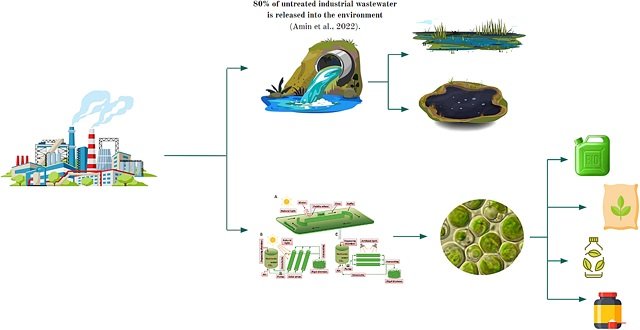

Currently, there is a greater need for more sustainable production processes and advancing towards waste-free manufacturing. Some industries with a significant amount of effluents belong to agribusiness, food, and beverages.

Microalgae have been used as an alternative to traditional remediation techniques, with the advantage of generating high-value added products.

A team of researchers from the Tecnológico de Monterrey and the Technical University of Denmark published a scientific review providing a roadmap on the use of microalgae regarding biomass productivity, biomass concentration, nitrogen and phosphorus removal, chemical oxygen demand, and percentages of lipids, proteins, and carbohydrates.

The purpose of the publication is to guide academics and industrial stakeholders in decision-making to further optimize and valorize their secondary streams (effluents).

Effluent treatment using microalgae

In the last decade, there has been an increasing interest in the scientific community to understand how to use microalgae for effluent treatment.

The main advantages of microalgae treatment, compared to traditional water treatment methods and the use of other organisms for bioremediation, are their great adaptability to adverse conditions, their resistance to toxic or hazardous materials, and relatively low associated costs compared to other methods.

Additionally, microalgae are widely known for accumulating considerable amounts of lipids, making them of great interest to the biofuel industry, and they generate high-value proteins, which are also relevant in the nutraceutical and food markets.

There are four main mechanisms through which microalgae achieve bioremediation: biosorption, bioaccumulation, intracellular biodegradation, and extracellular biodegradation; each of these processes targets specific groups of compounds.

Effect of microalgae genus on production

Biomass production is an important parameter for measuring the cost of a bioprocess. The ranges for biomass concentration vary widely depending on the species and cultivation conditions, as well as the composition of the effluents. It has been observed that biomass concentration fluctuates between 0.2 and 4.25 g.L-1.

Stay Always Informed

Join our communities to instantly receive the most important news, reports, and analysis from the aquaculture industry.

According to the authors of the study, the genus seems to have a high effect on the experiment outcome, as most of the data points corresponding to Chlorella sp. are generally higher.

“There is a higher number of data points regarding biomass concentration for Chlorella, compared to other genera, which are above average,” they reported.

Advancements in the production of high-value products

In addition to using effluents as a growth medium, the valorization of effluents is also a relevant topic to be studied. The production of lipids, proteins, and carbohydrates by microalgae can add extra value to their cultivation.

“Nowadays, more biorefineries are using microalgae strains such as Chlorella, Scenedesmus, Dunaliella, etc., as they can be cultivated under autotrophic, heterotrophic, and mixotrophic conditions and have minimal nutrient requirements,” they emphasized.

