The search for sustainable protein sources is a hot topic, and from the depths of the ocean has emerged a surprising contender: sea lettuce (Ulva sp.). This fast-growing algae has immense potential, and researchers are uncovering its secrets to maximize its nutritional value. Researchers are discovering Ulva’s potential due to its high protein content. But how can we maximize this benefit?

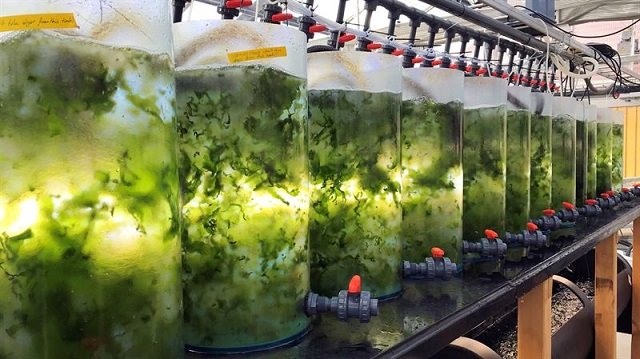

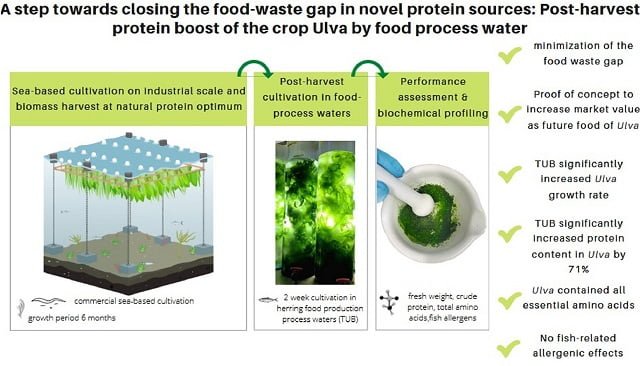

A new study published by scientists from the University of Gothenburg and Chalmers University of Technology explored post-harvest treatment of commercially produced algae biomass from large-scale marine Ulva fenestrata farming with wastewater streams emerging from industrial herring storage, the so-called herring production tank water (TUB).

They are seeking post-harvest techniques to increase protein levels in commercially produced Ulva. They focused on a fascinating approach: using wastewater from the food industry, such as leftover water from herring storage tanks.

Why algae? A sustainable protein source

Algae offers a unique opportunity for sustainable food production. Unlike land crops, they don’t compete for valuable space and thrive in offshore farms. This “ocean farming” has immense potential to increase protein production without harming the environment.

Algae boast an impressive nutritional profile. It’s packed with proteins, essential minerals, antioxidants, vitamins, and dietary fibers. It even contains long-chain PUFA n-3 (omega-3 fatty acids) and vitamin B12, often lacking in vegetarian diets. This makes algae a powerful player in the growing plant-based protein market, especially as current options sometimes struggle to meet both nutritional and flavor demands.

Challenges and breakthroughs: boosting protein content

While some species of seaweed have naturally high protein content, the average falls short compared to land plants like soy. However, researchers are discovering innovative methods to overcome this hurdle.

One such technique involves a “circular food production system.” This approach uses leftover water from herring processing (herring production tank water or TUB) as post-harvest treatment for Ulva.

Ulva: The rising star of seaweed protein

Among the many types of algae, Ulva (sea lettuce) is garnering significant interest. Ulva grows rapidly, adapts to changing environments, and is efficient at cleaning excess nutrients from water. However, its protein content can vary depending on growing conditions.

Turning food waste into protein

The study explored the effects of TUB on large-scale marine farms of Ulva fenestrata. The results were impressive! Algae treated with TUB showed significantly higher growth rates compared to those grown without it.

Stay Always Informed

Join our communities to instantly receive the most important news, reports, and analysis from the aquaculture industry.

According to the study authors: “Our work reveals that post-harvest treatment using herring production process water (TUB), which is typically treated as waste, can enhance the nutritional quality of northern hemisphere U. fenestrata cultivation. Specifically, the treatment elevates crude protein content and essential amino acids beyond natural levels.”

But what truly changed the game was the protein content. Ulva fenestrata cultivated with TUB showed a staggering 71% increase in crude protein content, reaching a remarkable 37.37% of dry weight.

Complete protein without allergies

This protein increase isn’t just about quantity but also quality. The study found no limiting amino acids in algae treated with TUB, meaning it provides a complete source of protein. Additionally, no fish-related allergenic activity was detected, making it a safe option for people with seafood allergies.

A sustainable circuit for the future

This research highlights the potential of Ulva cultivation as a sustainable protein source. In particular, it demonstrates a closed-loop system where food industry waste is transformed into a valuable resource. By using leftover water flows, we can grow protein-rich algae while minimizing environmental impact.

Conclusion

“Our study reveals that the naturally optimal protein content of U. fenestrata biomass can be increased through short-term post-harvest treatments with herring production process water,” concluded the researchers.

This study is just a glimpse into the exciting possibilities of Ulva and other seaweeds. As research progresses, we can expect even more innovative techniques to unleash their full potential as a sustainable and nutritious food source in the future.

The study was funded by the Swedish Government Research Council FORMAS.

Contact

Sophie Steinhagen

Department of Marine Sciences, Tjärnö Marine Laboratory, University of Gothenburg

Laboratorievägen 10, Strömstad SE-452 96, Sweden

Email: sophie.steinhagen@gu.se

Reference (open access)

Steinhagen, S., Stedt, K., Trigo, J. P., Undeland, I., & Pavia, H. (2024). A step towards closing the food-waste gap in novel protein sources: Post-harvest protein boost of the seaweed crop Ulva by herring production tub water. Future Foods, 9, 100347. https://doi.org/10.1016/j.fufo.2024.100347

Editor at the digital magazine AquaHoy. He holds a degree in Aquaculture Biology from the National University of Santa (UNS) and a Master’s degree in Science and Innovation Management from the Polytechnic University of Valencia, with postgraduate diplomas in Business Innovation and Innovation Management. He possesses extensive experience in the aquaculture and fisheries sector, having led the Fisheries Innovation Unit of the National Program for Innovation in Fisheries and Aquaculture (PNIPA). He has served as a senior consultant in technology watch, an innovation project formulator and advisor, and a lecturer at UNS. He is a member of the Peruvian College of Biologists and was recognized by the World Aquaculture Society (WAS) in 2016 for his contribution to aquaculture.