Global demand for fish and seafood has reached an all-time high. With a population projected to exceed 10 billion people by 2100, the pressure on traditional fishing and aquaculture systems is immense. Overfishing, which already affects more than 37% of assessed stocks, and the degradation of marine habitats threaten the planet’s ability to meet this growing need for protein.

In this context, an innovative technology known as cellular aquaculture or lab-grown fish is emerging, which proposes to produce seafood products directly from cells. A recent and exhaustive study published in npj Science of Food by researchers from the Joint Research Centre (JRC) of the European Commission has analyzed 40 scientific articles to create a complete map of this emerging sector, evaluating everything from its technology to its economic and regulatory viability. Below, we break down the key findings of this review to understand how close or far we are from seeing these products in our market.

What exactly is cellular aquaculture?

Cellular aquaculture is a production method that cultivates cells from marine animals in a controlled environment, such as a bioreactor, to create muscle and fat tissue identical to that of conventional fish or seafood. The process, in theory, is simple:

- Cell Sourcing: It begins with a small sample of cells from a fish or shellfish, ideally cell lines that can be propagated repeatedly.

- Bioreactor Cultivation: The cells are placed in a bioreactor, a closed system that provides them with a nutrient-rich growth medium to multiply.

- Use of Scaffolding: To help the cells form a three-dimensional structure that mimics the texture of real tissue, “scaffolds” are used, which are often edible and biodegradable.

This approach could avoid many of the environmental problems associated with traditional fishing and aquaculture. However, the cultured seafood industry is considerably less mature than its cultured meat counterpart, although interest from investors and governments is growing rapidly.

An emerging but booming sector

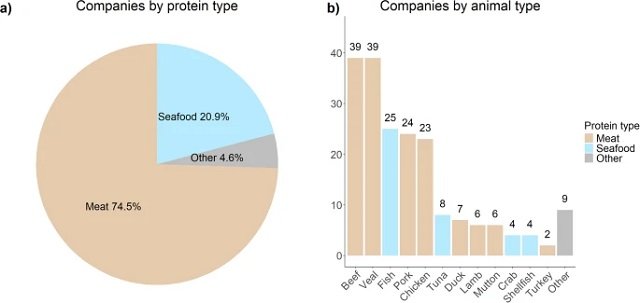

Although the first study on the topic dates back to 2002, the real momentum has occurred in recent years. Currently, there are 25 companies worldwide researching or manufacturing cultured seafood products, and the majority (10 out of 16 companies analyzed) began their activities from 2020 onwards.

Geographically, the United States (24%) and Singapore (16%) lead in the number of companies, which reinforces the idea that a favorable regulatory framework is key for commercialization. Unlike cultured meat, which focuses mainly on beef, chicken, and pork, the seafood sector concentrates on fish, tuna, crab, and seafood in general.

The six major fronts of cultured seafood

The study identifies six key areas that will define the success or failure of this industry.

Technological advances and challenges

The main bottleneck is technology. Most cellular research has focused on terrestrial species, leaving a significant gap in aquatic organisms.

- Cell lines: There is a very limited availability of stable and public cell lines for commercially relevant seafood species. Research has focused on model fish like zebrafish, which is not widely consumed, although the findings could be transferable.

- Growth media: The most common medium, Fetal Bovine Serum (FBS), is extremely expensive and presents ethical dilemmas. Finding affordable, animal-free alternatives is a priority. Some companies claim to have achieved this, but the formulations are secret.

- Scaffolding and scaling: Creating edible scaffolds that allow for proper oxygenation and nutrition of the cells is a challenge, especially for products thicker than 200 µm. 3D bioprinting is promising but still underdeveloped for food. Furthermore, moving from small laboratory bioreactors to large-scale industrial production remains a major hurdle.

Public health perspectives

This is where cultured fish could shine.

Stay Always Informed

Join our communities to instantly receive the most important news, reports, and analysis from the aquaculture industry.

- Potential benefits: By being produced in a sterile and controlled environment, contaminants such as heavy metals (mercury, lead), microplastics, and pathogens can be eliminated. The nutritional profile could even be improved by increasing omega-3 fatty acids.

