Bremen, Germany – A cooperation between Jacobs University and Kaesler Nutrition GmbH, which is doing research in Bremerhaven, could lead to a saving of several ten thousand tons of phosphorus emissions. The aim of the research project is the more environmentally friendly production of the enzyme phytase and its optimization. Phytase is used to produce feed for aquaculture. The research project is funded by the European Regional Development Fund (ERDF) and the state of Bremen through the BIS Bremerhavener Gesellschaft für Investitionsförderung und Stadtentwicklung mbH (Bremerhaven Economic Development Company). The total funding amounts to 740.000 euros.

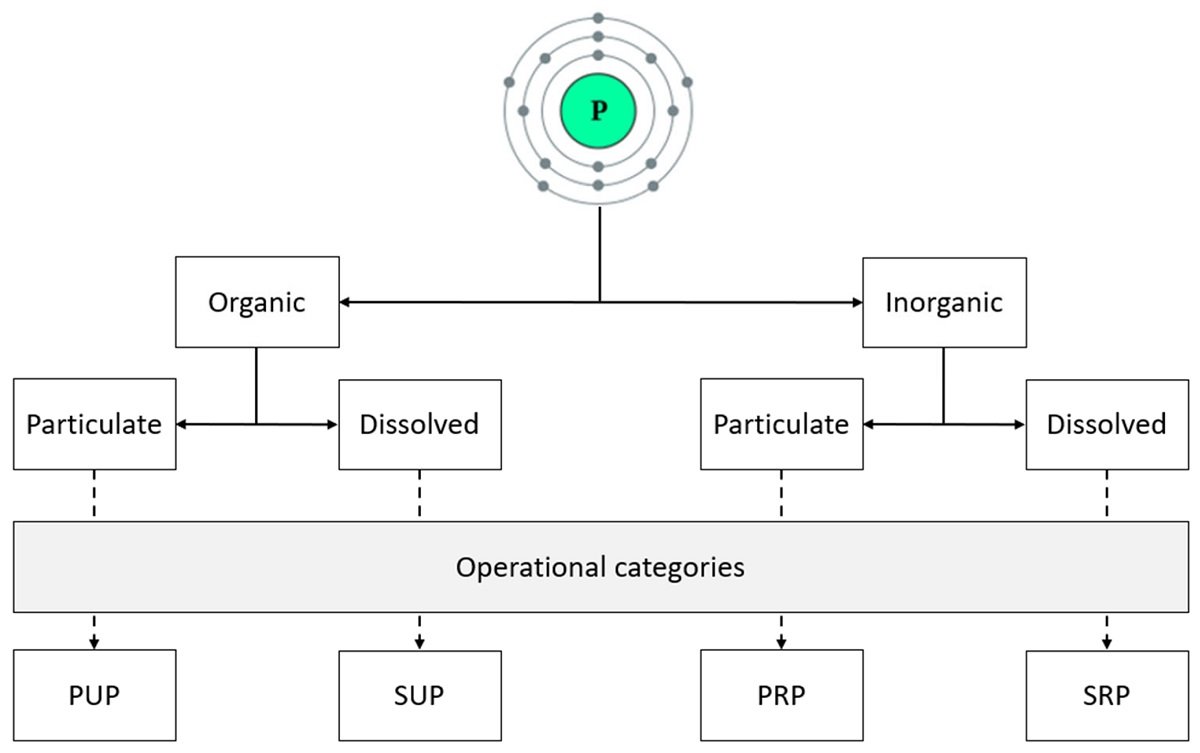

Most animal feeds consist of about 90 percent plant components. However, fish and other farm animals cannot absorb the phosphates contained in the feed. Additionally, they need the enzyme phytase, which is widely added to the feed. The enzyme breaks down phosphate from a plant storage material and makes it available to farm animals. The more successful this is, the more it is possible to forego the addition and thus the extraction of mineral phosphorus. This is a finite resource whose deposits have built up over millions of years, similar to crude oil.

The team of scientists at Jacobs University is now working on improving the industrially relevant properties of the enzyme, but also to make its production process more environmentally friendly. Phytase has to withstand high temperatures during its production, but is fed to the fish at low temperatures. It must therefore be heat-stable and efficient in cold conditions. “If it works more efficiently at low temperatures, not only does less inorganic phosphate have to be fed, but the animals also excrete smaller amounts of phosphate,” explained Ulrich Kleinekathöfer, Professor of Theoretical Physics at Jacobs University. This also has a positive effect on the water quality, and the risk of eutrophication is reduced.

While Kleinekathöfer uses computer simulations to research the improvement of the enzyme structure, Elke Nevoigt, Professor of Molecular Biotechnology, is working on the production process of the enzyme. It is produced in a yeast. Nevoigt plans to use the substrate glycerol instead of methanol, which is the standard up to now. “This is less harmful to the environment,” she said. The expert in the field of yeast research appreciates the project not only because it expands her field of nuclear research, but also because she is cooperating with a company from Bremerhaven, a city nearby.

The theoretical physicist Kleinekathöfer agrees. “To modify an enzyme so that it has certain properties is academically interesting. But I’m also interested in the practical application and the environmental aspect.” Kaesler Nutrition GmbH calculates that over the course of ten years, 35,000 tons of phosphorus emissions could be saved in the field of aquaculture and up to 7,600 tons in agriculture.

Questions are answered by:

Prof. Dr. Elke Nevoigt

Professor of Molecular Biotechnology

Email: e.nevoigt@jacobs-university.de

Prof. Dr. Ulrich Kleinekathöfer

Professor of Theoretical Physics

Email: u.kleinekathoefer@jacobs-university.de

Stay Always Informed

Join our communities to instantly receive the most important news, reports, and analysis from the aquaculture industry.

Editor at the digital magazine AquaHoy. He holds a degree in Aquaculture Biology from the National University of Santa (UNS) and a Master’s degree in Science and Innovation Management from the Polytechnic University of Valencia, with postgraduate diplomas in Business Innovation and Innovation Management. He possesses extensive experience in the aquaculture and fisheries sector, having led the Fisheries Innovation Unit of the National Program for Innovation in Fisheries and Aquaculture (PNIPA). He has served as a senior consultant in technology watch, an innovation project formulator and advisor, and a lecturer at UNS. He is a member of the Peruvian College of Biologists and was recognized by the World Aquaculture Society (WAS) in 2016 for his contribution to aquaculture.