Nutrient removal efficiency

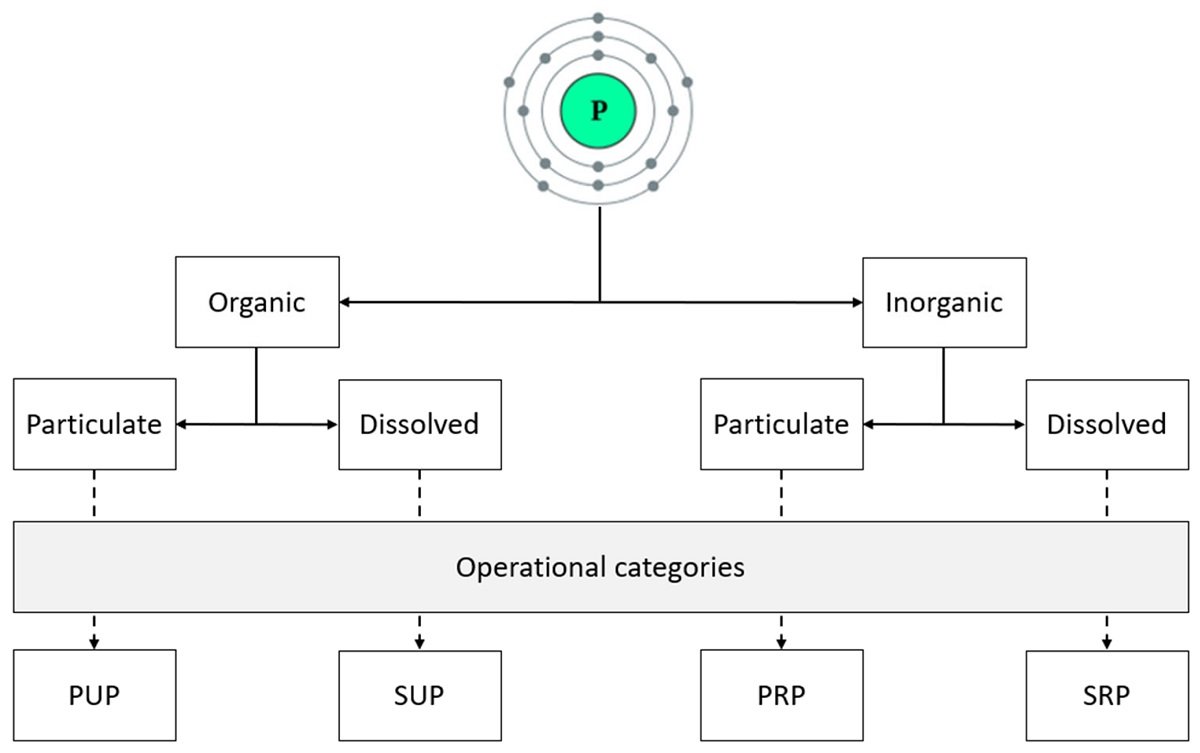

Microalgae can also be used to remove nutrients from effluents. The main nutrients targeted include nitrogen, phosphorus, and chemical oxygen demand.

The main indicators for bioremediation are the percentages of total nitrogen removal, total phosphorus removal, and chemical oxygen demand removal.

According to the study, the average removal rate for nitrogen was 71.54%, for phosphorus 74.76%, and 71.58% for chemical oxygen demand. The researchers report that “due to the variability shown in the study results, nutrient removal efficiencies do not appear to have a linear relationship with biomass productivity performance.”

Conclusion

“The use of industrial effluents as a growth medium for microalgae has been widely explored; however, limitations still persist regarding the available data for larger scales,” conclude the authors of the study.

They also highlight that integrating bioremediation with microalgae in the industry and developing value-added products could increase sustainability and profitability.

“Based on the collected data, it can be affirmed that the growth of microalgae is greatly affected by the species, the type of wastewater, and the processes prior to cultivation,” they emphasize.

Finally, the researchers highlight that limitations in microalgae production systems can be overcome through scientific advancements, such as genetic engineering, that promote a circular economy.

Contact

Seyed Soheil Mansouri

Department of Chemical and Biochemical Engineering

Technical University of Denmark

Søltofts Plads, Building 228A, 2800 Kongens Lyngby, Denmark

Email:seso@kt.dtu.dk

Reference (open access)

Sandra Beatriz Castillo Castañeda, Rafael Emilio Altamirano Torres, Miguel Ángel Domínguez Vizcaíno, Elda M. Melchor-Martínez, Mariel Araceli Oyervides-Muñoz, Juan Eduardo Sosa Hernandez, Roberto Parra-Saldívar, Thomas Bisgaard, Omid Tavakoli, Irini Angelidaki, Solange I. Mussatto, Eduardo Krebs Kleingesinds, Seyed Soheil Mansouri. 2023. Valorizing industrial side streams through microalgae cultivation: A roadmap for process scale-up, Algal Research, Volume 74, 2023, 103177, ISSN 2211-9264, https://doi.org/10.1016/j.algal.2023.103177.

Editor at the digital magazine AquaHoy. He holds a degree in Aquaculture Biology from the National University of Santa (UNS) and a Master’s degree in Science and Innovation Management from the Polytechnic University of Valencia, with postgraduate diplomas in Business Innovation and Innovation Management. He possesses extensive experience in the aquaculture and fisheries sector, having led the Fisheries Innovation Unit of the National Program for Innovation in Fisheries and Aquaculture (PNIPA). He has served as a senior consultant in technology watch, an innovation project formulator and advisor, and a lecturer at UNS. He is a member of the Peruvian College of Biologists and was recognized by the World Aquaculture Society (WAS) in 2016 for his contribution to aquaculture.