The shrimp farming industry has the potential to significantly contribute to the economy and food security in the countries where it is practiced. However, the success of shrimp farming depends on effective management practices and the ability to address various challenges. Traditional methods often struggle to maintain optimal water conditions, prevent disease outbreaks, and ensure consistent feeding schedules.

The advent of Industry 4.0 has revolutionized various sectors, and aquaculture is no exception. By leveraging Internet of Things (IoT) technology, aquaculturists can now optimize their operations, improve efficiency, and enhance the quality of their products.

To address these issues, an intelligent aquaculture system that integrates Internet of Things (IoT) technology offers a promising solution. A study published by researchers at Bina Nusantara University (Indonesia) explores the potential of an intelligent aquaculture system for shrimp farming based on the Quality Function Deployment (QFD) method to tackle these problems.

The Role of Smart Aquaculture

IoT devices, equipped with sensors and connectivity, can collect and analyze data from aquaculture environments in real-time. This data-driven approach allows aquaculturists to make informed decisions about water quality management, feeding, and overall pond health. The key benefits of IoT-based aquaculture include:

- Enhanced water quality monitoring: Real-time monitoring of parameters such as temperature, pH, dissolved oxygen, and salinity helps maintain optimal conditions for shrimp growth.

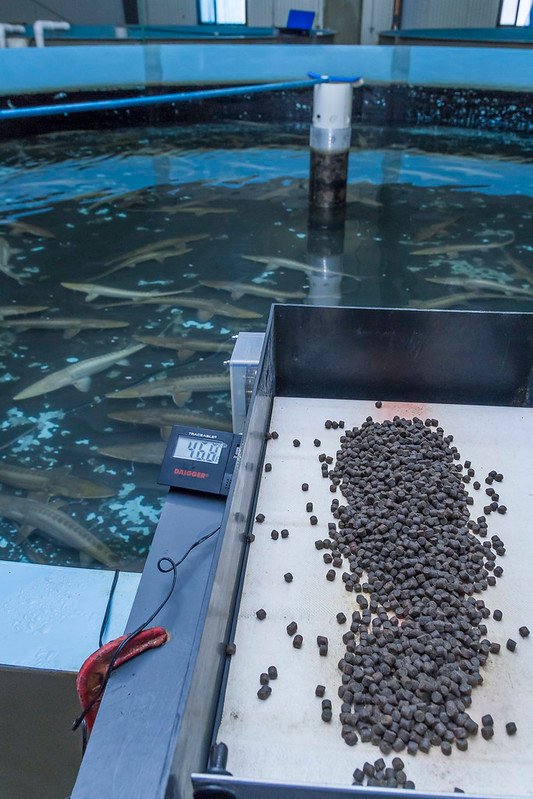

- Automated feeding systems: Precisely controlled feeding schedules based on shrimp size and nutritional needs reduce waste and ensure efficient feed utilization.

- Disease prevention and detection: Early detection of abnormalities in water quality or shrimp behavior can help prevent disease outbreaks.

- Increased efficiency: Automating routine tasks reduces labor costs and boosts productivity.

The QFD Approach

To ensure that the smart aquaculture system meets the specific needs of shrimp farmers, the researchers employed the Quality Function Deployment (QFD) method.

QFD is a structured approach that helps translate customer requirements into product or service features. By involving farmers in the design process, the researchers were able to tailor the system to their specific needs and preferences.

The researchers’ approach involved:

- Identifying stakeholders and assessing needs: Questionnaires were distributed to identify key stakeholders, including aquaculturists, government agencies, and consumers. Their preferences and requirements were gathered to understand the desired features of the smart aquaculture system.

- Designing and optimizing the system: Using the QFD matrix, the collected data was analyzed to identify critical factors influencing system performance. The matrix helped prioritize features and allocate resources accordingly, ensuring the system effectively meets stakeholders’ needs.

Key Findings and Benefits

According to the results of the study published in the Binus Journal Publishing, the QFD-based design resulted in a smart aquaculture system for shrimp farming that addresses the following critical aspects:

- Water quality management: Real-time monitoring of parameters such as pH, temperature, dissolved oxygen, and salinity ensures optimal conditions for shrimp growth.

- Disease prevention: Early detection of pathogens through advanced sensors and automated water treatment systems helps prevent outbreaks.

- Feeding optimization: Automated feeding mechanisms provide the right amount of feed at the right time, promoting healthy growth and reducing waste.

- Data-driven decision-making: The system provides valuable insights into farm performance, enabling aquaculturists to make informed decisions on feed management, water quality adjustments, and disease prevention.

- Improved efficiency: Automation reduces labor costs and enhances operational efficiency.

- Enhanced sustainability: By optimizing resource use and minimizing environmental impact, the smart aquaculture system contributes to sustainable practices.

Conclusion

The QFD-based smart aquaculture system offers a promising solution to the challenges faced by shrimp farmers. By integrating technology and stakeholder input, this approach can boost productivity, improve sustainability, and contribute to the overall growth of the aquaculture industry.

Stay Always Informed

Join our communities to instantly receive the most important news, reports, and analysis from the aquaculture industry.

Contact

Budi Setiawan

Industrial Engineering Department, BINUS Graduate Program – Master of Industrial Engineering, Bina Nusantara University

Jakarta, Indonesia 11480

Email: budi.setiawan004@binus.ac.id

Reference (open access)

B. Setiawan and N. Surantha, “Smart Aquaculture Design for Vannamei Shrimp Farming Based on Quality Function Development”, CommIT Journal 18(2), 229–250, 2024.

Editor at the digital magazine AquaHoy. He holds a degree in Aquaculture Biology from the National University of Santa (UNS) and a Master’s degree in Science and Innovation Management from the Polytechnic University of Valencia, with postgraduate diplomas in Business Innovation and Innovation Management. He possesses extensive experience in the aquaculture and fisheries sector, having led the Fisheries Innovation Unit of the National Program for Innovation in Fisheries and Aquaculture (PNIPA). He has served as a senior consultant in technology watch, an innovation project formulator and advisor, and a lecturer at UNS. He is a member of the Peruvian College of Biologists and was recognized by the World Aquaculture Society (WAS) in 2016 for his contribution to aquaculture.