Shrimp aquaculture is a booming industry, but maintaining water quality in intensive systems can be a challenge. Biofloc technology (BFT) has emerged as a promising solution, yet controlling biofloc accumulation during later stages is crucial for optimal shrimp growth and economic performance.

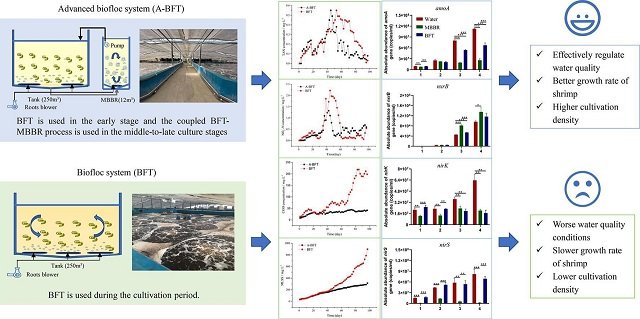

A recent study published in Aquaculture by researchers from Tongji University, the Chinese Academy of Fisheries Sciences, and the Yancheng Institute of Technology presents a groundbreaking advancement: the Advanced Biofloc System (A-BS). This innovative approach integrates a Moving Bed Biofilm Reactor (MBBR) with traditional BFT, resulting in significant improvements in water quality and shrimp health.

The Potential of Moving Bed Biofilm Reactors

MBBRs are wastewater treatment technologies that use suspended carrier media to support biofilm growth. They have been integrated into aquaculture systems for effluent purification and water recycling. In BFT systems, MBBRs can offer:

- Enhanced biological filtration: Removal of organic and inorganic contaminants from the water.

- Balanced microbial communities: Combining autotrophic and heterotrophic bacteria for better nitrogen removal.

- Biofloc regulation: Control of aeration to manage biofloc formation.

The Advanced Biofloc System (A-BS)

To assess the benefits of integrating MBBRs with BFT, the researchers conducted a pilot-scale study comparing an Advanced Biofloc System (A-BS) to a traditional BFT system. The study focused on:

- Water quality: Evaluating changes in key parameters such as ammonia, nitrite, and suspended solids.

- Shrimp growth: Comparing shrimp growth performance in both systems.

- Microbial communities: Analyzing bacterial composition and nitrogen-related functional genes in MBBR, water, and biofloc.

The A-BS group achieved significantly better results:

- Reduced water contaminants: Key water quality indicators like ammonia, nitrite, chemical oxygen demand, and suspended solids were substantially lower in the A-BS group, especially during the critical middle and late stages of culture.

- Improved shrimp growth: The A-BS group promoted a higher final population density (shrimp per cubic meter) and superior survival rates compared to the control group.

These findings suggest that A-BS effectively maintains water quality throughout the cultivation cycle, leading to healthier and more productive shrimp populations.

Unveiling the Science Behind the Success

The research team delved deeper into analyzing microbial communities within the systems. A-BS exhibited:

- Higher bacterial abundance and diversity: This rich microbial ecosystem supports a healthy environment for shrimp.

- Greater presence of beneficial genes: Genes associated with denitrification (removal of ammonia and nitrite) were significantly more abundant in the A-BS group. Additionally, the integration of MBBRs amplified key genes that maintain water quality stability during the later stages (amoA and nirK).

The combination of MBBR and BFT in A-BS appears to create a robust microbial community that efficiently manages waste, promoting optimal conditions for shrimp growth.

A Sustainable Future for Shrimp Aquaculture

The A-BS system represents a significant advancement in shrimp aquaculture. By combining the strengths of BFT and MBBR technology, it offers a sustainable and efficient approach to shrimp production. The findings from this study provide valuable insights for the future development and implementation of A-BS systems in commercial shrimp farming.

Stay Always Informed

Join our communities to instantly receive the most important news, reports, and analysis from the aquaculture industry.

This proof-of-concept study paves the way for significant progress in shrimp aquaculture. By offering better water quality, higher yields, and a deeper understanding of the underlying microbial processes, the A-BS system holds great promise for:

- Sustainable shrimp farming: Efficient waste management and reduced environmental impact.

- Increased profitability for shrimp producers: Improved growth and survival rates translate into higher yields.

- Modernization of the industry: A-BS provides a strategic pathway towards more efficient and environmentally friendly shrimp aquaculture practices.

The study was funded by the National Key Research and Development Program of China and the Central Public-Interest Scientific Institution Basal Research Fund, CAFS.

Contact

Yalei Zhang

College of Environmental Science and Engineering, Tongji University

Chifeng Road 63, Shanghai 200092, China.

Email: zhangyalei@tongji.edu.cn

Reference

Zhang, H., Cao, X., Wu, X., Yu, Y., Zhang, Y., Yang, L., & Zhang, Y. (2025). Pilot-scale investigation of an advanced biofloc technology for treating Pacific white shrimp effluent: Performance and insight mechanisms. Aquaculture, 595, 741552. https://doi.org/10.1016/j.aquaculture.2024.741552

Editor at the digital magazine AquaHoy. He holds a degree in Aquaculture Biology from the National University of Santa (UNS) and a Master’s degree in Science and Innovation Management from the Polytechnic University of Valencia, with postgraduate diplomas in Business Innovation and Innovation Management. He possesses extensive experience in the aquaculture and fisheries sector, having led the Fisheries Innovation Unit of the National Program for Innovation in Fisheries and Aquaculture (PNIPA). He has served as a senior consultant in technology watch, an innovation project formulator and advisor, and a lecturer at UNS. He is a member of the Peruvian College of Biologists and was recognized by the World Aquaculture Society (WAS) in 2016 for his contribution to aquaculture.