Norway.- Full temperature control leads to better sausages, control of water content means better french fries, and knowledge of the amount of fat in salmon improves customer differentiation.

In the SmartSensor project, researchers from Nofima and Sintef Digital are developing an instrument that can rapidly take measurements in food directly in the production line.

“This type of instrument will be of great value to food manufacturers because better control will make it easier to handle varying raw material quality, which will reduce waste. We have now completed the development of Prototype version 2, which is currently being tested in companies,” says Jens Petter Wold, senior researcher at Nofima and project manager.

Better control = increased profitability

For Nortura, the main point is better control of the core temperature in hot dog sausages. Sausages that are safe to eat must have a core temperature above 72°C, but if the temperature exceeds 78°C, they lose more water than necessary, become less juicy, and profitability decreases. Today, core temperatures are measured by sampling when necessary. The goal of the new prototype is continuous measurement and control. If the temperature is not at target, it can be immediately adjusted.

“Measuring the core temperature of each sausage as they pass through the oven has been both challenging and enjoyable. Water vapour, humidity, little space and the fact that we couldn’t see the sausages we were measuring made this quite a job. But we solved many of the problems through close cooperation between Nortura, Nofima and Sintef,” says Sintef researcher Marion O’Farrell.

There is great variation in the amounts of dry matter and water in different potatoes. For Findus, it is important to be able to measure the water content of potatoes and potato strips during the production process. Potatoes with too little dry matter can be removed and used for other products, and the frying process can be adjusted optimally in terms of the water content of the potato strips, resulting in deliciously French fries. This project has shown us that we can accurately measure the dry matter in each potato in the lab, and we have now got very promising results from process measurements as well.

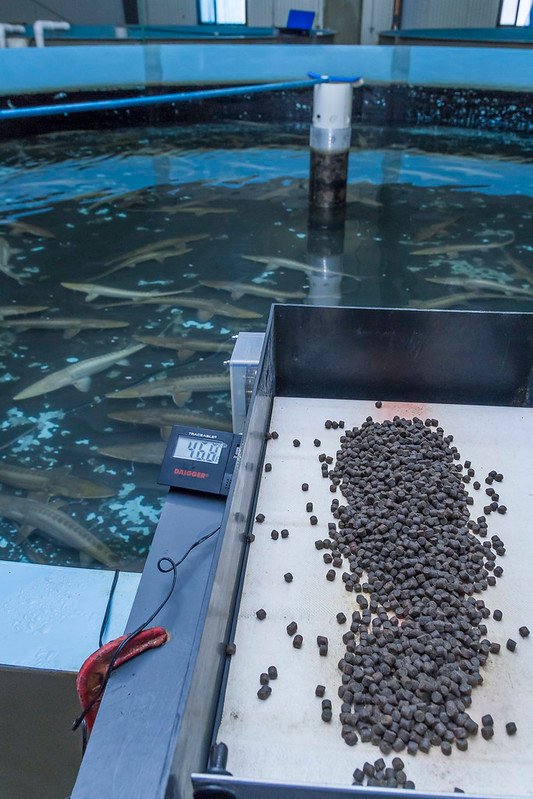

In addition, the salmon producer Cermaq is interested in finding out whether the technology can be used to measure the quality of whole salmon. This will enable better production management at the individual level and make production more customer-friendly.

Stay Always Informed

Join our communities to instantly receive the most important news, reports, and analysis from the aquaculture industry.

Further advances

The technology in the prototype is based on the use of near-infrared spectroscopy (NIR). The prototype is unique in its capability to measure extremely quickly AND to probe deeply into foods, e.g. penetrate salmon skin, without contact with the food.

“We have previously developed rapid measuring instruments for use on production lines, but these were unable to penetrate deepenough into products with dark surfaces like salmon and potato skin. We have developed instruments that can penetrate dark surfaces, but these needed to have contact with the food, and were therefore unsuitable for measurements in the production line. In this project, we are working towards combining both of these desirable effects, and this will save food manufacturers a lot of money,” says Jens Petter Wold.

The three companies involved in the project have calculated that the use of an effective instrument can lead to considerable annual savings, based on better yields, consistent product quality,less waste and added value in the market.

”Today we have a promising prototype, and we believe and hope that this will eventually become a commercial product. TOMRA is the technology supplier and the instrument is based on some of their technology. We hope the results will be so good that TOMRA will commercialise it to the benefit of the food industry,” concludes Jens Petter Wold.

FACTS ABOUT THE RESEARCH

SmartSensor is a three-year cross-sectoral innovation project that began in 2016. It is funded by BIONÆR and the participating companies. The complete name of the project is ”Smart Sensor for Innovative Industrial Food Process Control.” The companies participating are Nortura (project manager), Findus, Cermaq and TOMRA. The final objective is that TOMRA will commercialise the instrument developed in the project. The R&D partners are Nofima, which is in charge of the scientific work and the instrument calibration and testing, and SINTEF Digital, which is responsible for developing the instrument itself. They work together in cooperating with each company on testing the instrument in the production process.

Contact person

Jens Petter Wold

Senior Scientist

Phone: +47 959 79 749

jens.petter.wold@nofima.no

Source: Nofima

Editor at the digital magazine AquaHoy. He holds a degree in Aquaculture Biology from the National University of Santa (UNS) and a Master’s degree in Science and Innovation Management from the Polytechnic University of Valencia, with postgraduate diplomas in Business Innovation and Innovation Management. He possesses extensive experience in the aquaculture and fisheries sector, having led the Fisheries Innovation Unit of the National Program for Innovation in Fisheries and Aquaculture (PNIPA). He has served as a senior consultant in technology watch, an innovation project formulator and advisor, and a lecturer at UNS. He is a member of the Peruvian College of Biologists and was recognized by the World Aquaculture Society (WAS) in 2016 for his contribution to aquaculture.