- Concerns: Doubts arise about the safety of the ingredients used in growth media and scaffolds, which do not have a history of food use. The genetic stability of the cells must also be guaranteed to avoid long-term risks and ensure the final nutritional profile is comparable or superior to that of conventional seafood.

Consumer acceptance

This is, perhaps, the most decisive factor. Specific research on cultured seafood is limited, but it is assumed that attitudes will be similar to those for cultured meat.

- Key factors: The taste, texture, and appearance must be nearly identical to the traditional product. The product’s name also has an influence; “cell-based seafood” has been identified as the most favorable term in English-language studies, as it is perceived as transparent and accurate.

- Varied attitudes: While some consumers, especially younger ones, show curiosity and a willingness to try it, others feel distrust due to the product’s “unnaturalness.” Interestingly, concern about contaminants in traditional fish could tip the balance in favor of the cultured option.

Environmental impact: a sustainable solution?

Although it is promoted as an alternative to relieve pressure on the oceans, its sustainability is still under debate.

- Arguments in favor: It could reduce overfishing and decrease the carbon footprint of transportation by allowing for localized production near consumer markets.

- Arguments against: Cellular production is very energy-intensive. If that energy comes from fossil fuels, its global warming potential could be higher than that of conventional aquaculture and fishing.

Economic viability

The cost of production is currently the biggest impediment to competing with traditional seafood.

- Prohibitive costs: In 2019, producing cultured shrimp dumplings cost $5,000 per kilogram. These costs, driven by R&D, expensive growth media, and highly specialized labor, are decreasing but remain high. It is estimated that producing 1 kg of generic cultured meat can cost from $150 to over $22,000.

- Investment: Funding comes mostly from private venture capital, although major players in the traditional food industry, such as Vietnam’s Vinh Hoan, are already investing in cultured seafood startups.

The regulatory landscape

The legal framework is a fragmented and underdeveloped mosaic. As of the date of the study, no country has authorized the sale of cultured seafood, although cultured meat has been approved in countries like Singapore and the U.S.

- Regional differences: Singapore has been a pioneer with a proactive approach. The European Union considers it a “Novel Food,” which requires a rigorous safety assessment, but some countries like Italy have already banned its production. In the U.S., regulation is shared between the FDA and the USDA.

Conclusion: a promising future but with a long way to go

Lab-grown fish and seafood are presented as a technology with the potential to complement fishing and aquaculture to ensure future food security. However, this review makes it clear that the industry is in a very early stage.

It is not a magic solution, but rather another piece in the complex puzzle of global food supply. Its success will depend on overcoming enormous technological and economic challenges, establishing clear and transparent regulatory frameworks, and, above all, winning the trust and acceptance of the consumer. Collaboration among scientists, companies, and regulators will be essential for cellular aquaculture to move from a promise to a reality on our plates.

Contact

Antonio Borriello

Joint Research Centre (JRC), European Commission

Ispra, VA, Italy

Email: antonio.borriello@ec.europa.eu

Andrea Pierucci

Joint Research Centre (JRC), European Commission

Ispra, VA, Italy

Email: andrea.pierucci@ec.europa.eu

Reference (open access)

Borriello, A., Pierucci, A. A global comprehensive review on cultured seafood. npj Sci Food 9, 142 (2025). https://doi.org/10.1038/s41538-025-00461-4

Editor at the digital magazine AquaHoy. He holds a degree in Aquaculture Biology from the National University of Santa (UNS) and a Master’s degree in Science and Innovation Management from the Polytechnic University of Valencia, with postgraduate diplomas in Business Innovation and Innovation Management. He possesses extensive experience in the aquaculture and fisheries sector, having led the Fisheries Innovation Unit of the National Program for Innovation in Fisheries and Aquaculture (PNIPA). He has served as a senior consultant in technology watch, an innovation project formulator and advisor, and a lecturer at UNS. He is a member of the Peruvian College of Biologists and was recognized by the World Aquaculture Society (WAS) in 2016 for his contribution to aquaculture.