embryos, drastically reducing their viability. Furthermore, many eggs become stranded and dry out on the rims of older collectors, resulting in lost harvests.

The Solution: Stable Suction via the Venturi Effect

The ULPGC innovation breaks the compressed air paradigm. The device operates using the physical principle of the Venturi effect as a source of stable, continuous suction.

How the Technology Works

The system integrates directly into tanks and features a specific hydrodynamic design:

- Airless Vacuum Generation: Water is propelled through a tube featuring a change in cross-section (conical constriction). As it passes this point, fluid velocity increases and pressure drops, creating powerful yet gentle suction at the collector.

- Laminar Flow: “By operating without air in the conduit, we achieve much more stable and precise suction,” details Martino. This prevents the formation of foam and damaging turbulence.

- Autonomous Filtering: Eggs are guided into a floating concentration chamber where they are retained by 300-micron mesh screens, eliminating the need for constant manual intervention.

This technology achieved a suction force of 1800 L/h during testing, quadrupling the capacity of traditional Airlift systems, which processed only 450 L/h.

Validation at the Aquarium of Genoa: Compelling Evidence

This technology is not merely theoretical; it has been validated under real operating conditions at the Acquario di Genova (Italy). During a 10-day study in a 190,000-liter tank housing multiple species, the new system was benchmarked against the industrial standard.

Stay Always Informed

Join our communities to instantly receive the most important news, reports, and analysis from the aquaculture industry.

The results, focusing on the Orbicular batfish (Platax orbicularis), were conclusive:

- Abundance: While the traditional system collected an average of 226.9 eggs, the ULPGC patent reached 1,149.1 eggs, a fivefold increase in harvest size.

- Viability: The quality of collected eggs rose from a poor 48.3% with the old system to an excellent 84.5% with the new technology.

Dr. Martino highlights that “having high-quality, concentrated, and easy-to-handle eggs opens up possibilities for both industry and science,” enabling the design of high-precision reproductive experiments.

Impact on Animal Welfare and Conservation

Beyond production figures, the ECOAQUA team emphasizes the invention’s ethical and conservationist value. “We reduce direct handling, lower the risk of injury, and avoid subjecting broodstock to intrusive processes,” states Martino.

This approach is vital for public aquariums and conservation centers. By facilitating reliable reproduction in captivity, pressure on wild populations is alleviated. “In aquariums, reproducing species reliably is fundamental to avoiding extraction from the natural environment,” notes the researcher, recalling that the vast majority of ornamental fish are still captured in their habitats.

Versatility for the Aquaculture Industry

The design is intended to be “plug-and-play.” Its modular nature facilitates incorporation into existing systems without expensive structural modifications.

- Adaptability: It can operate by leveraging the existing flow of filtration systems (RAS or LSS) or via a dedicated pump.

- Scalability: Martino assures that the system can be adjusted “from small laboratory tanks to large commercial installations.”

- Durability: Manufactured from materials such as polyvinyl chloride (PVC), it withstands long-term seawater corrosion.

Technology Transfer: From Lab to Market

With the patent’s publication, ULPGC seeks to transfer this knowledge to the productive sector. The goal is for the tool to reach production farms and research centers to improve global aquaculture sustainability.

“It is a simple, robust technology based on years of operational experience,” concludes Dr. Andrea Martino, adding that collaborations with interested companies are already being evaluated. This innovation represents a clear example of how university research can solve concrete industrial problems, simultaneously improving economic profitability and ecological responsibility.

Reference:

Montero, D., Martino, A., & Otero, F. (2025). Sistema recolector de huevos de animales acuáticos (Patente No. ES 3 032 361 B2). Oficina Española de Patentes y Marcas.

Editor at the digital magazine AquaHoy. He holds a degree in Aquaculture Biology from the National University of Santa (UNS) and a Master’s degree in Science and Innovation Management from the Polytechnic University of Valencia, with postgraduate diplomas in Business Innovation and Innovation Management. He possesses extensive experience in the aquaculture and fisheries sector, having led the Fisheries Innovation Unit of the National Program for Innovation in Fisheries and Aquaculture (PNIPA). He has served as a senior consultant in technology watch, an innovation project formulator and advisor, and a lecturer at UNS. He is a member of the Peruvian College of Biologists and was recognized by the World Aquaculture Society (WAS) in 2016 for his contribution to aquaculture.